Bamboo-wood composite modified material

A modified material, bamboo-wood composite technology, applied in the field of wood, can solve problems such as inappropriate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

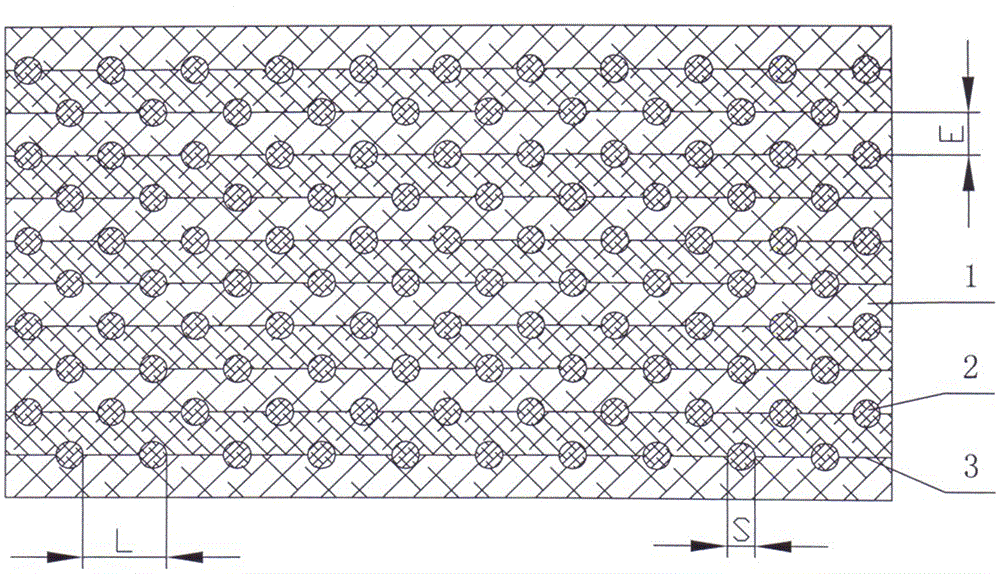

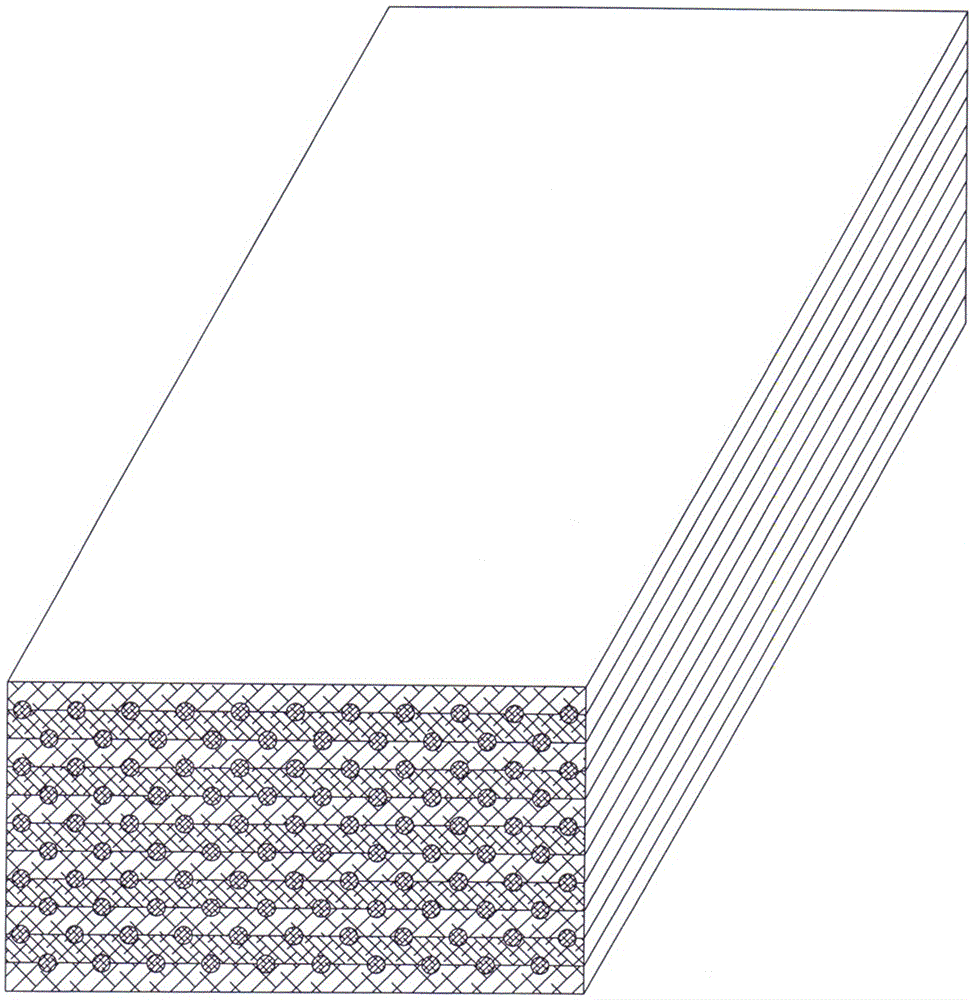

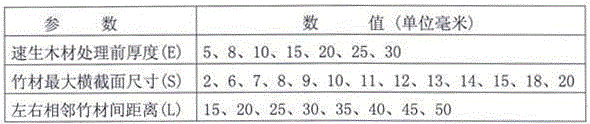

[0020] figure 1 It is a schematic diagram of the modified material structure of bamboo and wood composite before the modification treatment. It can be seen from the figure that it includes multi-layer sheet-like fast-growing wood 1, and the fast-growing wood 1 is poplar or eucalyptus or pine or willow, etc. . Between the multi-layer sheet-like fast-growing wood 1, the row-shaped strips of bamboo 2 that are placed at intervals may be other shapes of polygons such as rectangles, triangles, pentagons, hexagons, or trapezoids in addition to circles. . The fiber direction of the bamboo 2 is consistent with the length direction of the bamboo 2, wherein: the thickness of the layered fast-growing wood 1 is E before the modification treatment; the size of the largest cross section of the bamboo 2 is S; the left and right adjacent bamboo 2 The distanc...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Size | aaaaa | aaaaa |

| Air dry density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com