Multi-reel take-up machine

A technology of a wire take-up machine and a wire take-up reel, which is applied in the field of tin-based alloy wire manufacturing, can solve the problems of untimely collection, blocked molds, and high speed, and achieves the effect of simple structure and convenient use.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

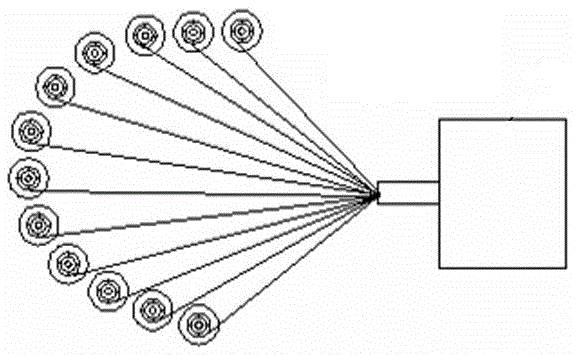

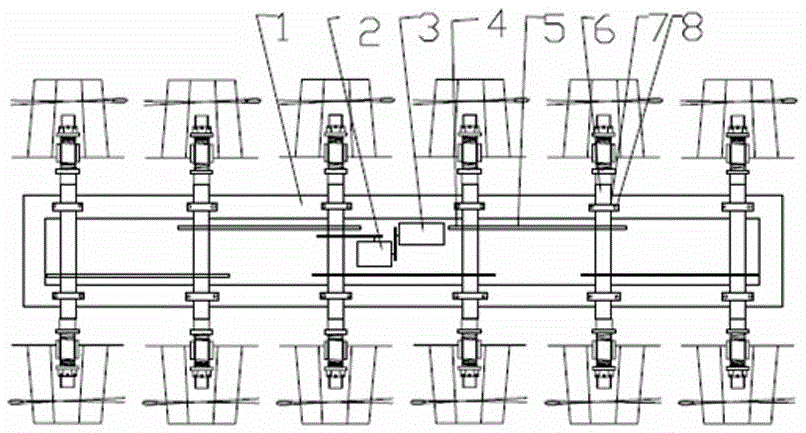

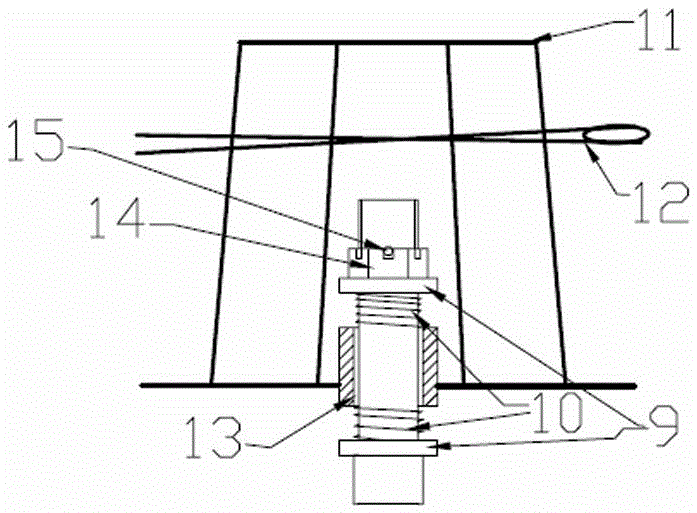

[0020] Example: see figure 2 , 3 , a multi-disc wire take-up machine according to the present invention, comprising a frame 1, a reducer 2, a motor 3, a sprocket 4, a chain 5, a drive shaft 6, a bearing 7, a bearing seat 8, a baffle plate 9, and a spring 10 , Take-up reel 11, scissors insert 12, axle sleeve 13, nut 14, positioning pin 15.

[0021] The take-up machine is symmetrically arranged with 12 take-up reels 6, each take-up reel 6 has a scissors insert 12, the material of the transmission shaft 6 is 40Cr steel, the hardness is HRC48, and the beam on the frame 1 is used to fix the transmission shaft 6 It forms an angle of about 5° with the horizontal plane. There is a positioning slot on the nut 14 and a positioning hole on the drive shaft 6. The unloaded winding speed of the take-up reel 11 is about 2.55m / min. taper.

[0022] Tension adjustment process: determine the tension when the tin-based alloy wire is smoothly collected through the test, idle the wire take-up m...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com