Unit figure of LED photonic crystal structure and use method thereof

A photonic crystal and pattern technology, applied in the field of integrated circuit equipment manufacturing, can solve the problems of low luminous efficiency and no directionality, and achieve the effect of optimizing the photolithography process and meeting the large size

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0051] Specific embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings.

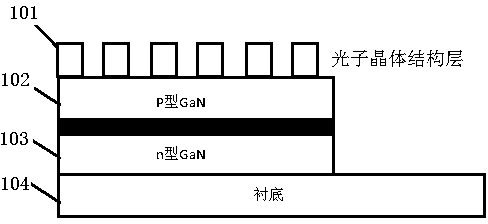

[0052] The process sequence of the LED photonic crystal process layer in the prior art is divided into four steps, including making the LED chip substrate, depositing the photonic crystal process layer, forming the photonic crystal structure by photolithography, and forming the photonic crystal pattern process layer by etching. The technical scheme of the invention is mainly applied to the photolithography process of the photonic crystal structure layer.

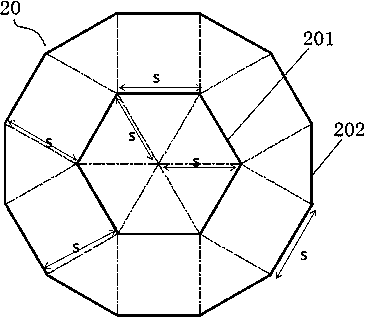

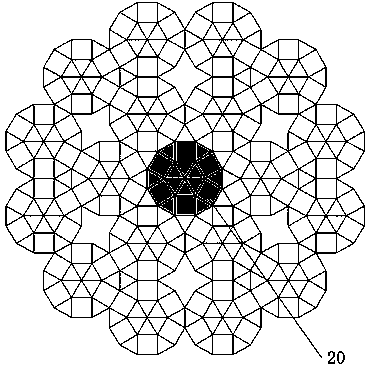

[0053] The lithography process of the photonic crystal structure layer specifically includes: first, glue is applied on the LED substrate sheet with the photonic crystal process layer; The mask plate operation of the pattern, with which the pattern is spliced and exposed according to the stepping or scanning in the X and Y directions; after exposure, the final lithography photonic crystal ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com