Low-cooling-rate-sensitivity high-nucleation-capability AlNbBRE refiner for cast aluminum alloy and preparation method of refiner

A technology of casting aluminum alloy and refining agent, which is applied in the field of refining agent for casting aluminum alloy, can solve the problems of high sensitivity to cooling rate, etc., and achieves low sensitivity to cooling rate, improved mechanical properties, and excellent refining effect. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

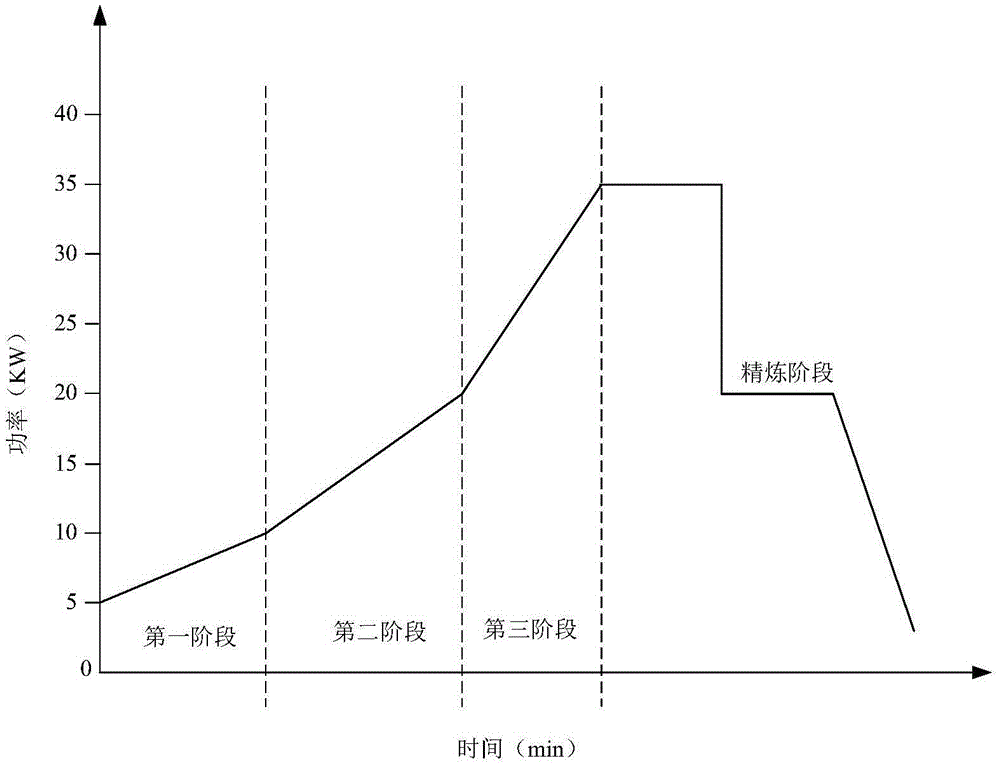

[0075] Preparation of Al-5Nb-B-0.5La-0.5Ce Grain Refiner

[0076] Target ingredients for formulating refiners:

[0077] The target composition of the refiner is Al-5Nb-B-0.5La-0.5Ce;

[0078] Dosage: 3.5Kg of Al-10Nb, 0.07Kg of boron (B) powder with a purity of 99.5% and 0.035Kg of boron (B) powder with a purity of 99.0wt% are required to prepare 7Kg of Al-5Nb-B-0.5La-0.5Ce refiner Metal lanthanum (La), 0.035 Kg of metal cerium (Ce) with a purity of 99.0 wt %, and the remainder of a block of Al with a size of 5×5 cm.

[0079] Ingot mold step;

[0080] Put the graphite ingot mold into the resistance furnace and heat it up to 200°C, keep it warm for 4 hours, then put the fully preheated ingot mold into the induction furnace, and install a sprue cup on the ingot mold, and add magnesium oxide to the sprue cup Ceramic filter, ready to pour. The sprue cup installed with the magnesia ceramic filter is beneficial to the cleanliness of the refiner melt.

[0081] Knot the crucible ...

Embodiment 2

[0099] Preparation of Al-4Nb-B-0.5La-0.5Er Grain Refiner

[0100] Target ingredients for formulating refiners:

[0101] The target composition of the refiner is Al-4Nb-B-0.5La-0.5Er;

[0102] Dosage: To prepare 10Kg of Al-4Nb-B-0.5La-0.5Er refiner, 4Kg of Al-10Nb, 2Kg of Al-5B master alloy block with a purity of 99.5%, and 0.05Kg of metal with a purity of 99.0wt% are required Lanthanum (La), 0.05 Kg of metal erbium (Er) with a purity of 99.0 wt%, and the balance of Al blocks with a size of 5×5 cm. The size of the Al-5B intermediate alloy block is 3×3 cm.

[0103] Ingot mold step;

[0104] Put the graphite ingot mold into the resistance furnace and heat it up to 300°C, keep it warm for 2 hours, then put the fully preheated ingot mold into the induction furnace, and install a sprue cup on the ingot mold, and add magnesium oxide to the sprue cup Ceramic filter, ready to pour. The sprue cup installed with the magnesia ceramic filter is beneficial to the cleanliness of the ref...

Embodiment 3

[0123] Al-3Nb-0.6B-0.5Y-0.5Ce grain refiner

[0124] Target ingredients for formulating refiners:

[0125] The target composition of the refiner is Al-3Nb-0.6B-0.5Y-0.5Ce;

[0126] Dosage: To prepare 7Kg of Al-3Nb-0.6B-0.5Y-0.5Ce refiner, 2.1Kg of Al-10Nb, 0.042Kg of boron (B) powder with a purity of 99.5%, and 0.035Kg of a purity of 99.0wt% are required metal yttrium (Y), 0.035Kg of metal cerium (Ce) with a purity of 99.0wt%, and the remainder of a block of Al with a size of 5×5 cm.

[0127] Ingot mold step;

[0128] Put the graphite ingot mold into the resistance furnace and heat it up to 400°C, keep it warm for 2 hours, then put the fully preheated ingot mold into the induction furnace, and install a sprue cup on the ingot mold, and add magnesium oxide to the sprue cup Ceramic filter, ready to pour. The sprue cup installed with the magnesia ceramic filter is beneficial to the cleanliness of the refiner melt.

[0129] Knot the crucible step;

[0130] In the knotted cru...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Average grain size | aaaaa | aaaaa |

| Average grain size | aaaaa | aaaaa |

| Tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com