Patents

Literature

45results about How to "Reduce performance variance" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Textile Based on a Mixture of Abrasion Resistant Technical Fibers

InactiveUS20070249250A1Difference in performanceExcellent mechanical propertyWarp knittingStraight-bar knitting machinesTemperature resistanceNatural fiber

The invention concerns a single-layer fabric comprising two yarns, a so-called comfort cellulosic material yarn and a technical yarn with high abrasion and temperature resistance properties, said two yarns being woven or knitted so as to define at least two separate portions in the thickness of the fabric, a first outside portion, with a majority of technical yarn, and a second inside portion, with a majority of comfort yarn, said portions being at least partly entangled. The invention is characterized in that the technical yarn, produced from continuous filaments, whereof the web is coated over at least 75% of its surface with a coating comprising at least partly natural fibers.

Owner:PHP

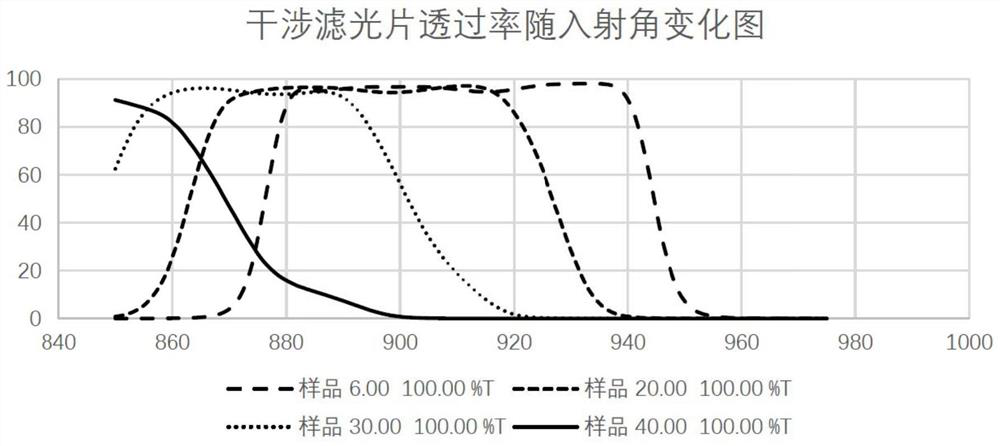

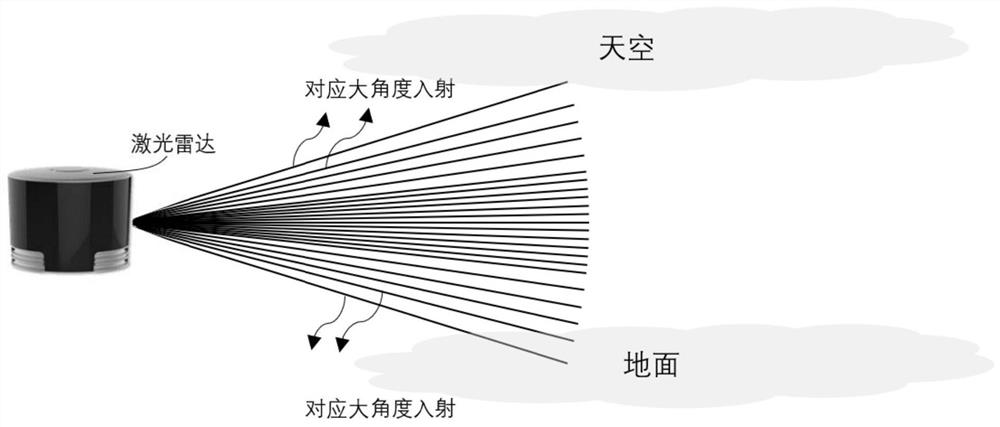

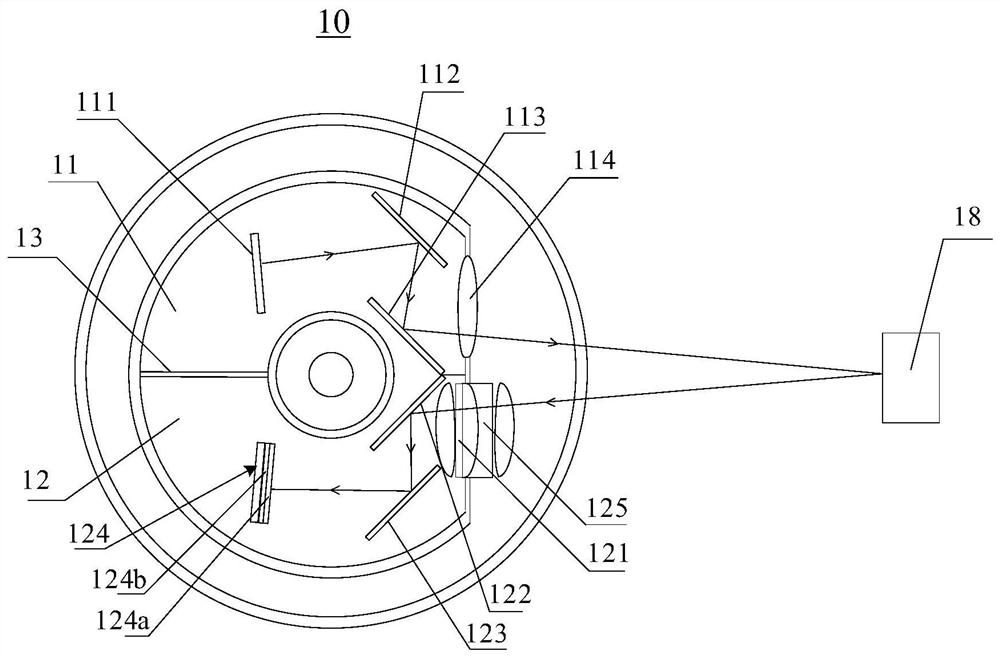

Optical receiving module, and laser radar system

ActiveCN109814082BEnhanced inhibitory effectImprove transmittanceWave based measurement systemsRadar systemsEngineering

The present invention provides an optical receiving module and a laser radar system, the optical receiving module includes: an optical transmission sub-module and a detection sub-module sequentially arranged along the receiving optical path; the optical transmission sub-module is suitable for receiving, filtering, and transmitting light beams, the light beams include signal light; and the detection sub-module is adapted to receive and detect the light beams transmitted by the light transmission sub-module; wherein, the light transmission sub-module and / or the detection sub-module includes absorption type substrate, the absorption type substrate is suitable for absorbing at least light in a predetermined wavelength band outside the wavelength range of the signal light. The laser radar system includes: a light emitting module, adapted to emit a detection laser beam to the outside; and the light receiving module, adapted to receive and detect an echo signal of a laser beam formed by reflecting the detection laser beam from the outside. The light receiving module and the laser radar system of the embodiments of the present invention can suppress ambient light, increase the intensity of obliquely incident signal light at a large angle, and improve the signal-to-noise ratio.

Owner:HESAI TECH CO LTD

Novel anti-pollution flashover coating for ultra and super high voltage insulator

ActiveCN105086820AReduce the temperaturePrevent escapeFireproof paintsAntifouling/underwater paintsSolventSurface-active agents

The invention belongs to the technical field of functional coatings and particularly relates to a novel anti-pollution flashover coating for an ultra and super high voltage insulator. The novel anti-pollution flashover coating comprises, by mass, 40%-50% of room temperature vulcanized silicone rubber, 5%-10% of titanate coupling agent, 2%-6% of composite fire retardant, 5%-12% of modified composite reinforcing agent, 2%-4% of nano TiO2, 0.5%-1% of surface active agent, 1%-5% ofhexamethyldisilazane, 0.2%-0.5% of antifoaming agent, 0.3%-0.6% of catalyst, 0.3%-0.6% of cross-linking agent and the balance solvent. The prepared anti-pollution flashover coating is sprayed on the surface of the cleaned ceramic insulator, and the coating can be used after being naturally cured for 96 hours under the condition of 25 DEG C+ / -2 DEG C and 40%-70% of RH. According to the anti-pollution flashover coating, after the sprayed anti-pollution flashover coating is completely cured, the contact angle is not smaller than 135 degrees.

Owner:ELECTRIC POWER RESEARCH INSTITUTE OF STATE GRID SHANDONG ELECTRIC POWER COMPANY +1

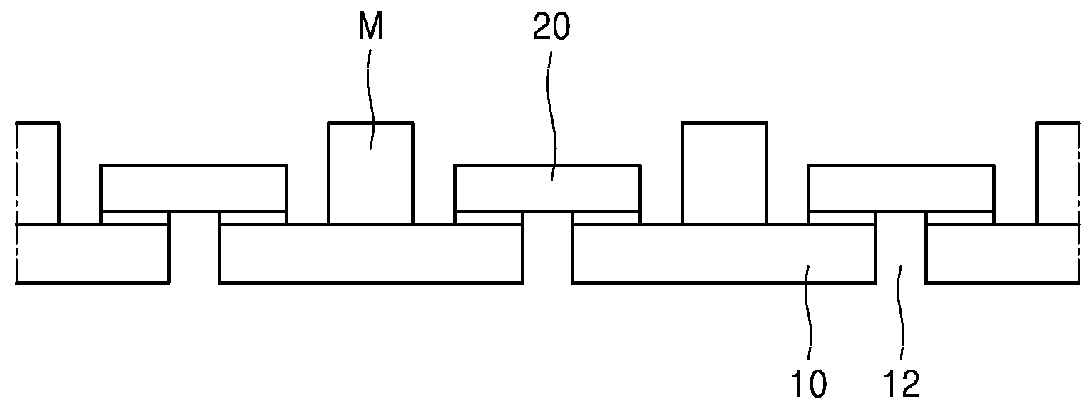

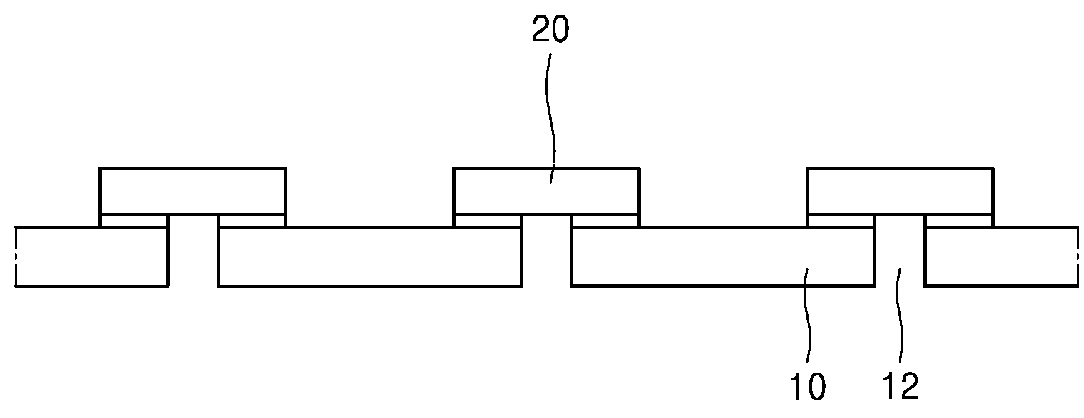

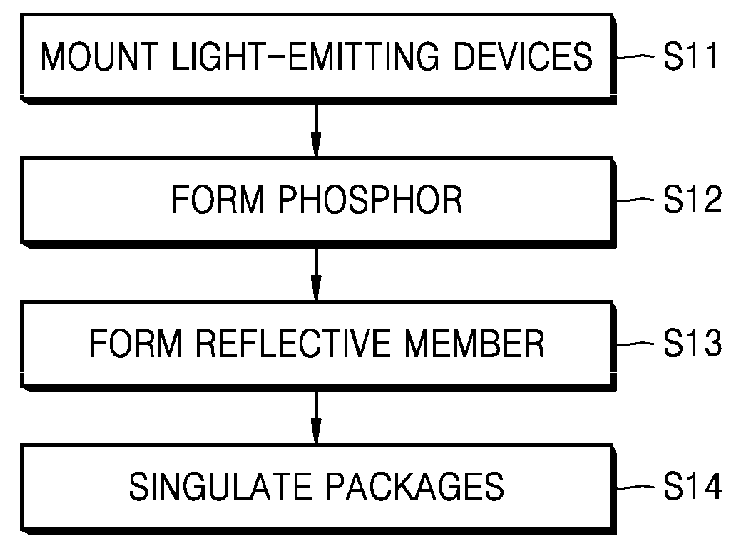

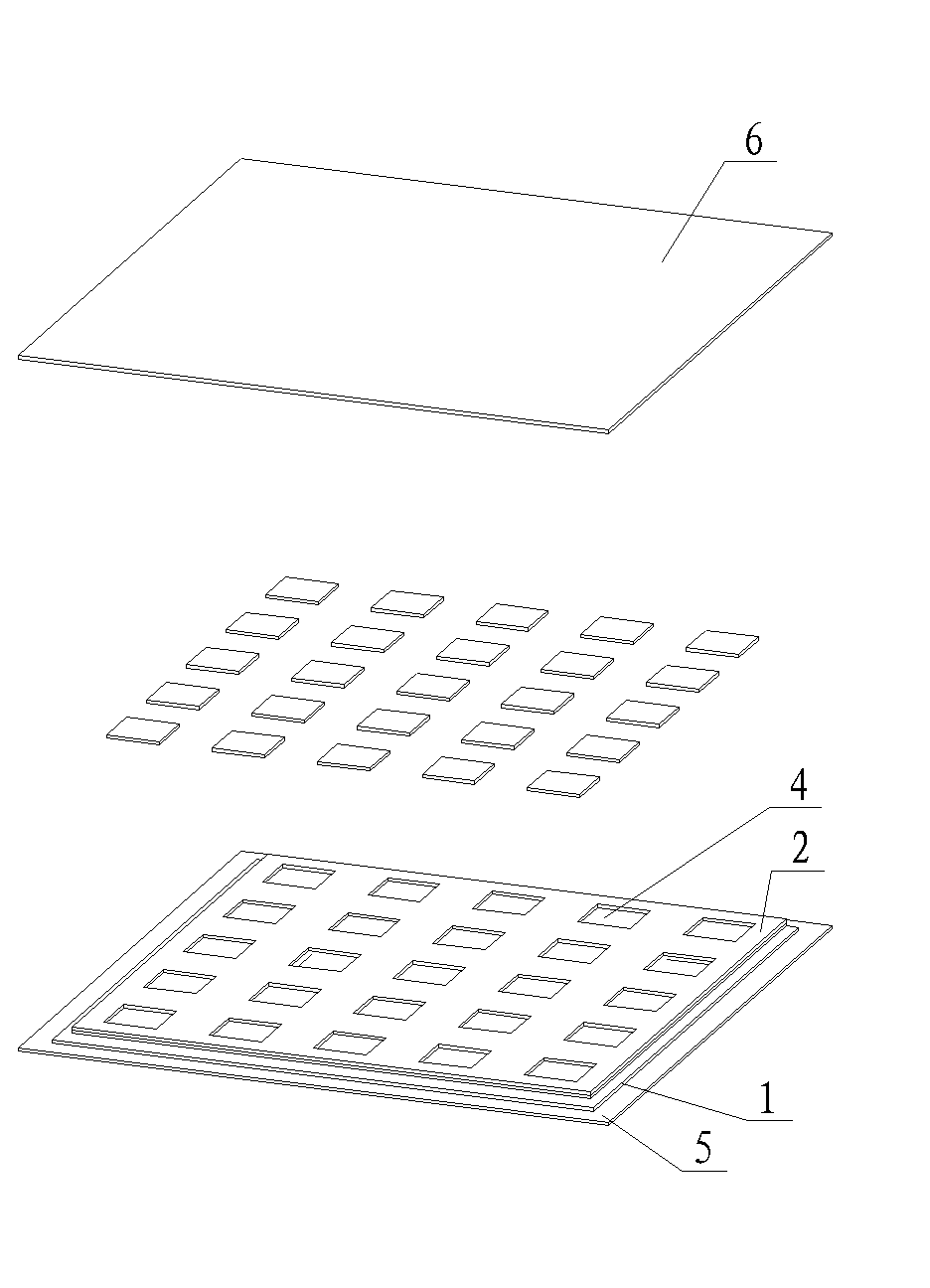

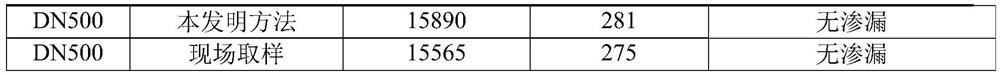

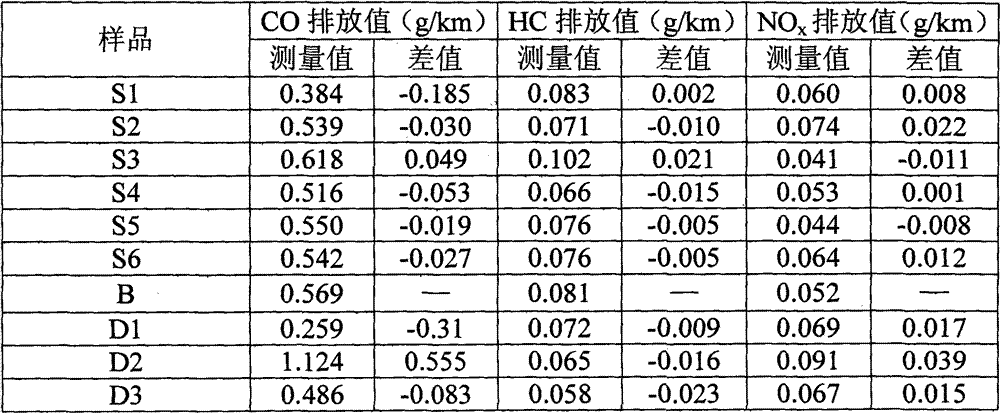

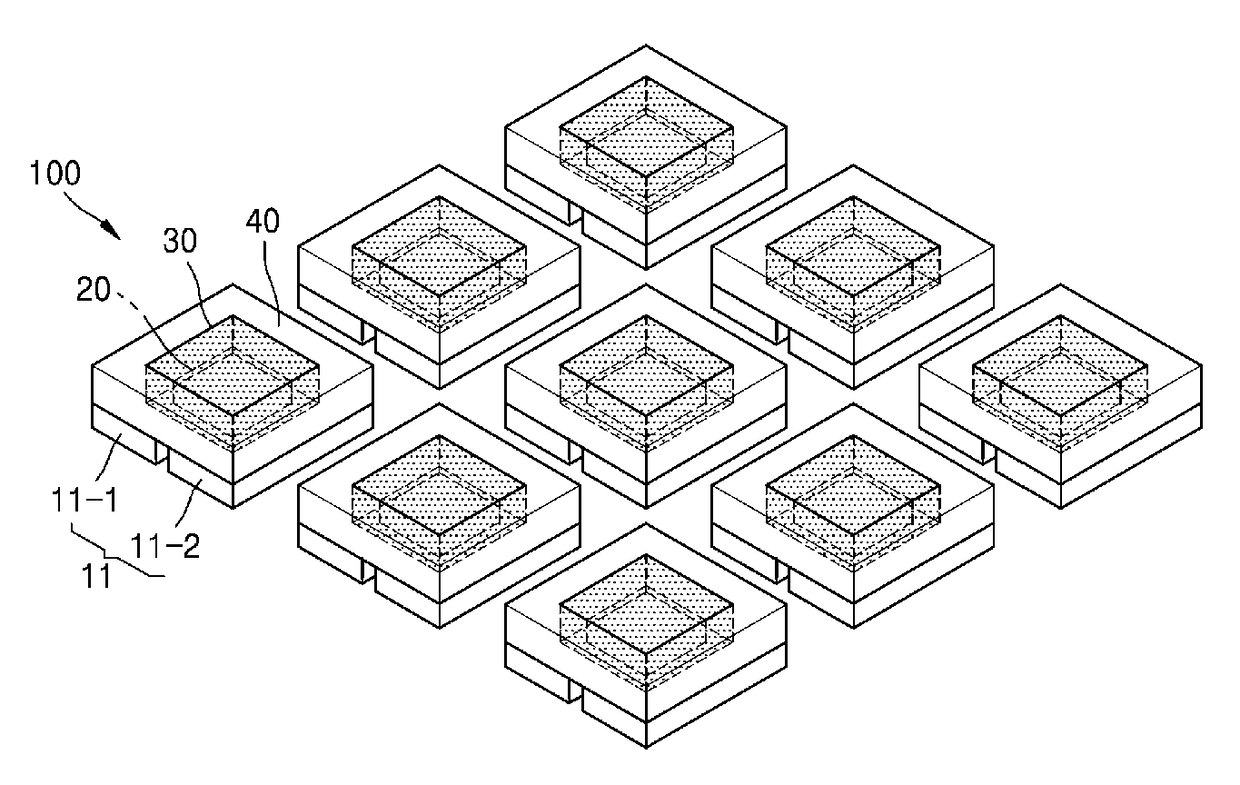

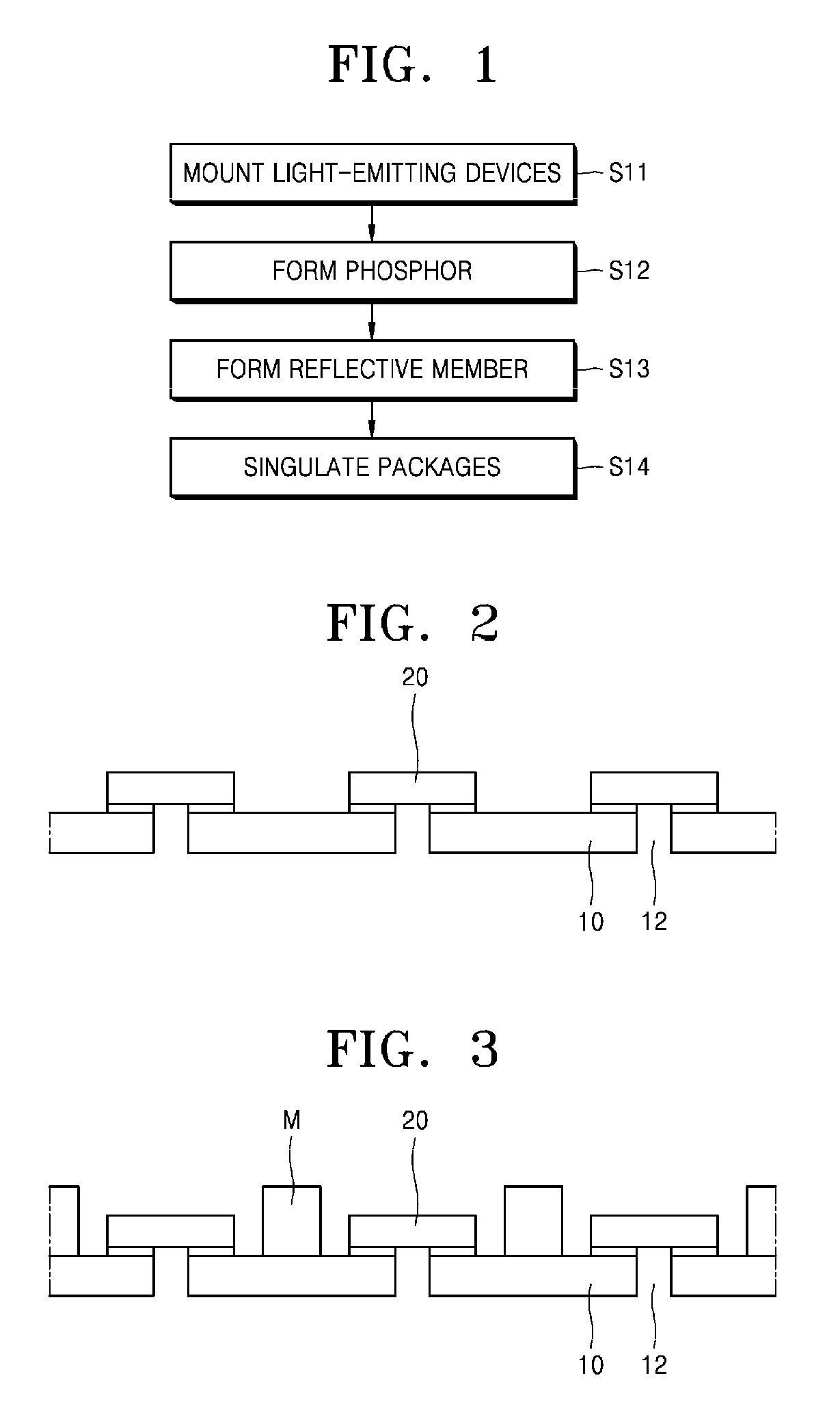

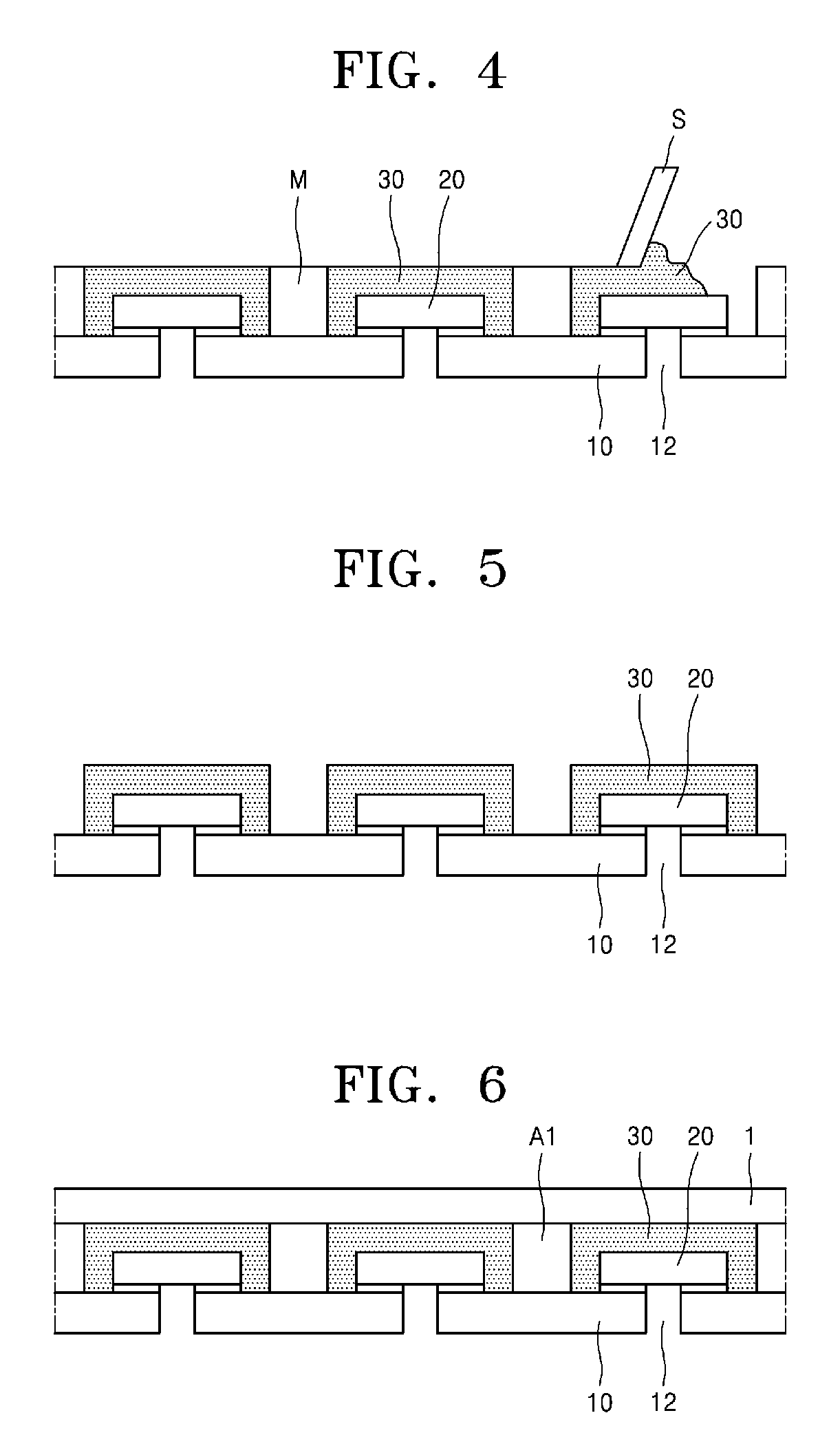

Method for manufacturing light-emitting device packages, light-emitting device package strip, and light-emitting device package

ActiveUS20160057833A1Address rising pricesImprove productivityNon-electric lightingDischarge tube luminescnet screensPhosphorEngineering

Disclosed is a method for manufacturing a chip scale package (CSP) for a light-emitting diode (LED). The method may include a light-emitting device mounting step for mounting a plurality of light-emitting devices on a substrate strip, a phosphor forming step for forming a phosphor on the plurality of light-emitting devices, a reflective member forming step for forming a reflective member on the substrate strip to surround the phosphor, and a package singulation step for singulating unit packages by cutting the substrate strip and the reflective member.

Owner:LUMENS

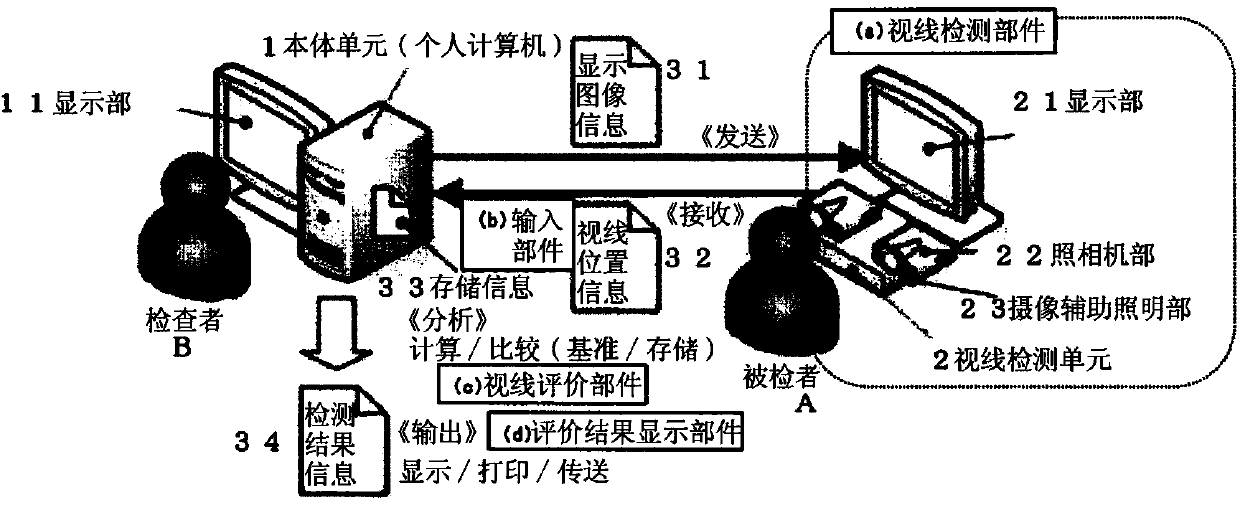

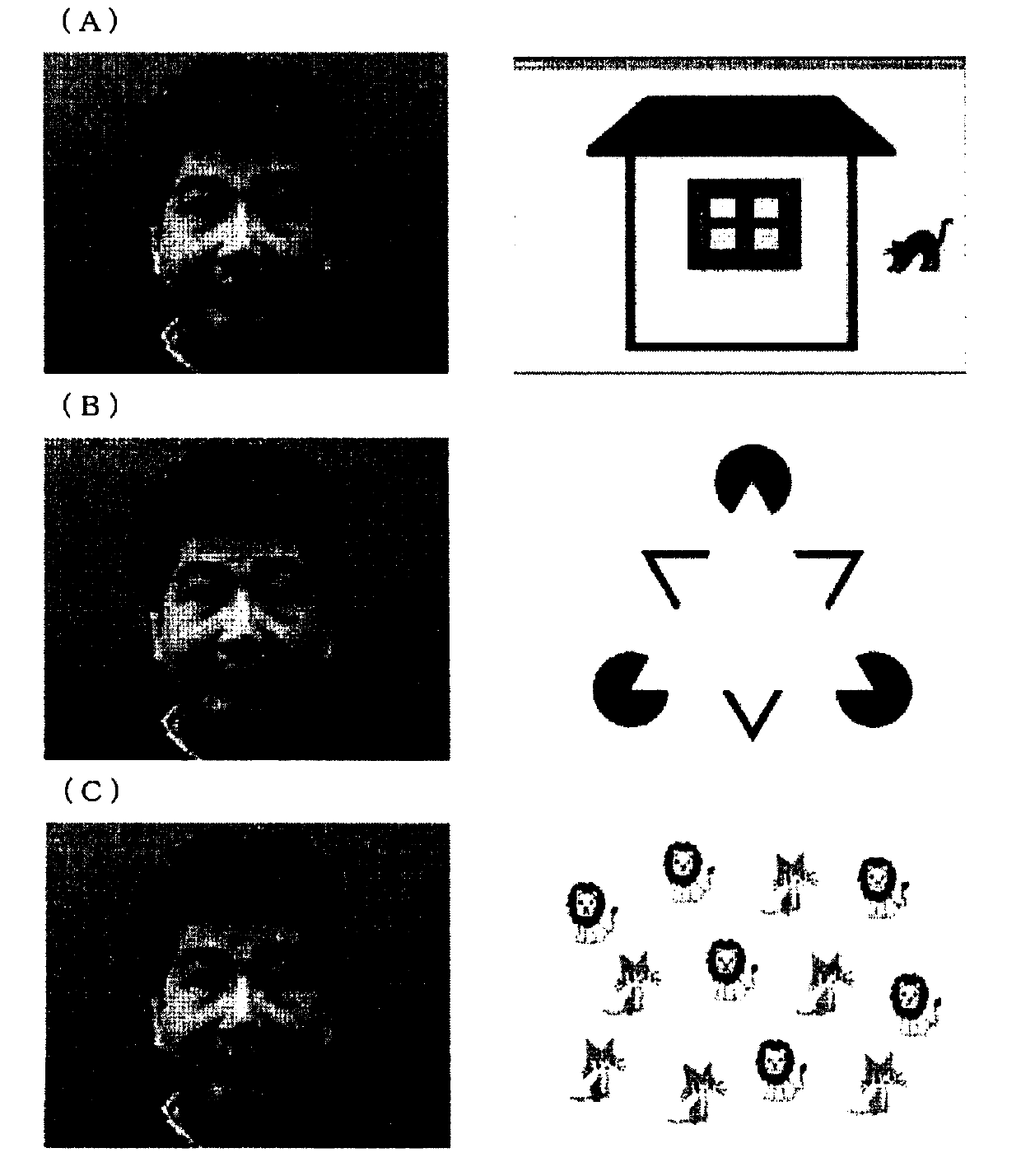

Asperger's diagnosis assistance method and system, and asperger's diagnosis assistance device

InactiveCN104219992AHelpful for evaluationEasy to seeSurgeryVaccination/ovulation diagnosticsClinical psychologyImage capture

Owner:HAMAMATSU UNIV SCHOOL OF MEDICINE

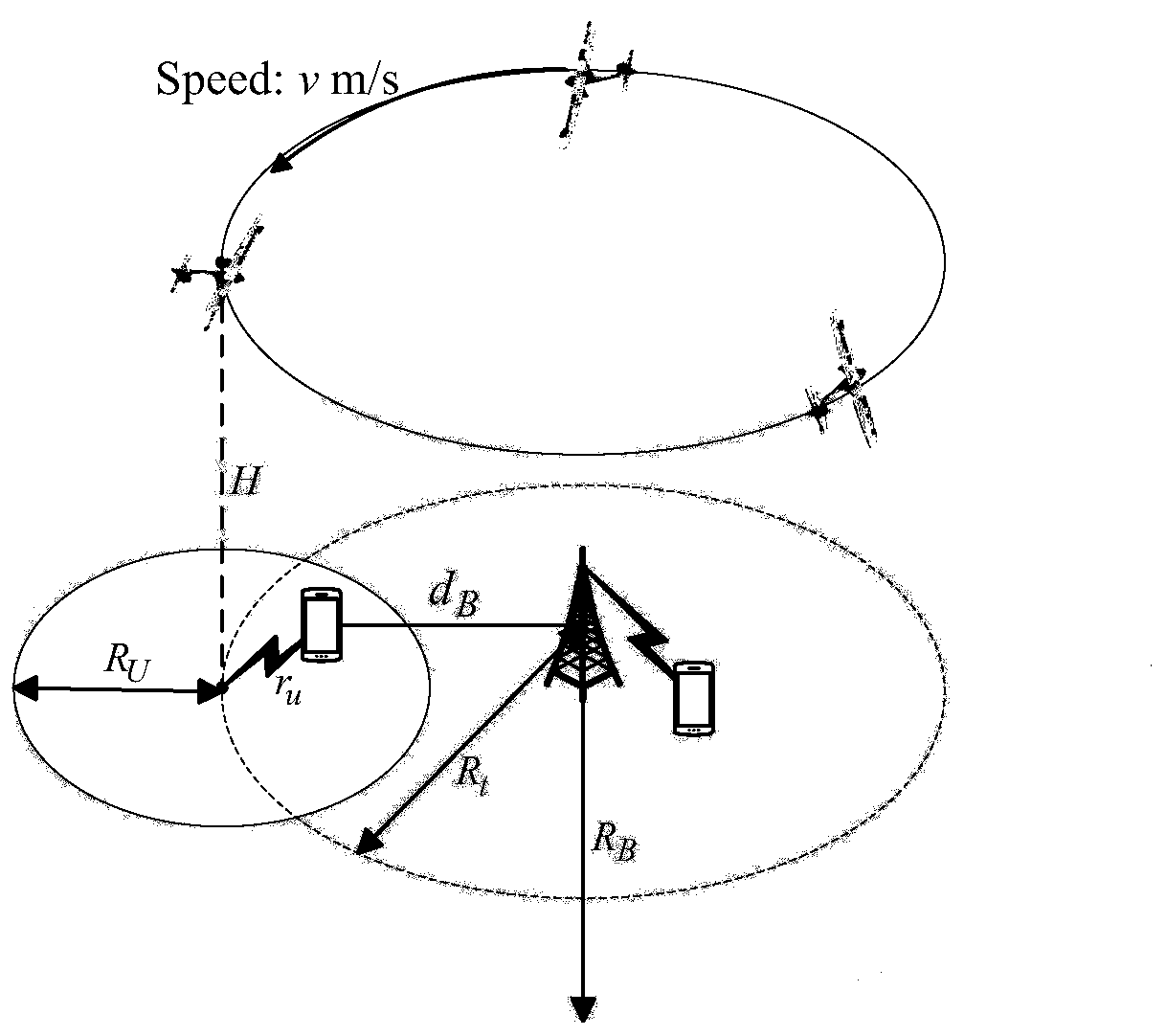

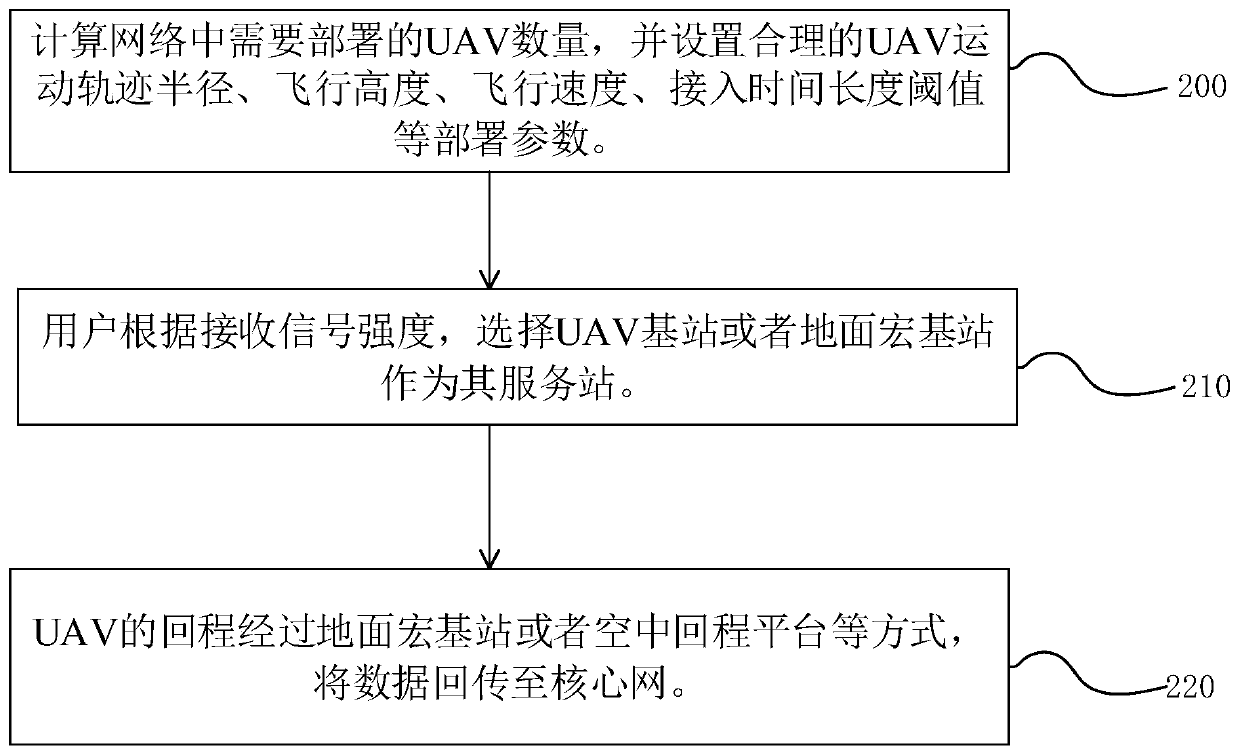

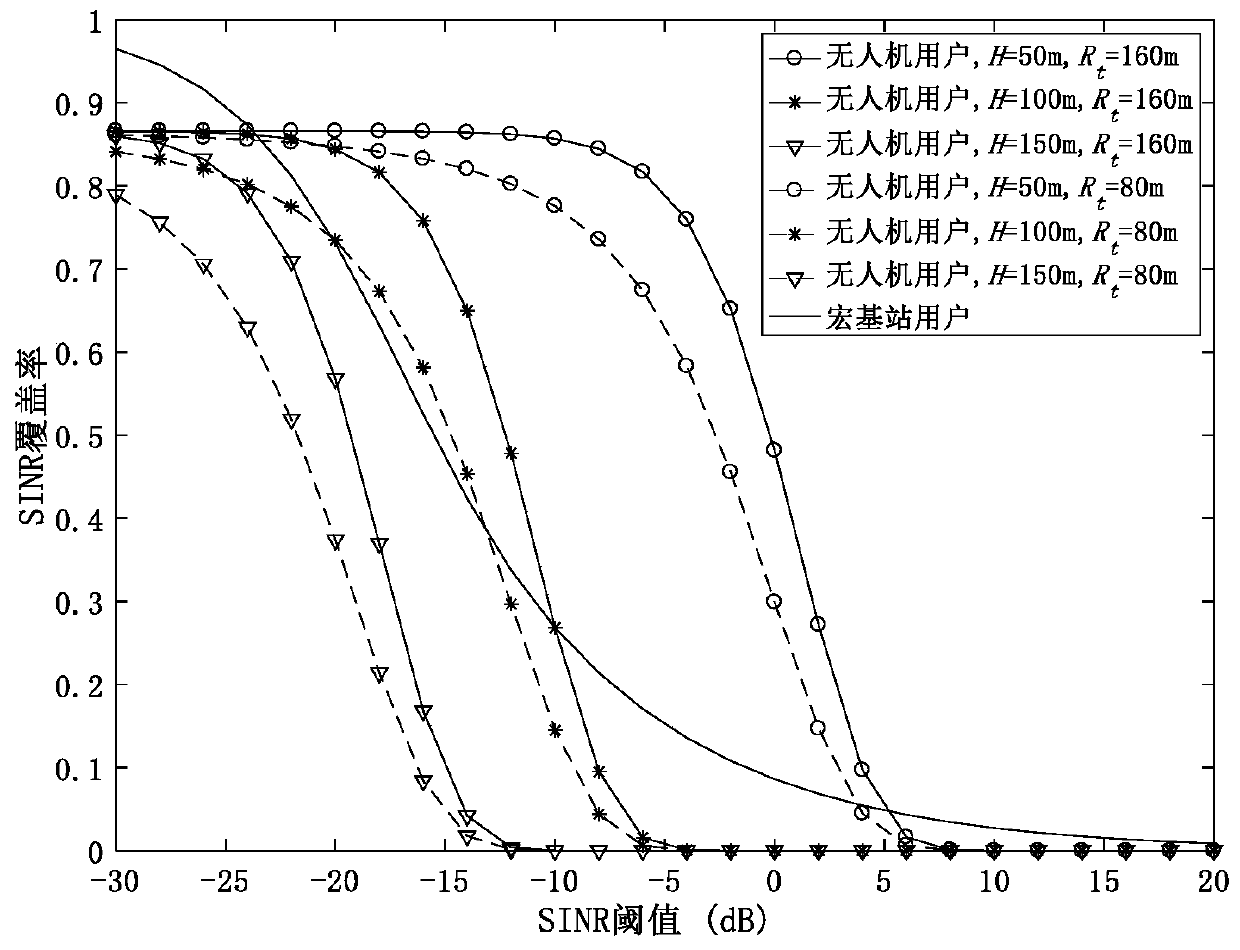

Macro station user distribution method for unmanned aerial vehicle auxiliary cellular network

ActiveCN110430550ARaise the level of performanceReduce performance varianceParticular environment based servicesRadio transmissionMacro base stationsTransmitted power

In order to solve the problems that a B5G / 6G network faces higher coverage and larger capacity requirements and an existing ground cellular network is difficult to guarantee the performance of edge users, the embodiment of the invention provides a macro station user distribution scheme for an unmanned aerial vehicle auxiliary cellular network, so that dynamic coverage is provided for the edge users. The method is beneficial to high channel gain brought by a large-probability line-of-sight link of an unmanned aerial vehicle base station; according to the scheme, one or more unmanned aerial vehicles take the ground macro base station as the center and do circular motion in the clockwise or anticlockwise direction, and a high data transmission rate is provided for macro cell users by utilizing the sight distance link and the antenna gain. By adjusting parameters such as the movement track radius, the flight height, the flight speed and the transmitting power of the unmanned aerial vehicle, the coverage range of the unmanned aerial vehicle is dynamically adjusted, and therefore network performance maximization is achieved.

Owner:BEIJING UNIV OF POSTS & TELECOMM

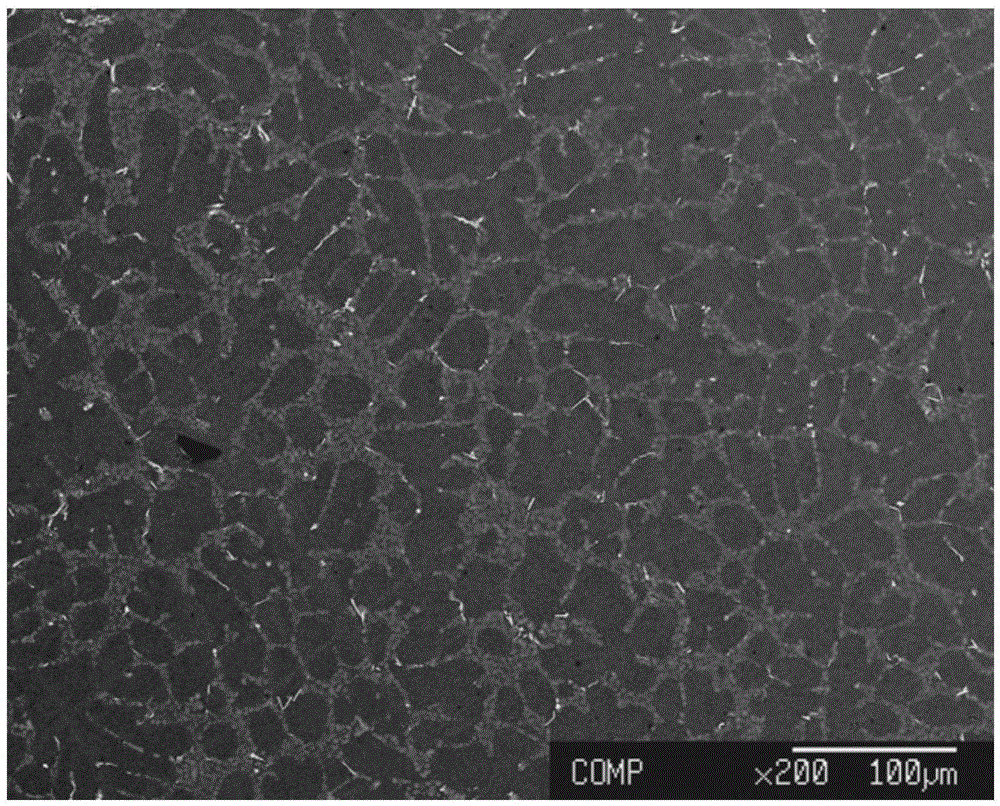

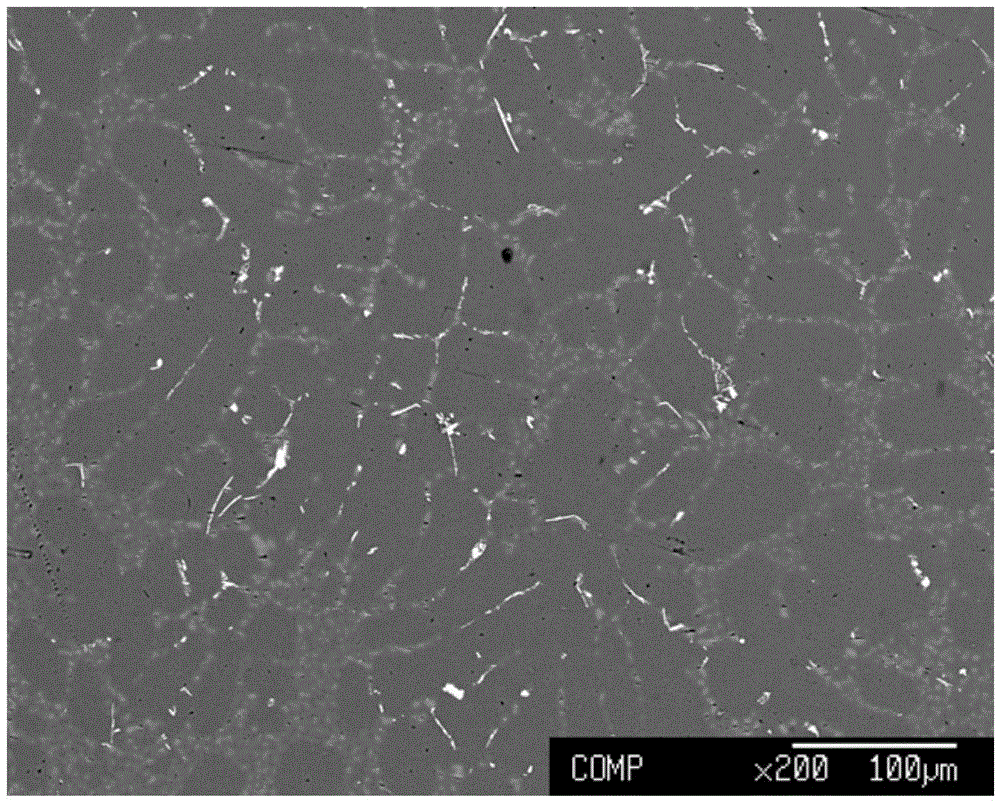

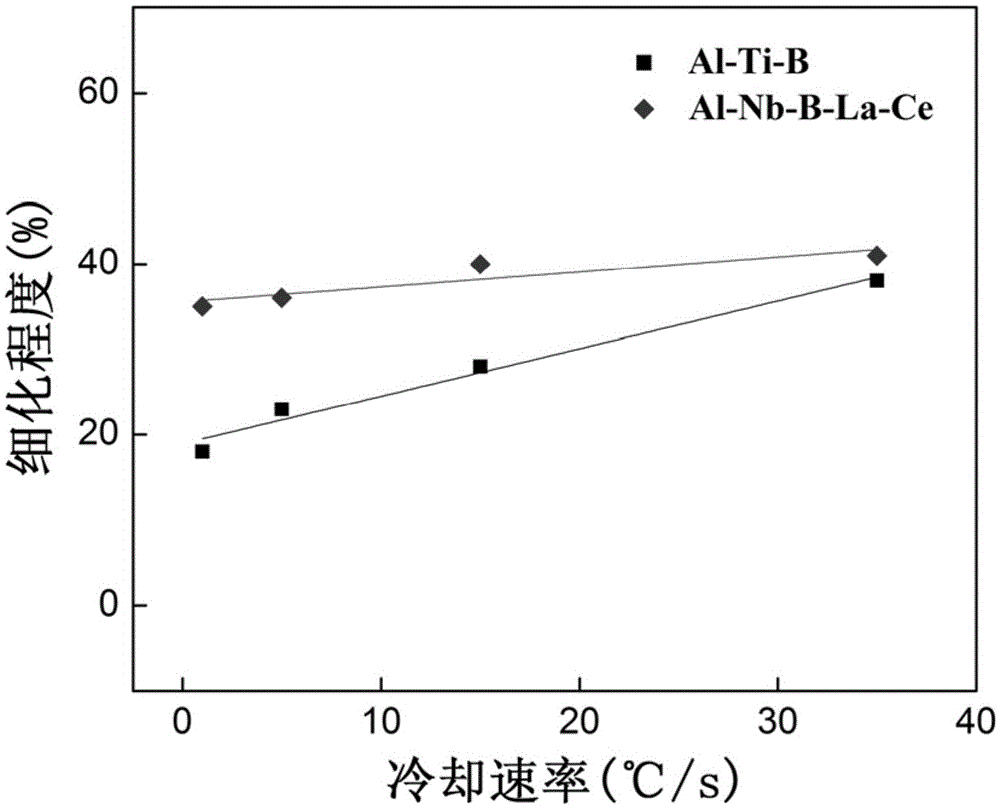

Low-cooling-rate sensitive high-nucleation-capacity AlNbTiBRE composite refining modifier used for aluminum alloy and preparation method of low-cooling-rate sensitive high-nucleation-capacity AlNbTiBRE composite refining modifier used for aluminum alloy

The invention discloses a low-cooling-rate sensitive high-nucleation-capacity AlNbTiBRE composite refining modifier used for aluminum alloy and a preparation method of the low-cooling-rate sensitive high-nucleation-capacity AlNbTiBRE composite refining modifier used for aluminum alloy. The low-cooling-rate sensitive high-nucleation-capacity AlNbTiBRE composite refining modifier is prepared from Al-xNb-yTi-zB-kRE, wherein 0.01<x<=6wt%, 0.01<y<=6wt%, 0.01<z<=1wt%, 0.01<k<=1wt%, and the balance is Al; and RE is one of La, Ce, Nd, Er, Gd, Y, Yb and Sc or a mixture of two or more of La, Ce, Nd, Er, Gd, Y, Yb and Sc. A preparation technology is simple, and the compositions can be precisely controlled. The composite refining modifier is used for processing aluminum alloy, and the refining effect and the modifying effect are excellent; for all parts of castings complex in shape and different in thickness, namely, all parts with different cooling rates, the cooling rate sensitivity of the refining effect is low; and the mechanical performance of the obtained alloy is remarkably improved, and the performance difference between the parts with different cooling rates is remarkably reduced.

Owner:北京航大新材科技有限公司

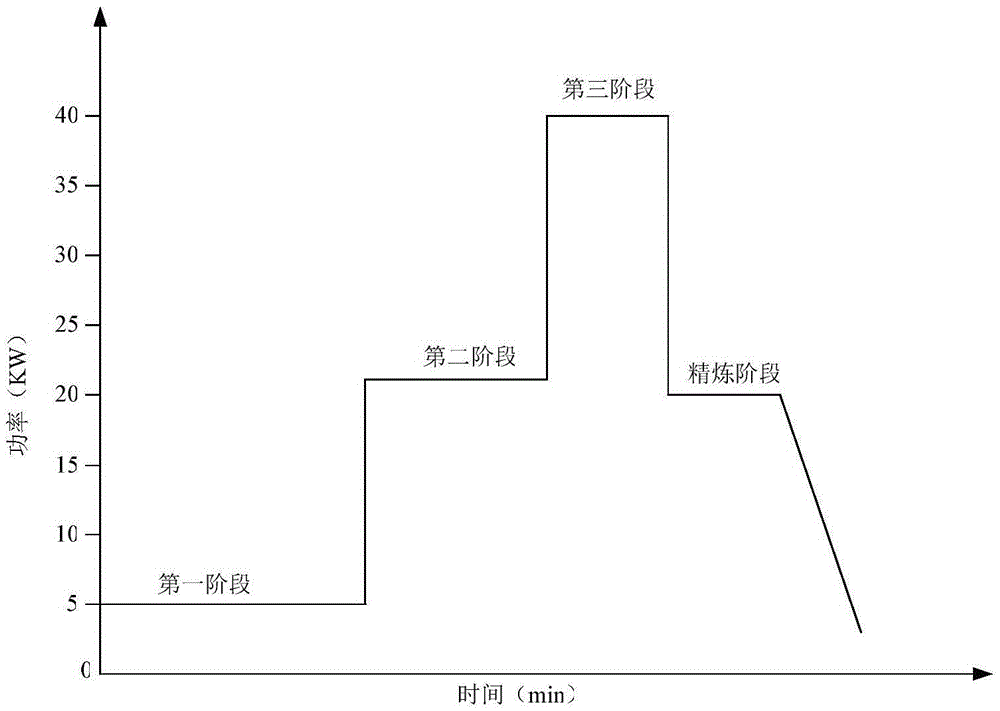

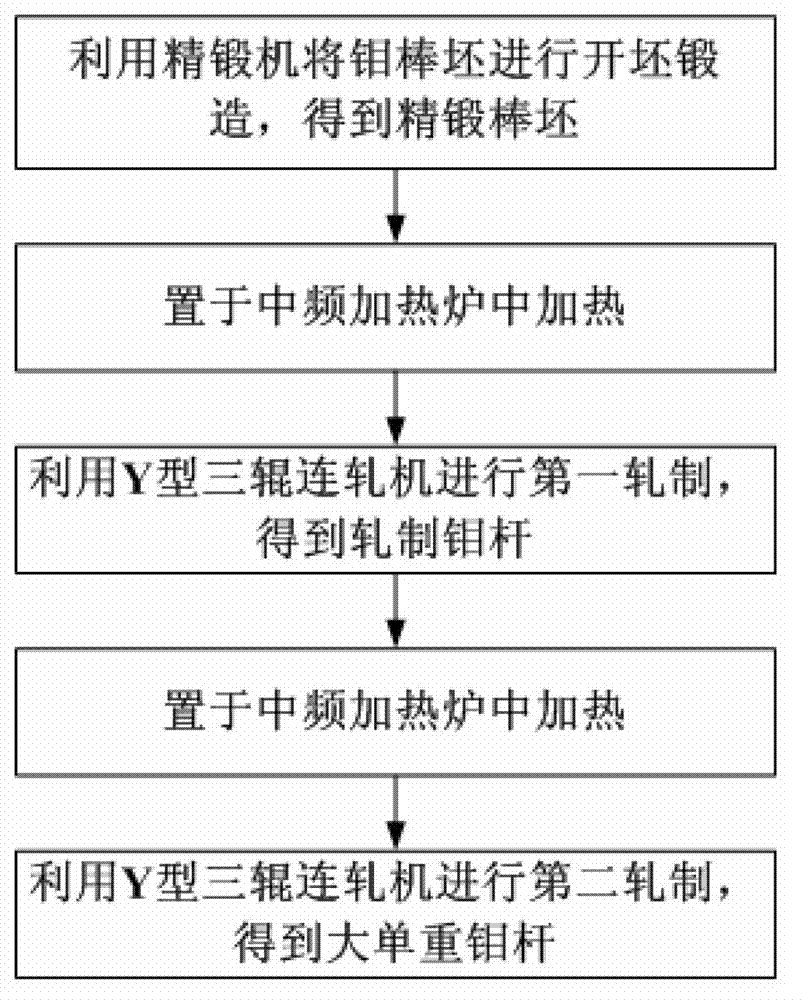

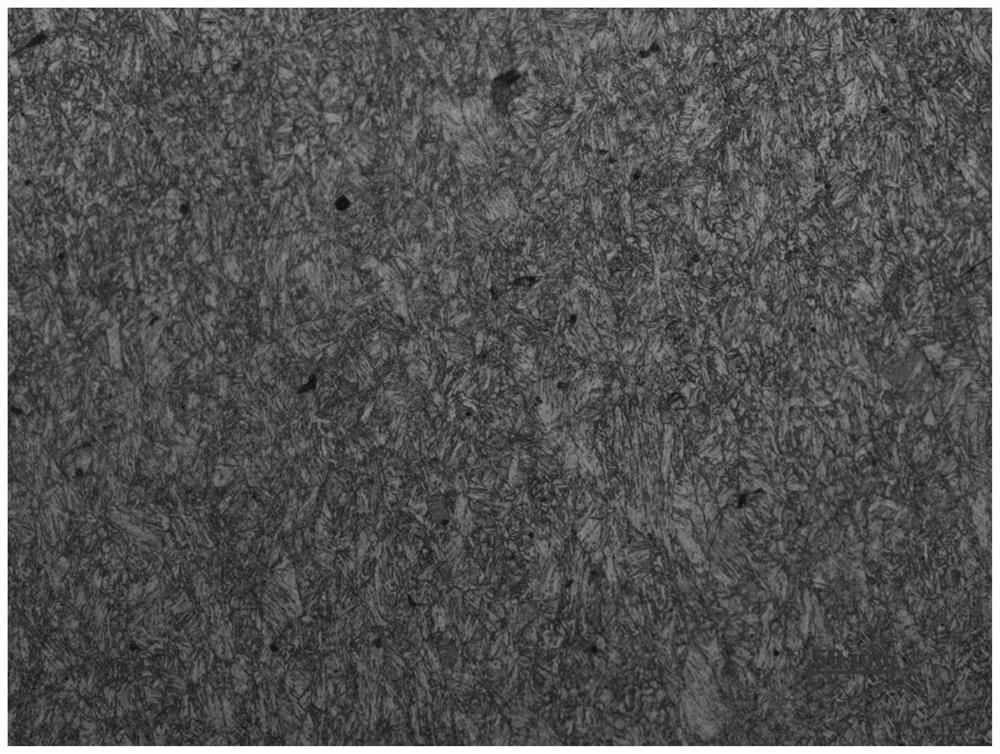

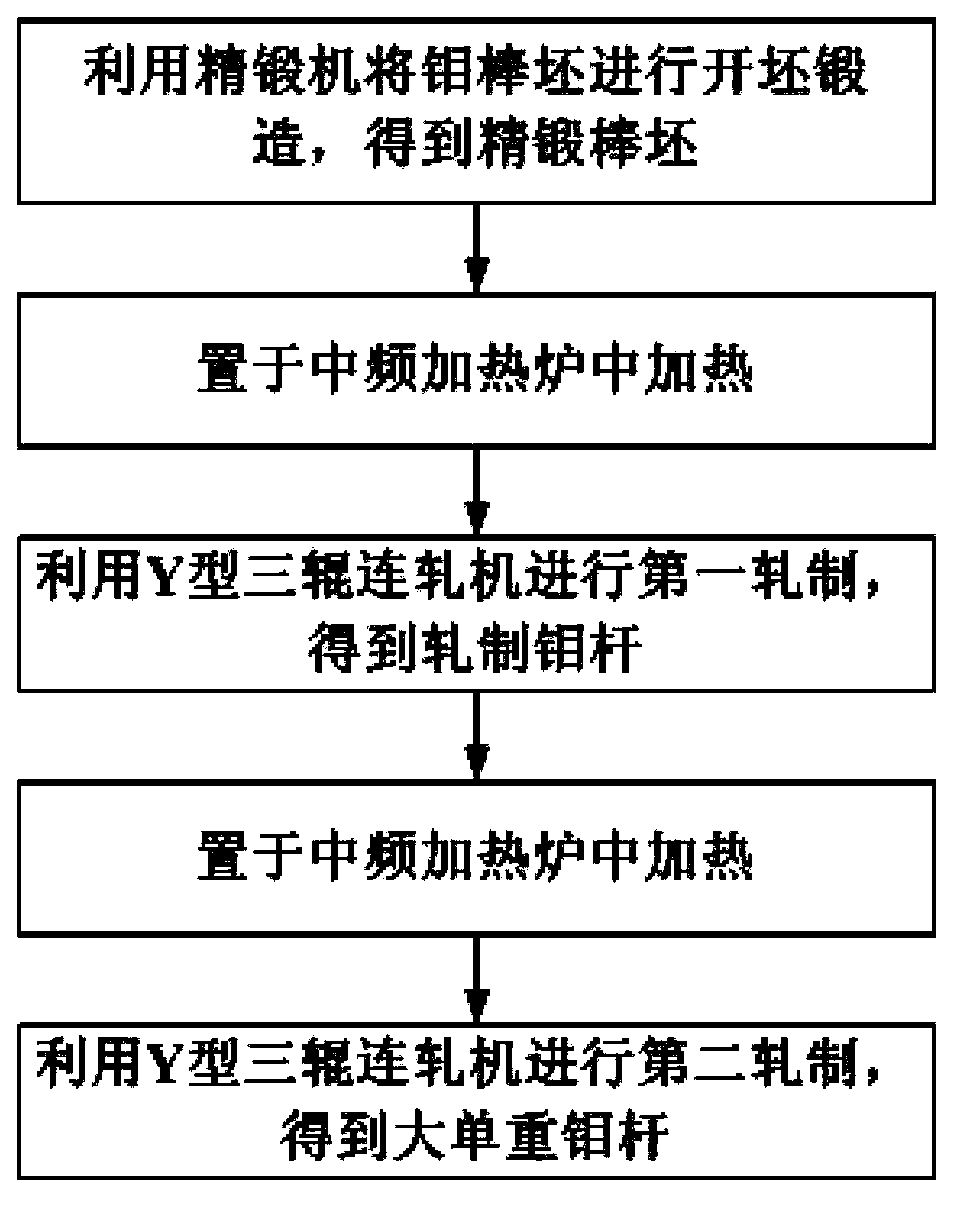

Precise forging-continuous rolling production technology of large and heavy single molybdenum rod

ActiveCN103042389ARealize deep processingIncrease productivityTemperature control deviceOther manufacturing equipments/toolsThermal treatmentContinuous rolling

The invention provides a precise forging-continuous rolling production technology of a large and heavy single molybdenum rod. The production technology comprises the following steps of: 1, carrying out billet forging on the molybdenum rod by a precision forging machine to obtain a precision forging bar; 2, heating the precision forging bar; 3, rolling for the first time by a Y-shaped three-roller continuous mill to obtain a rolled molybdenum rod; 4, heating the rolled molybdenum rod; and 5, rolling for the second time by the Y-shaped three-roller continuous mill and obtaining the large and heavy single molybdenum rod of which the piece weight is 45-50kg. Deep processing of a molybdenum bar is successfully achieved by setting and optimizing each parameter in precision forging, thermal treatment and continuous rolling processes; the large and heavy single molybdenum rod, which is suitable for subsequent wire drawing, and of which the piece weight is 45-50kg, is finally produced; and the production efficiency is obviously improved. The piece weight of the molybdenum rod produced by the production technology is much greater than that of the molybdenum rod produced by a traditional technology; and the precise forging-continuous rolling production technology has no welding spot on the whole, and is even in internal organization, high in product quality and suitable for large-scale industrial production.

Owner:JINDUICHENG MOLYBDENUM CO LTD

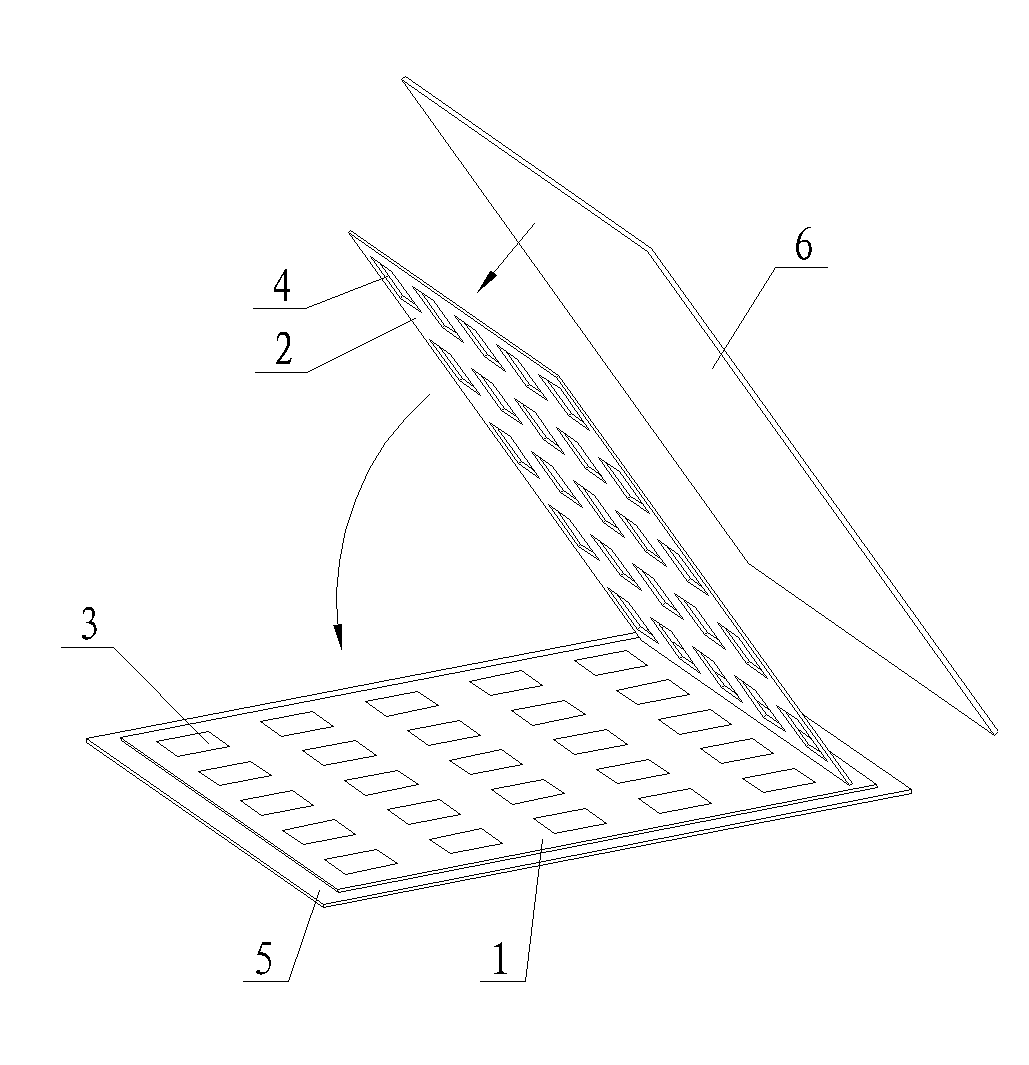

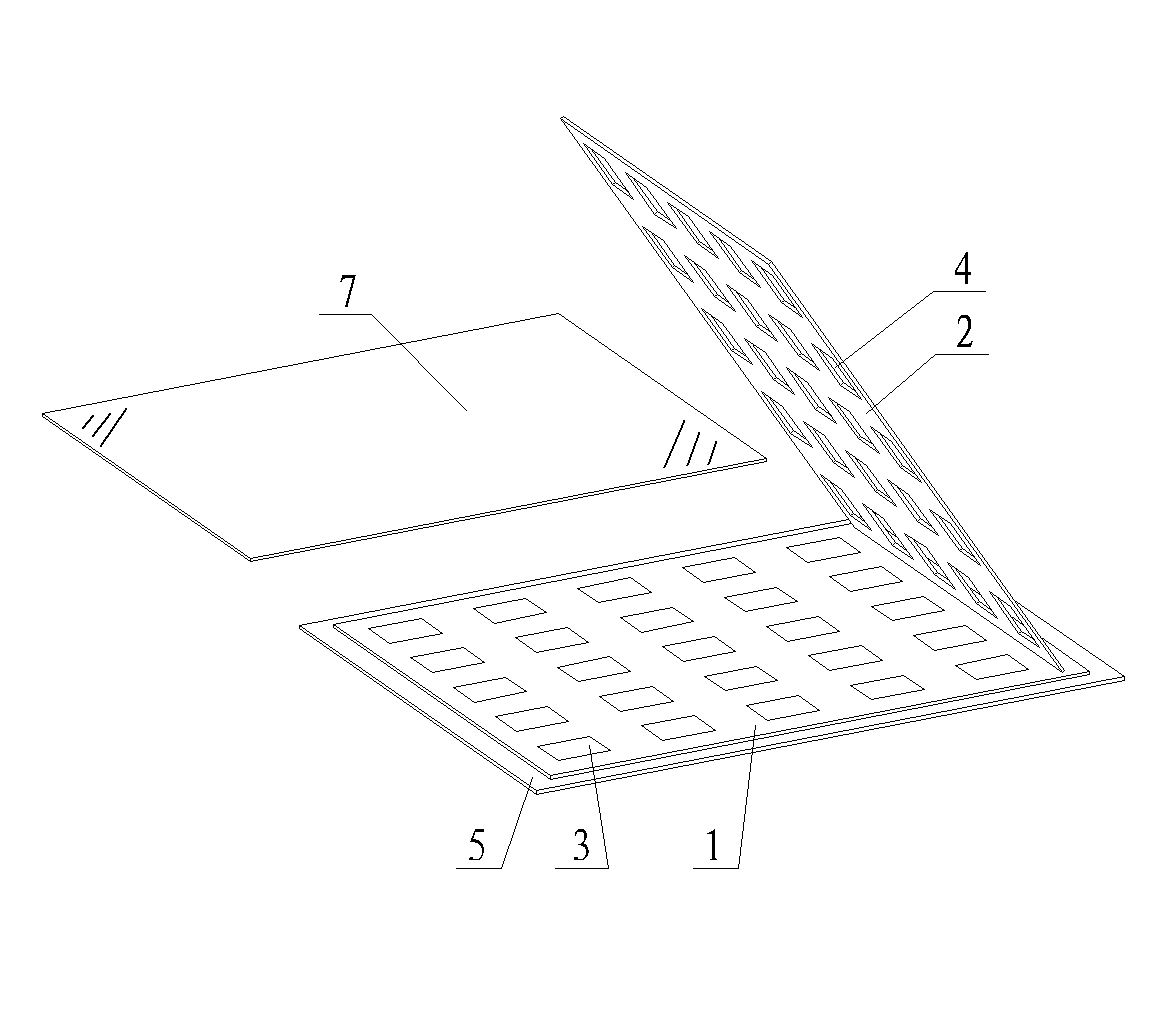

Batch production method of membrane electrode and manufacturing mould therefor

The invention provides a batch production method of a membrane electrode, which can carry out batch production. The batch production method is characterized by comprising the following steps: (1) preparing an anode gas diffusion layer and a cathode gas diffusion layer which are of the same area; (2) coating a catalytic layer to form an anode gas diffusion electrode and a cathode gas diffusion electrode; (3) clipping the anode gas diffusion electrode and the cathode gas diffusion electrode into small pieces of gas diffusion electrodes of the same dimension and quantity; (4) respectively placing the small pieces of anode gas diffusion electrodes and the small pieces of cathode gas diffusion electrodes in upper ledge openings and lower ledge openings of a hot-pressing mould frame and tiling a proton exchange membrane between the upper edges and the lower edges; (5) placing the whole hot-pressing mould into a hot press to prepare a conjoined membrane electrode structure; and (6) separating the conjoined membrane electrode structure from the middle position of the proton exchange membrane of an adjacent single membrane electrode.

Owner:江西德合医疗器械有限公司

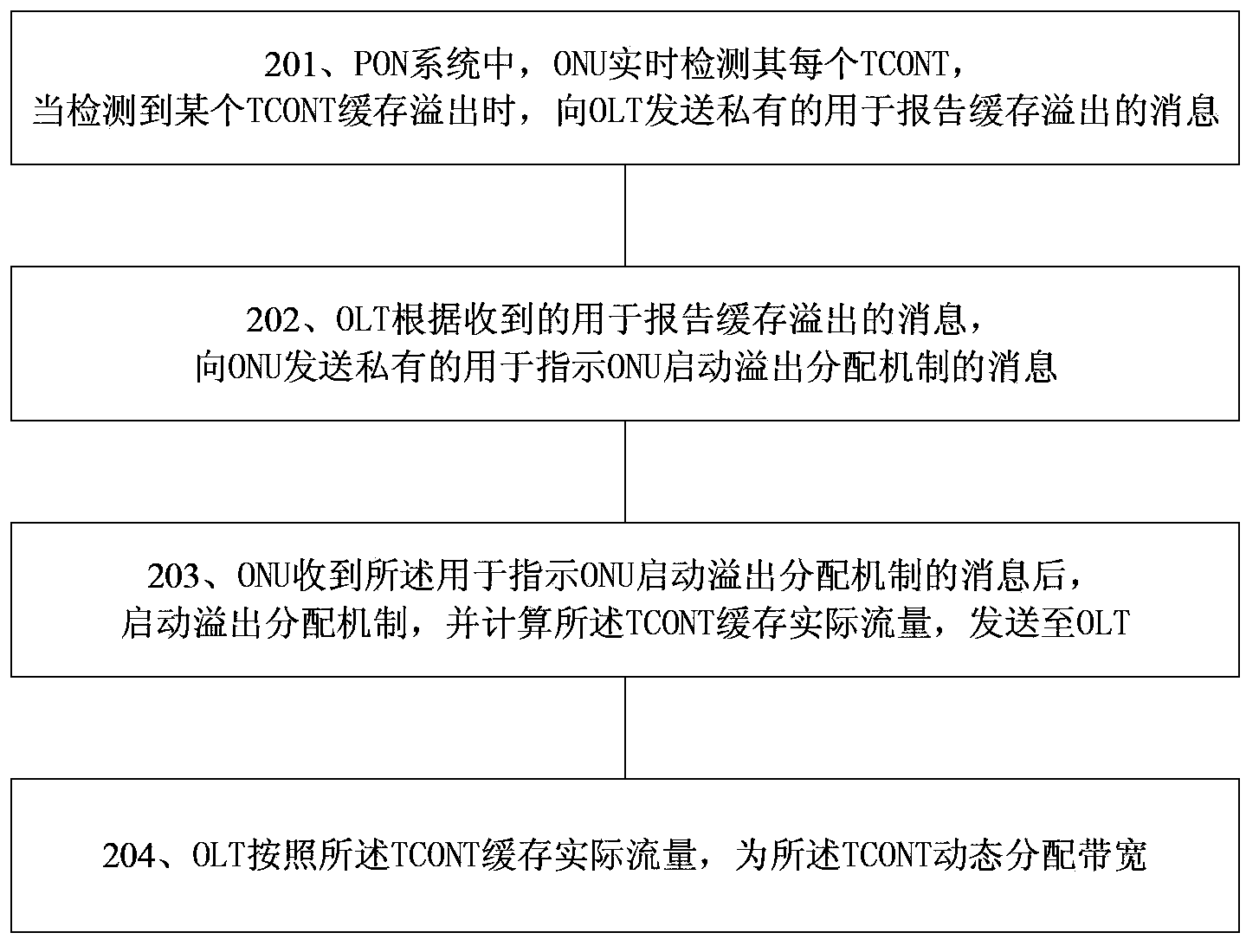

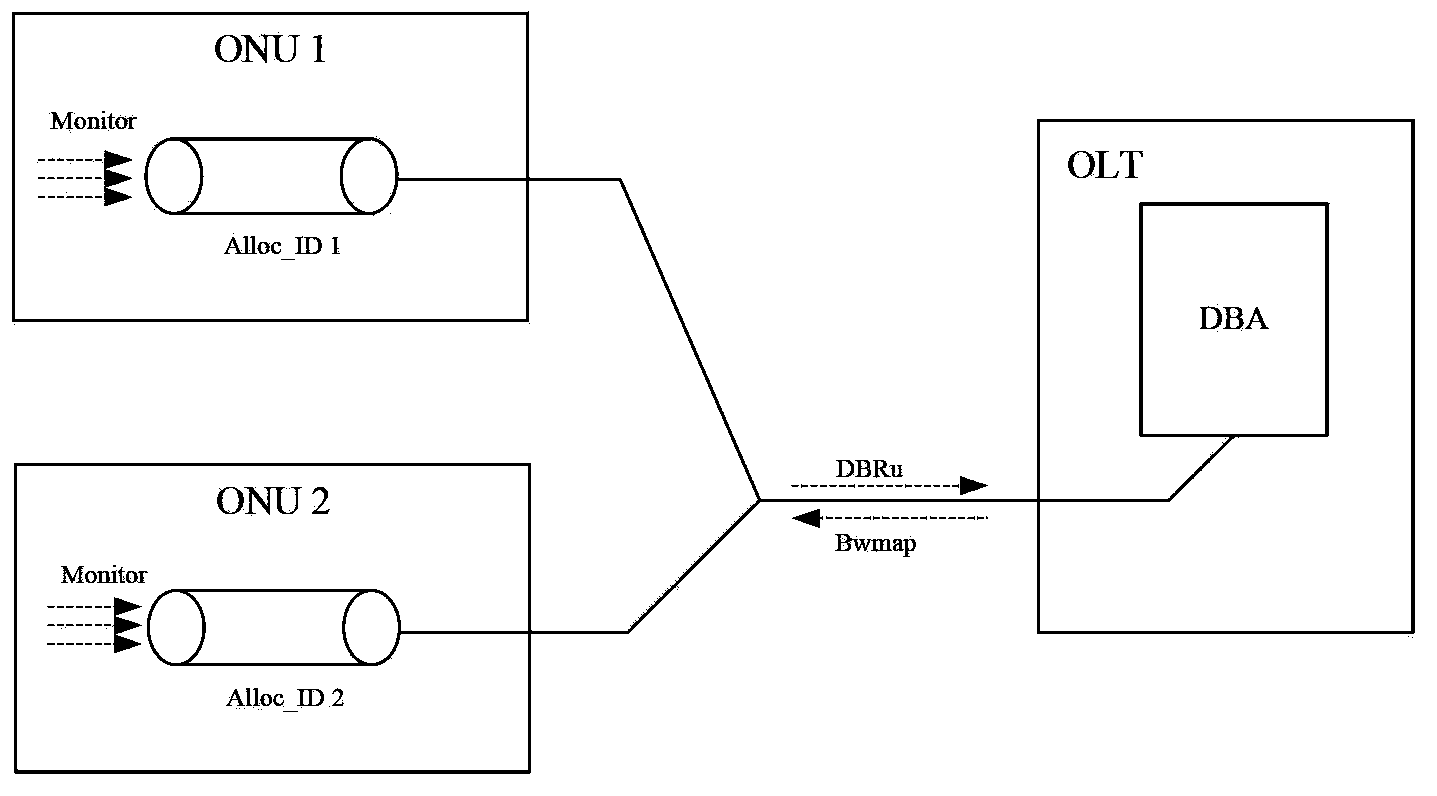

Method and system for improving bandwidth allocation efficiency

InactiveCN104053076AImprove distribution efficiencyReduce performance varianceMultiplex system selection arrangementsHybrid transportOptical communicationOptical network unit

The invention, which relates to the field of optical communication, discloses a method and system for improving a bandwidth allocation efficiency. The method comprises: in a passive optical network (PON) system, an optical network unit (ONU) detects each transmission container TCONT in real time; when one certain TCONT is detected to be buffered and overflowed, a private message for reporting buffering and overflowing is sent to an optical line terminal (OLT); according to the message for reporting buffering and overflowing, the OLT sends a private message for indicating the ONU to start an overflowing allocation mechanism to the ONU; after the ONU receives the message for indicating the ONU to start the overflowing allocation mechanism, the overflow allocation mechanism is started and an actual buffer flow of the TCONT is calculated, and the calculated actual flow is sent to the OLT; and on the basis of the actual buffer flow of the TCONT, the OLT allocates the bandwidth to the TCONT dynamically.

Owner:ZTE CORP +1

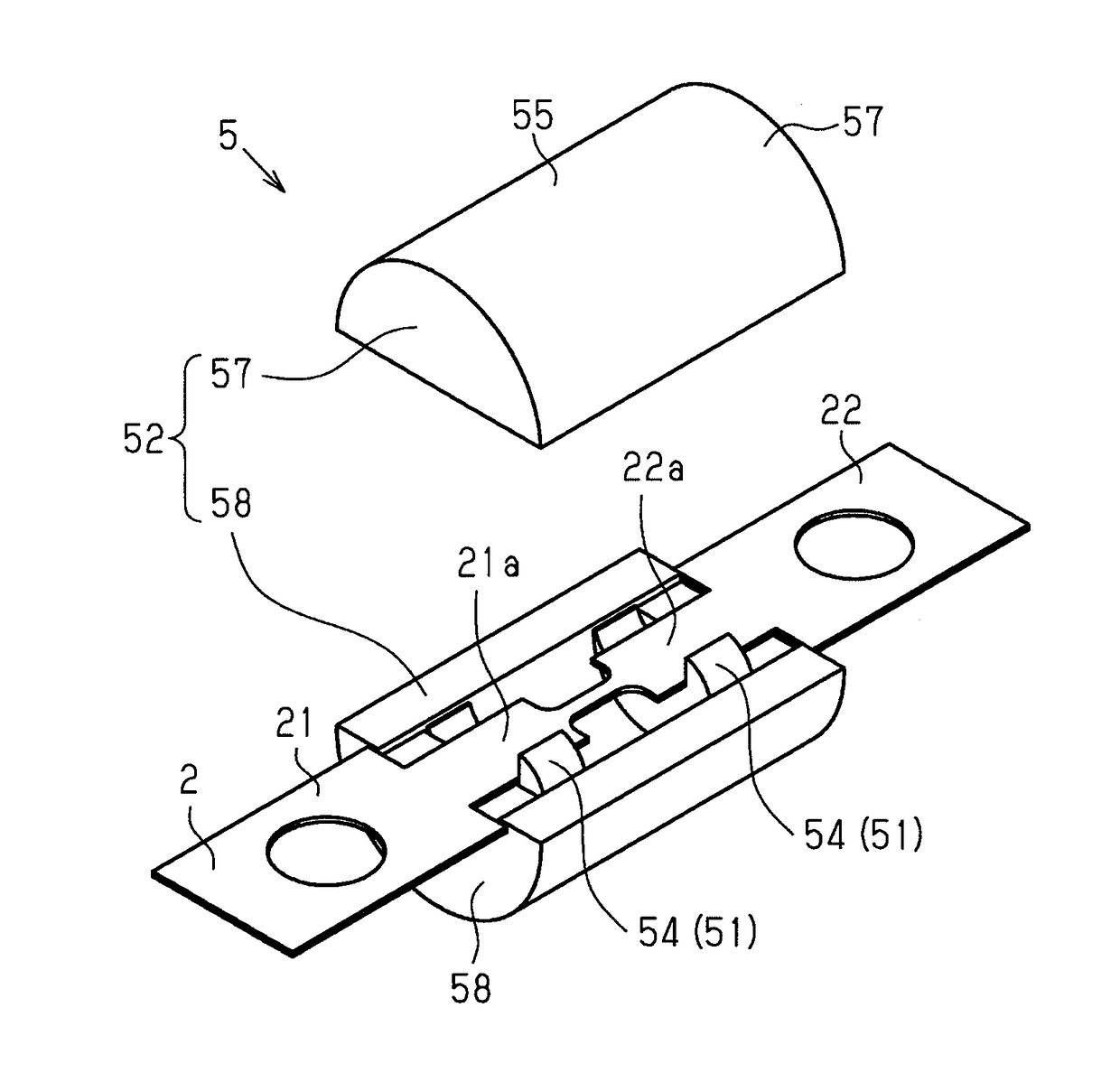

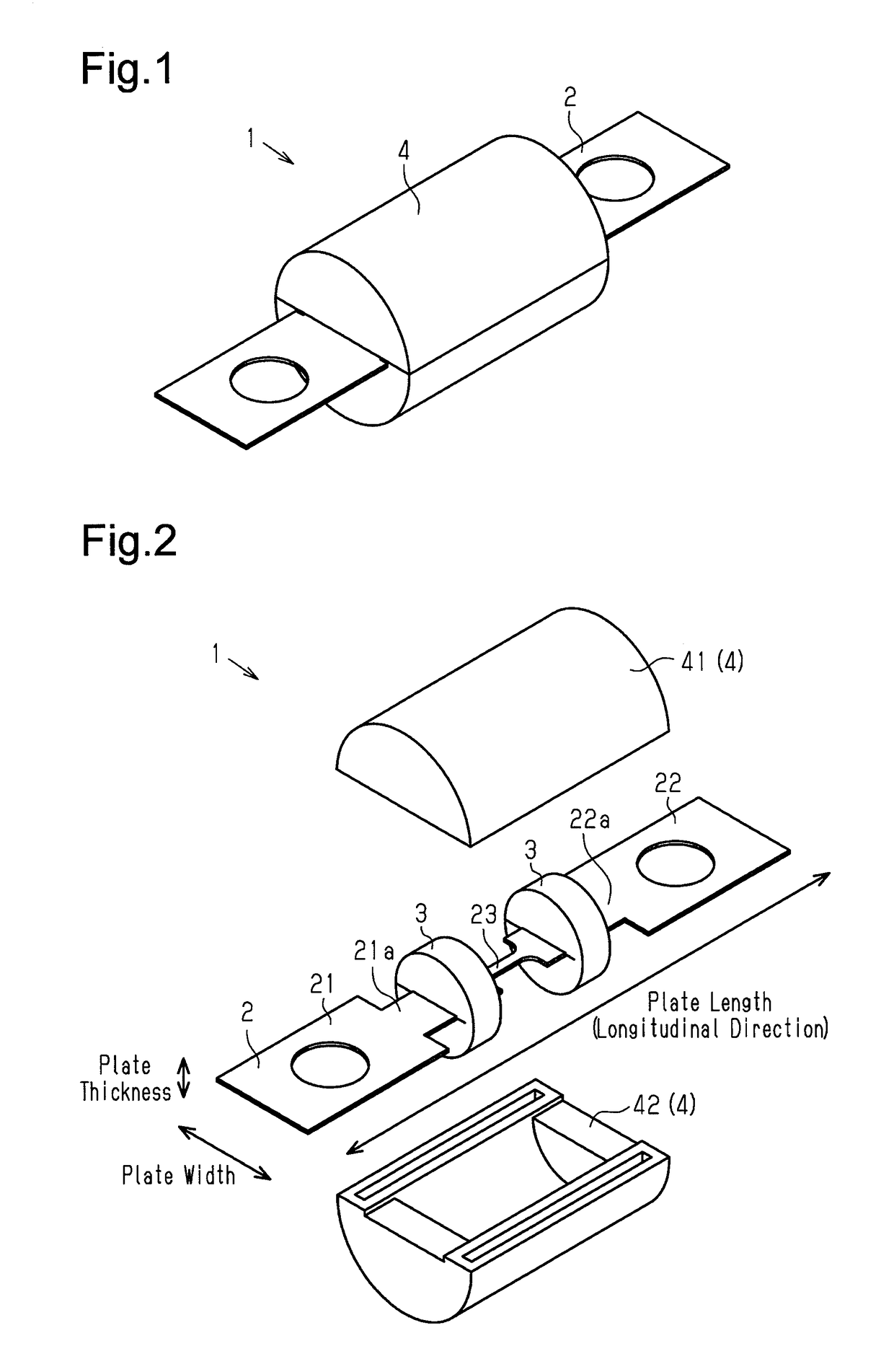

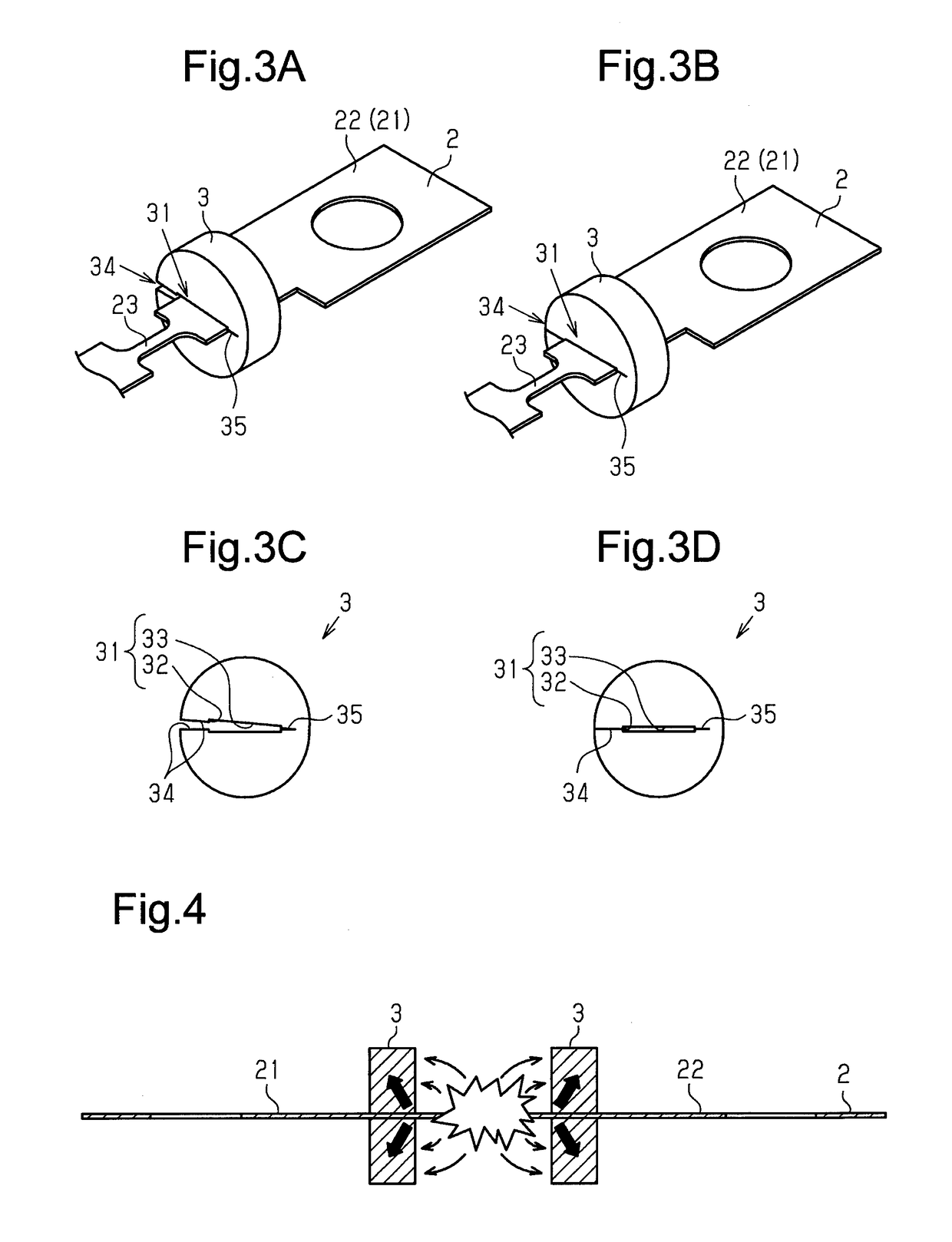

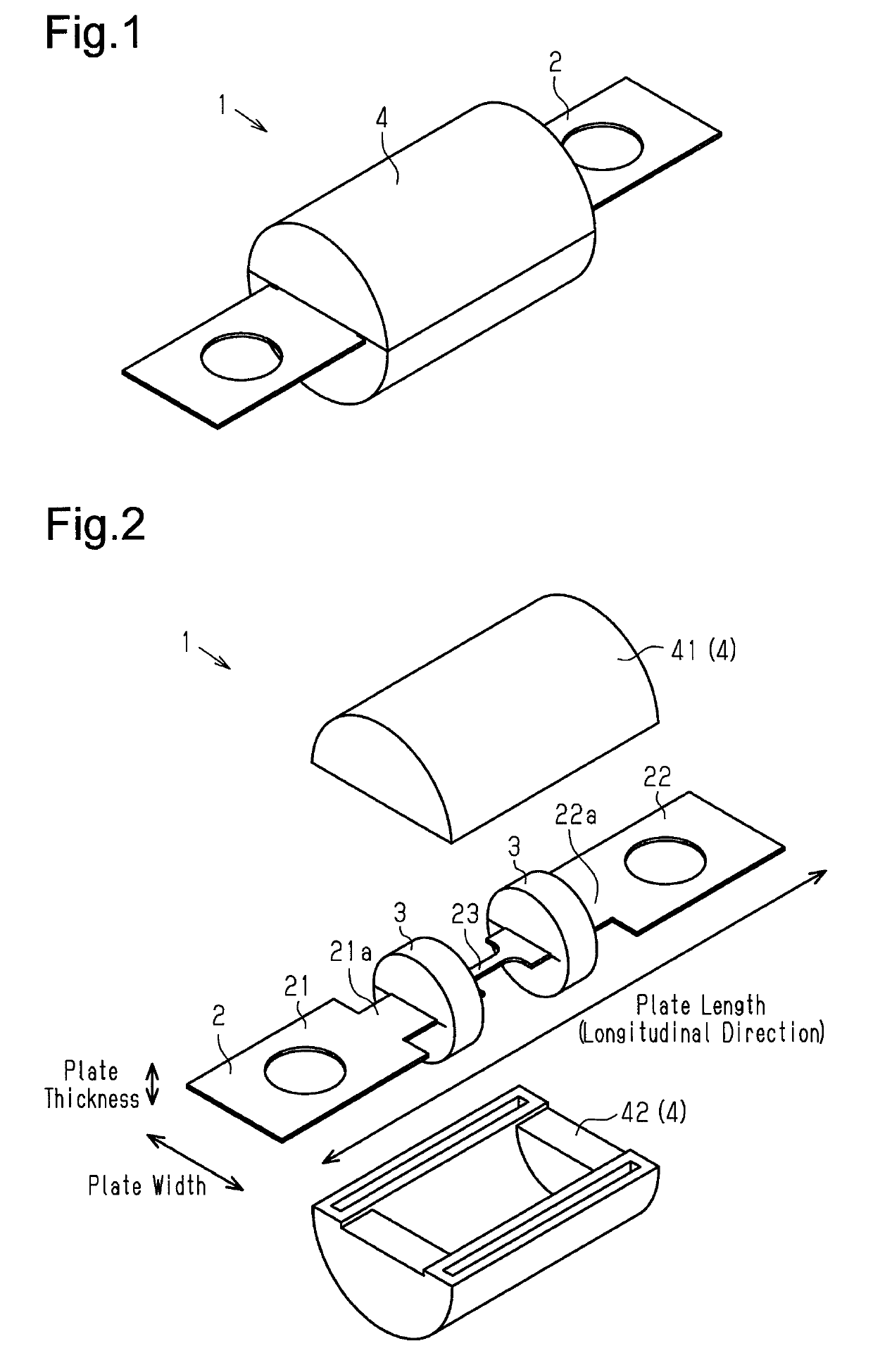

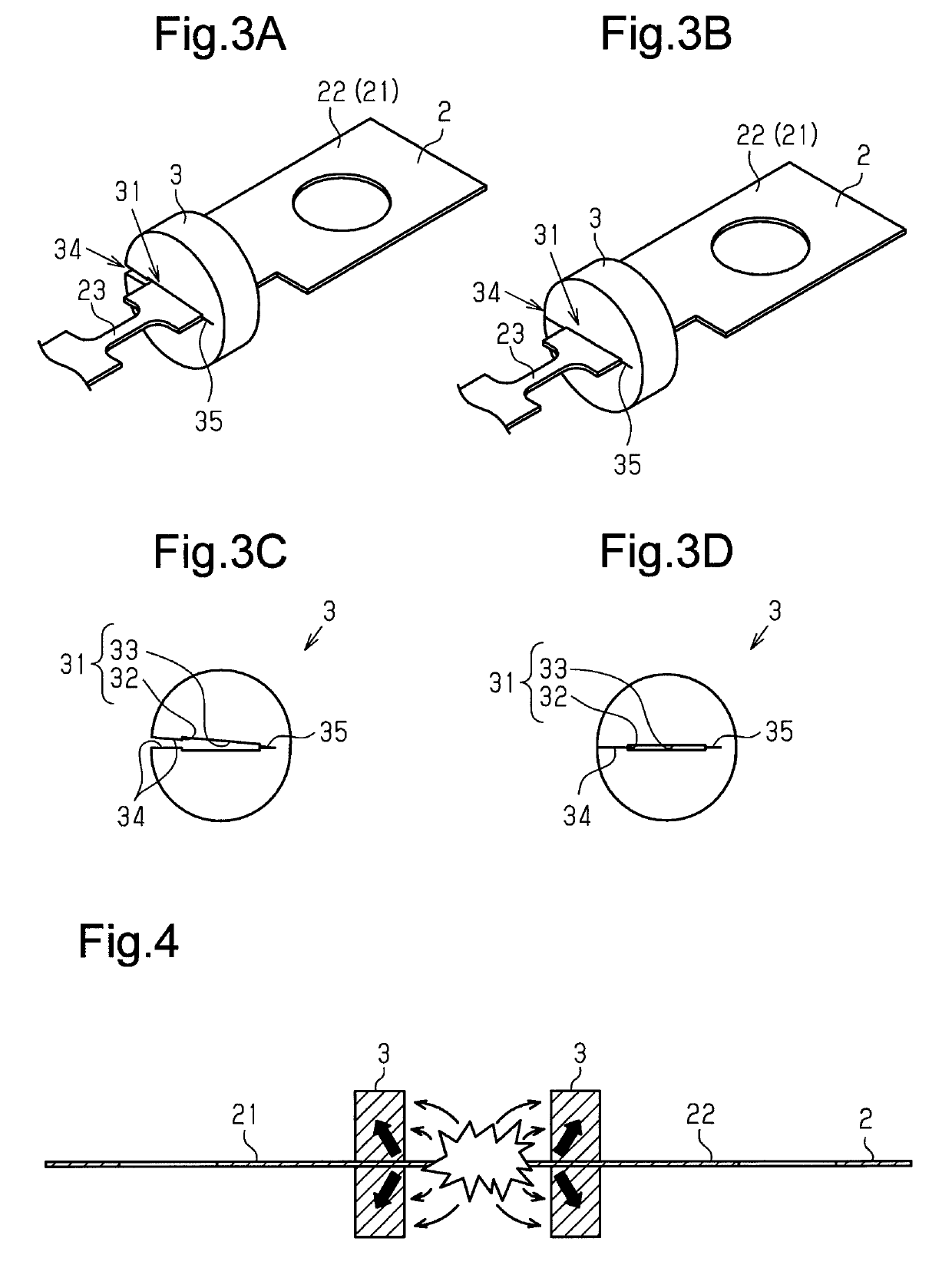

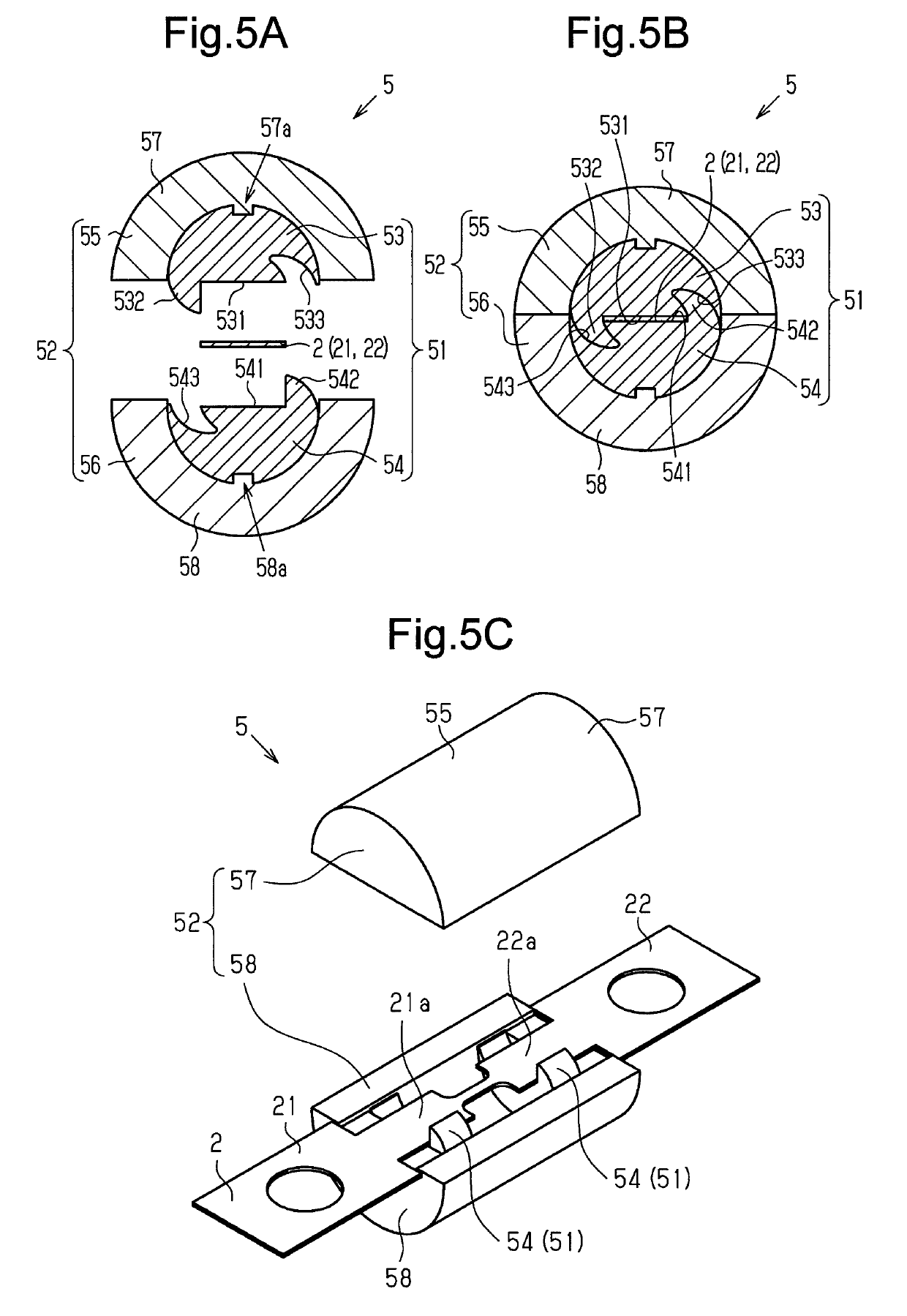

Fuse

ActiveUS20180174791A1Reduce performance varianceEasy to manufactureEmergency protective devicesEngineeringElectrical and Electronics engineering

A fuse includes a conductive member formed integrally with a melting portion that melts and breaks when overcurrent occurs, two shielding portions arranged on the conductive member to hold the melting portion in between, and a case formed from an electrically-insulative material. The case encloses the melting portion in cooperation with the two shielding portions.

Owner:TOYODA IRON WORKS CO LTD

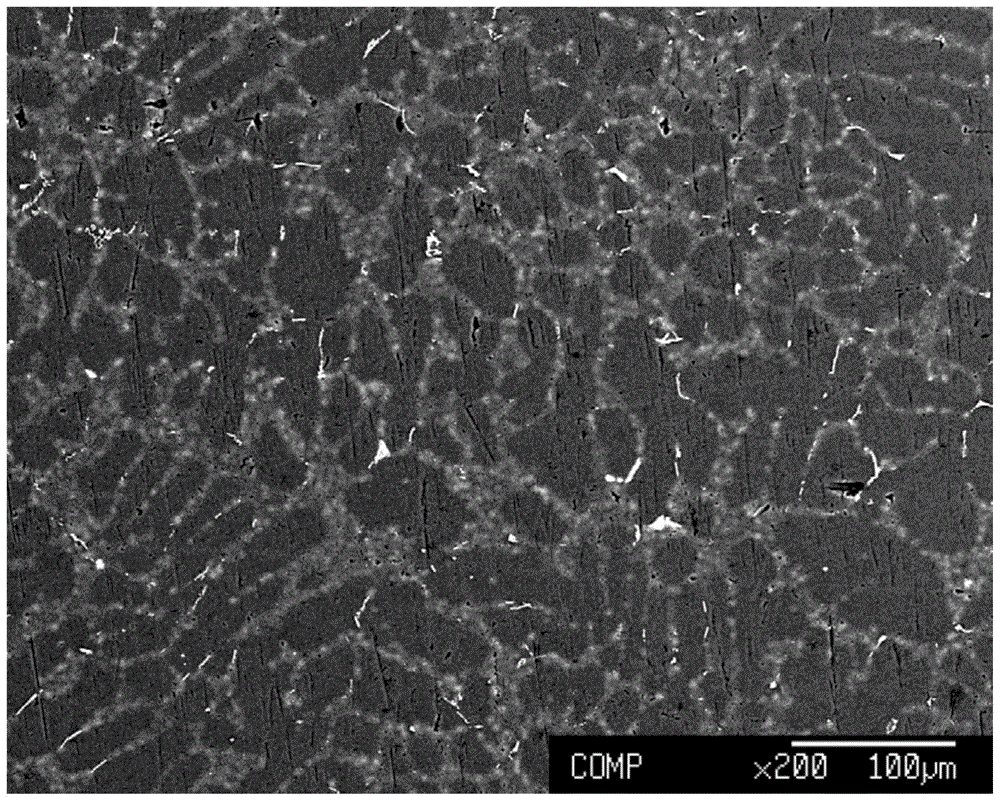

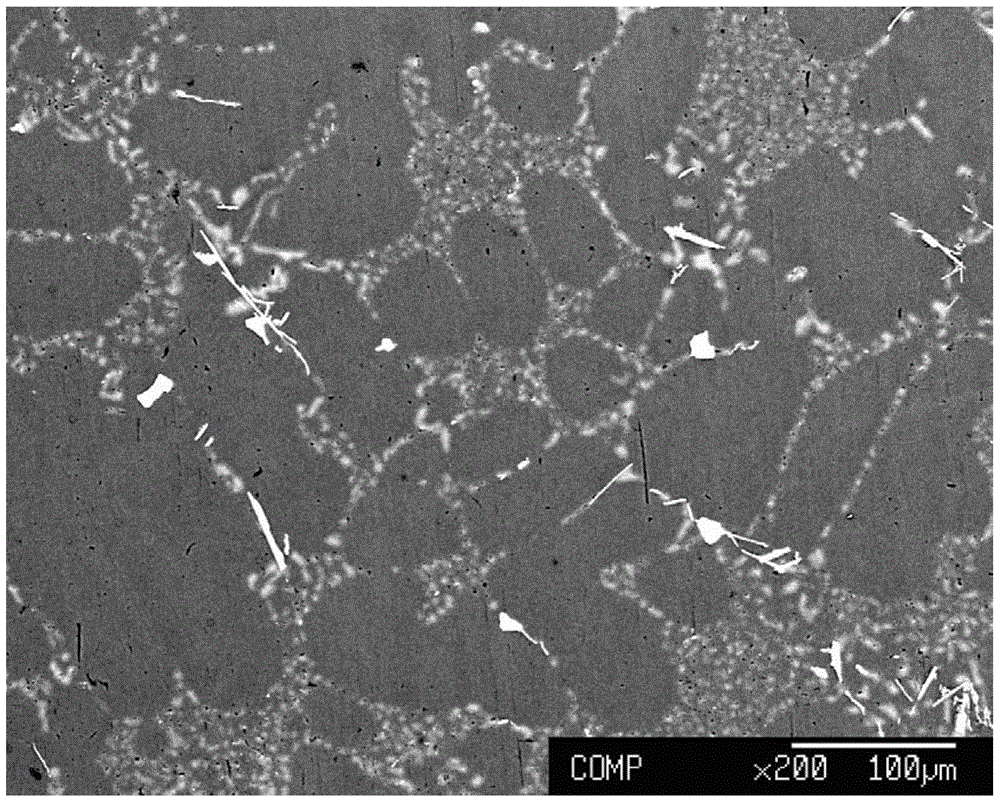

Low-cooling-rate-sensitivity high-nucleation-ability AlNbBRE grain refiner for cast aluminum alloy and preparation method thereof

The invention discloses a low-cooling-rate-sensitivity high-nucleation-ability grain refiner for cast aluminum alloy and a preparation method thereof. The grain refiner comprises Al-xNb-yB-zRE, wherein x is higher than 0.01wt% and not higher than 6wt%, y is higher than 0.01wt% and not higher than 3wt%, z is higher than 0.01wt% and not higher than 1wt%, and the balance Al; RE is one or more of La, Ce, Nd, Er, Gd, Y, Yb and Sc. Meanwhile, the invention discloses the smelting method for preparing the grain refiner, and the preparation technological process is simple. The grain refiner is used for carrying out grain refining on the cast aluminum-silicon alloy, the refining effect is superior, the cooling-rate sensitivity on the refining effects of casting portions in complex shapes and different thicknesses, namely the portions with different cooling rates is low, the mechanical performance of the refined alloy is remarkably improved, and the difference of performance between the portions with the different cooling rates is remarkably lowered.

Owner:BEIHANG UNIV

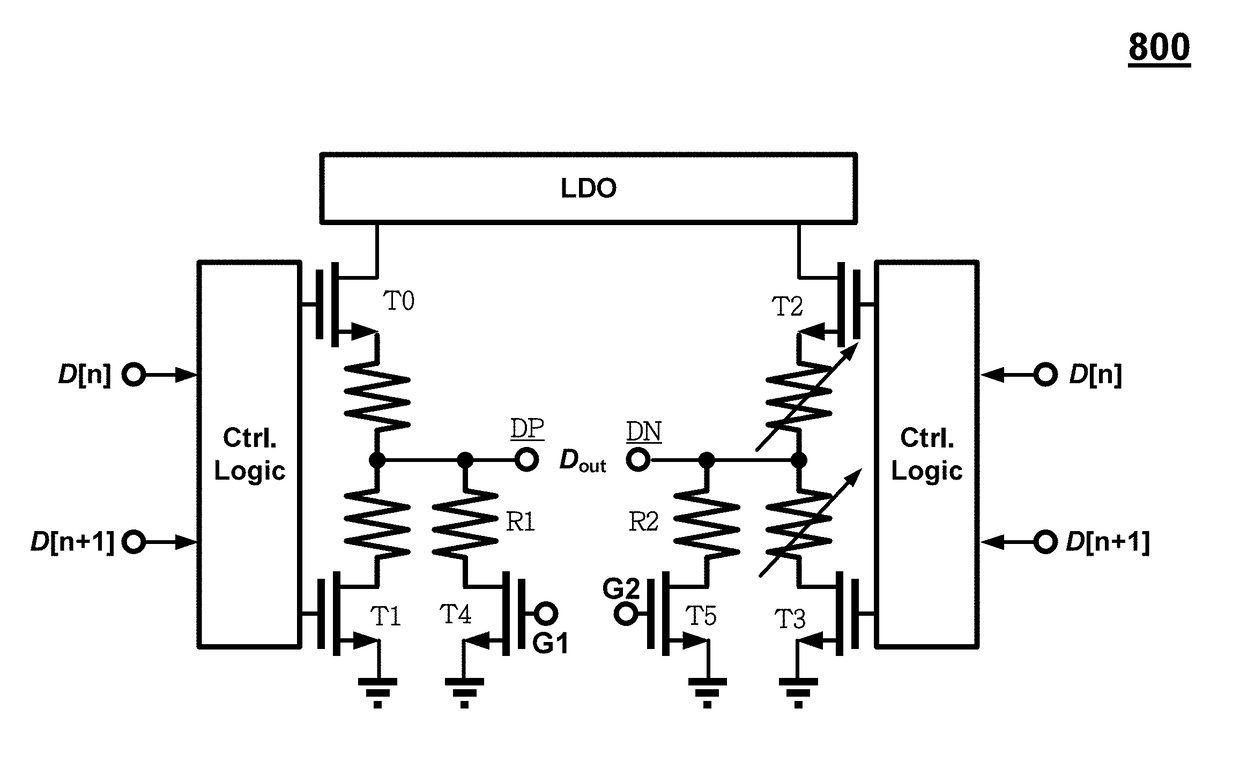

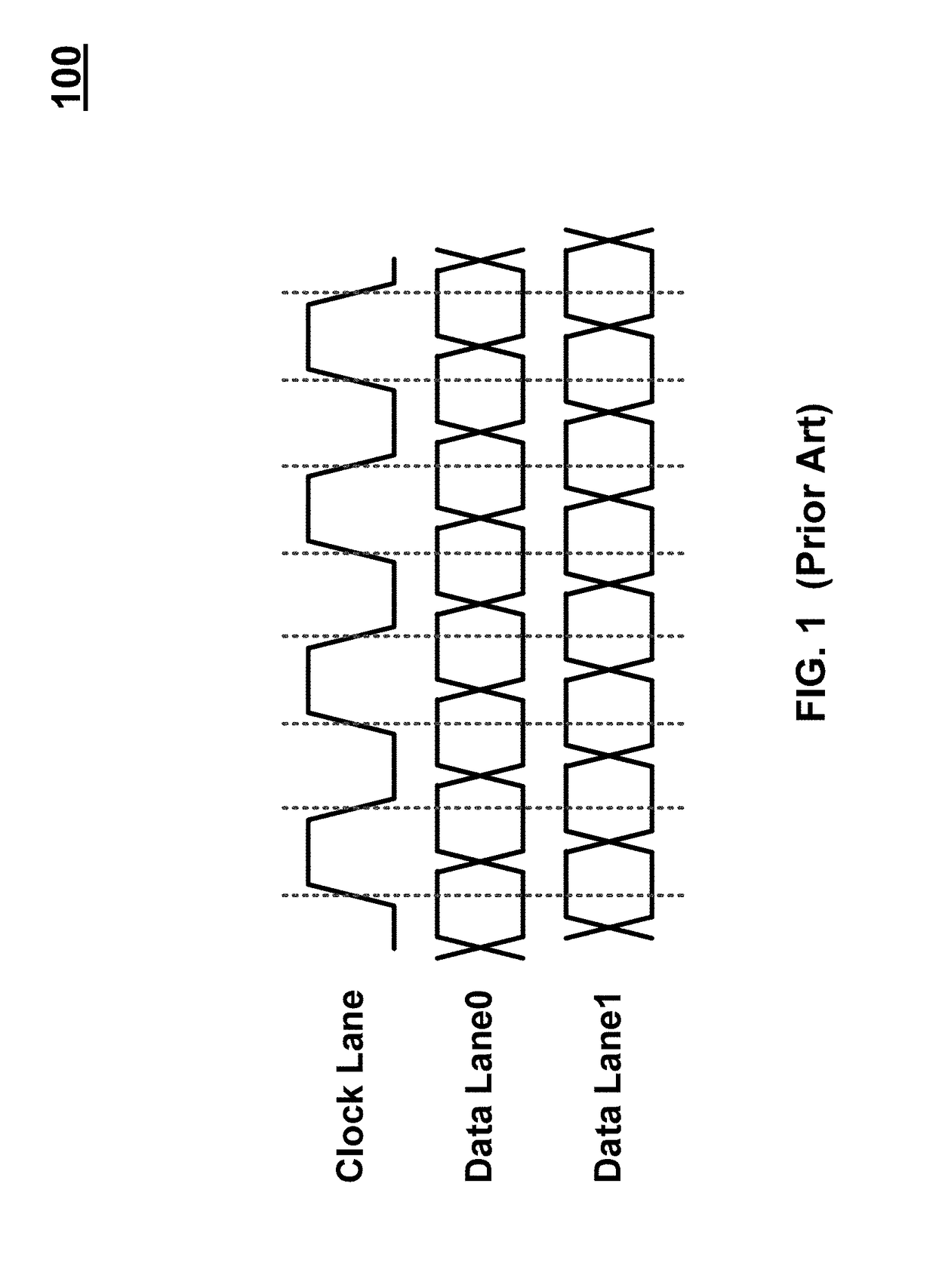

Repetitive IO Structure in a Phy for Supporting C-Phy Compatible Standard and/or D-Phy Compatible Standard

ActiveUS20180241382A1Reduce performance varianceReduce effortCommunication cablesLine-transmission detailsComputer moduleEngineering

A circuit in a physical unit (PHY) is disclosed, the circuit comprising two trios and a combo wire therebetween, wherein each of said trios includes three wires, and wherein said combo wire is configurable as a signal, floating, or any dc voltage, furthermore, a Quad-IO block is designed for transmit data in two D-PHY lanes with the combo wire configured as a signal wire or a C-PHY trio with the combo wire configured as a shielding wire, such that the same Quad-IO block can be instantiated multiple times in a physical unit for meeting different bandwidth requirements as well as for placing pads along a same direction for preventing performance difference between D-PHY lanes or C-PHY trios.

Owner:M31 TECH

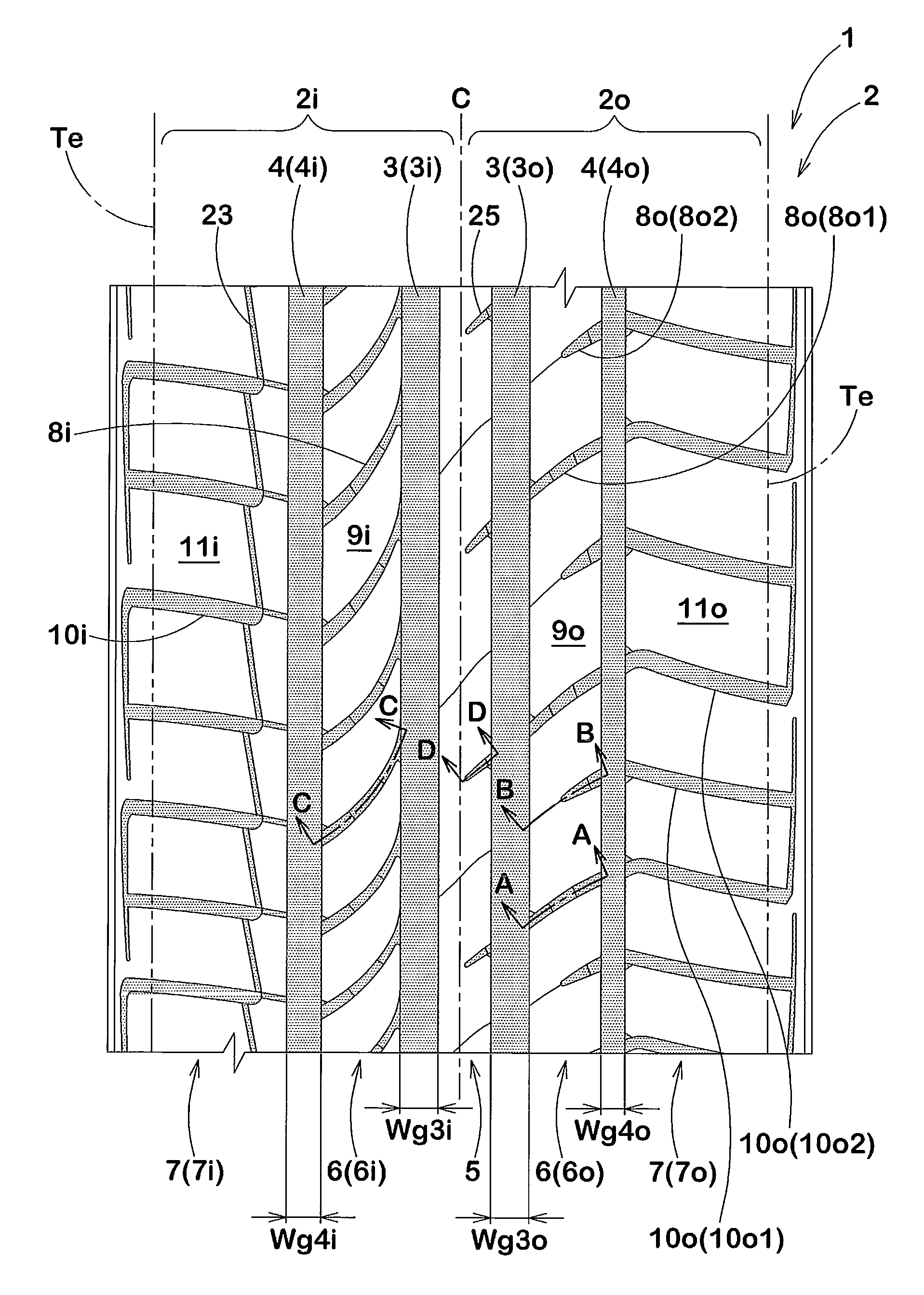

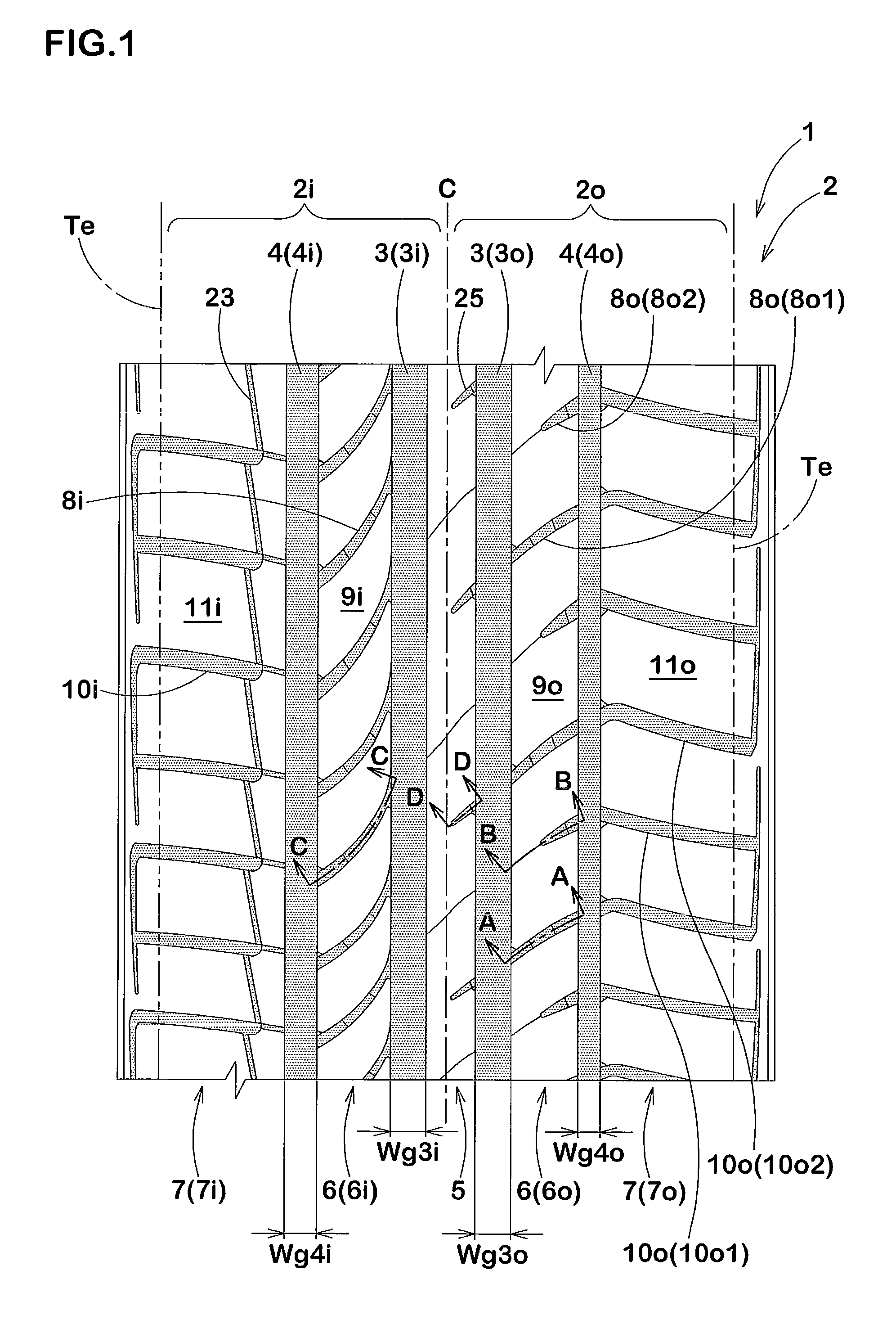

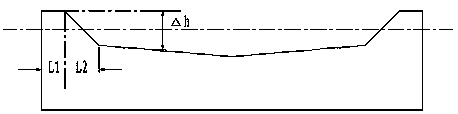

Pneumatic tire with asymmetric tread pattern

ActiveUS8550133B2Large influenceDifference in performanceTyre tread bands/patternsNon-skid devicesEngineeringTread

A tire having an asymmetric tread pattern that land proportion of outer side area 2o is larger than inner side area 2i, but having a reduced difference in drainage performance between tires on right and left wheels, the tire having tread surface 2 divided by four circumferential grooves 3 and 4 into center land 5, middle lands 6, 6 and shoulder lands 7, 7, wherein middle land 6o and shoulder land 7o in the outer side area 2o are divided respectively by outer middle lateral grooves 8o and outer shoulder lateral grooves 10o into blocks 9o and blocks 11o, inclination direction of the middle lateral grooves 8o is opposite to that of the shoulder lateral grooves 10o with respect to tire axial direction, and the lateral grooves 8o and 10o are inclined at an angle θmo between 5° and 45° and at an angle θso between more than 0° and not more than 40°, respectively.

Owner:SUMITOMO RUBBER IND LTD

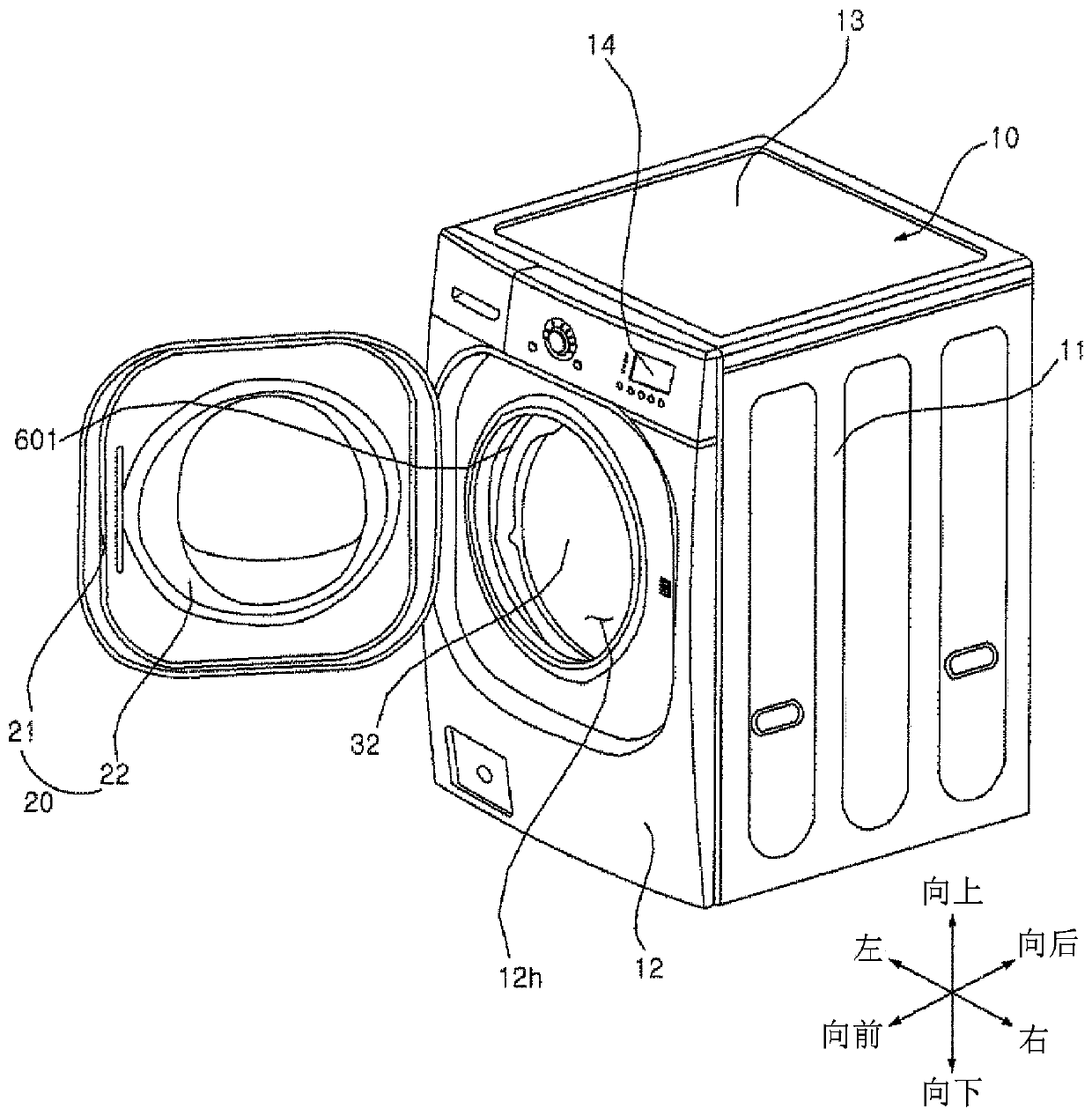

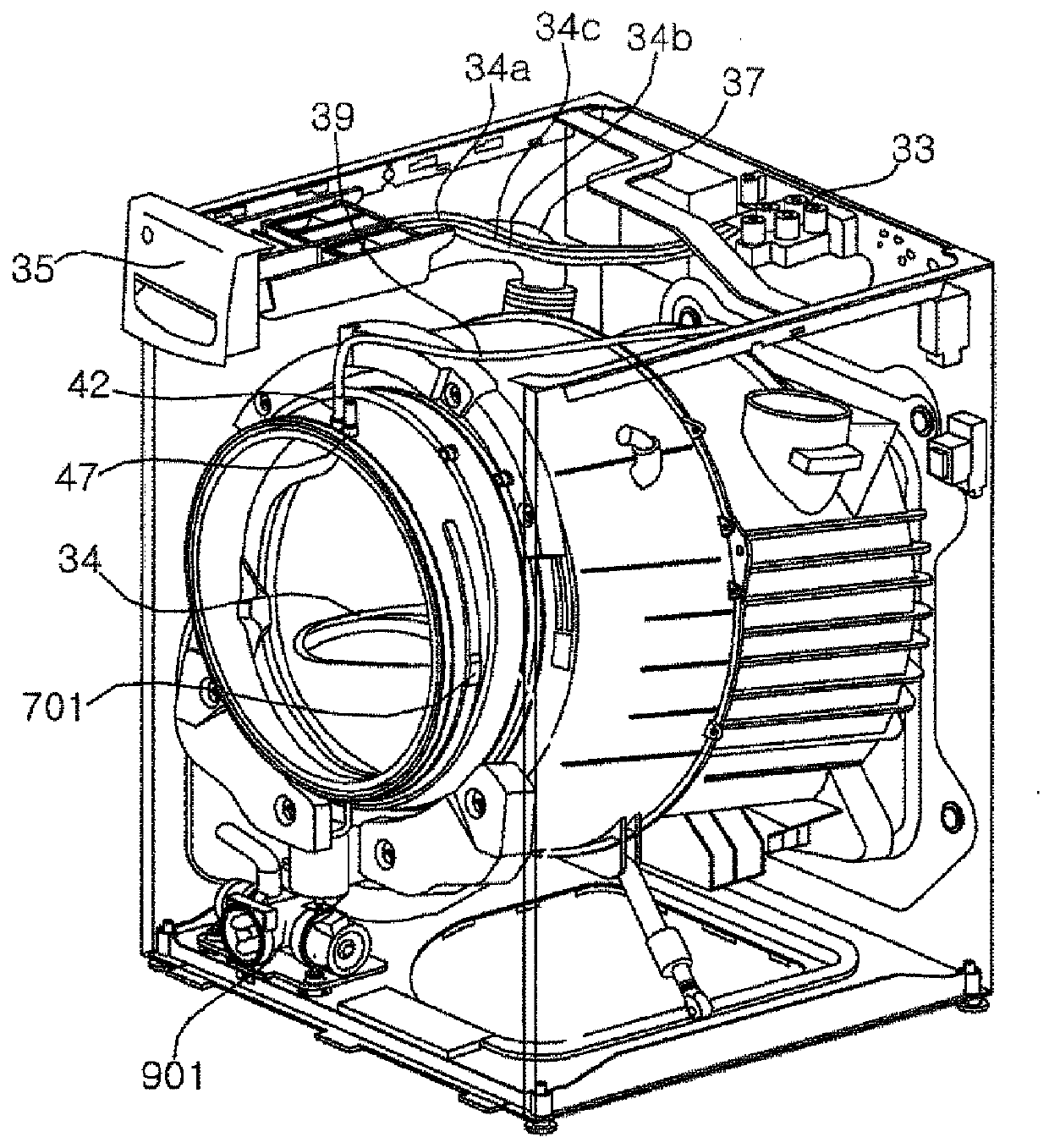

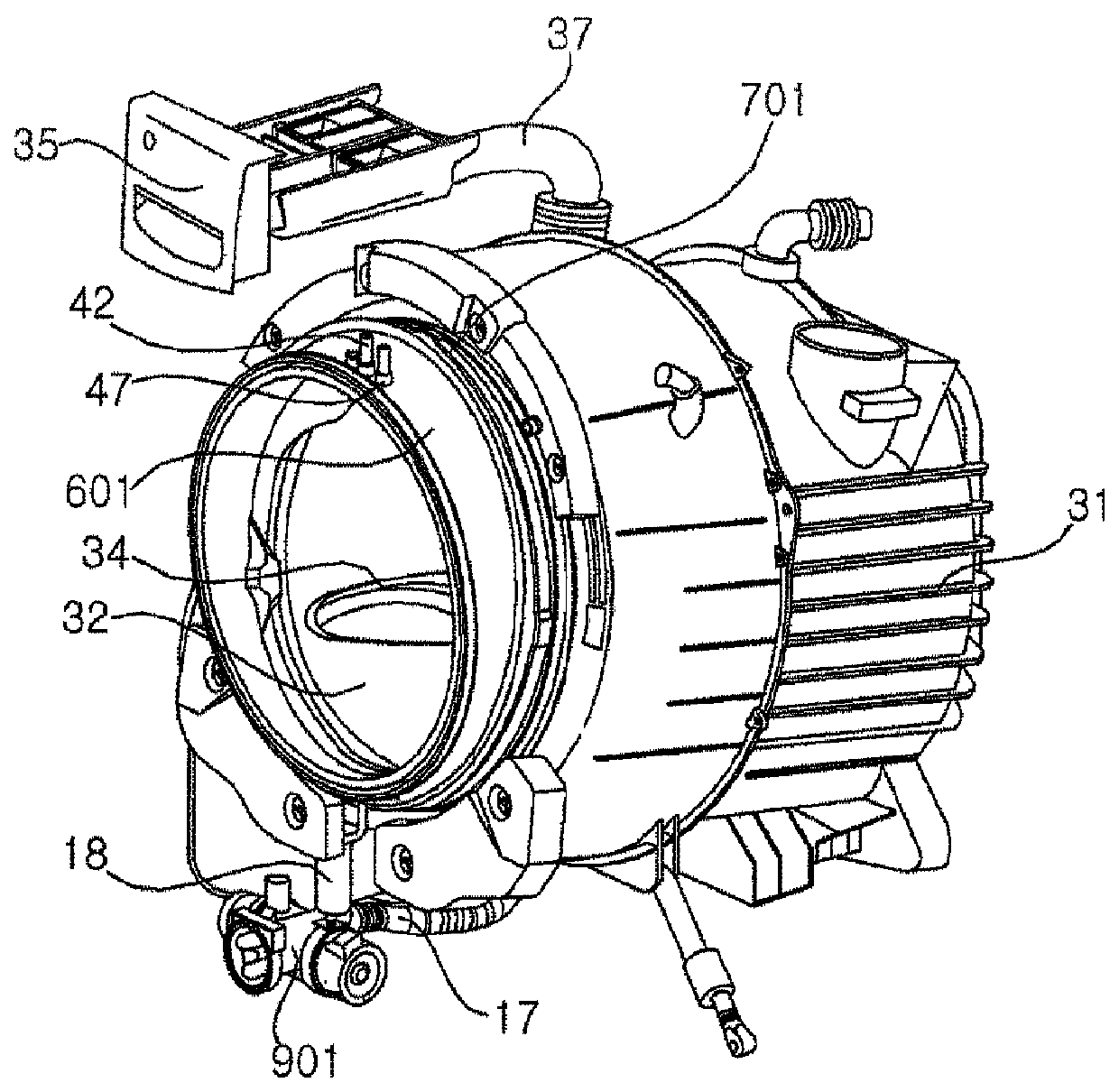

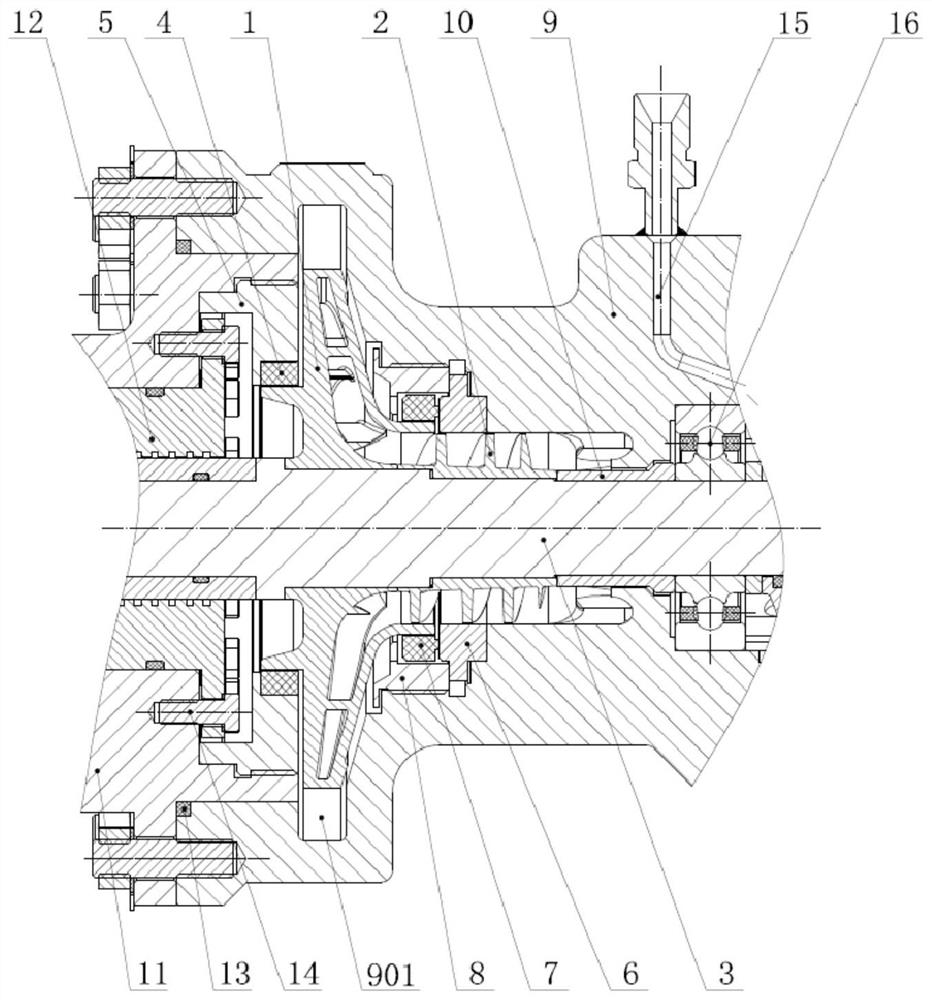

Washing machine

PendingCN110352274ASmooth releaseEasy to dryOther washing machinesControl devices for washing apparatusLaundry washing machineWasher

The present invention relates to a washing machine comprising: a casing having a insertion hole for inserting laundry thereinto on the front surface thereof; a tub disposed in the casing and containing laundry water and having an inlet communicating with the insertion hole; a drum, rotatably disposed within the tub, for accommodating laundry; a pump for pumping water discharged from the tub; a gasket for making the insertion hole communicate with the inlet of the tub and having a plurality of nozzles for spraying water into the drum; and a nozzle water supply pipe, fixed to the gasket and having an inlet through which water pumped by the pump flows, for dividing and guiding water that has flowed through the inlet into a first sub flow and a second sub flow, the nozzle water supply pipe including a plurality of first nozzle water supply ports, formed on a first flow passage to which the first sub flow is guided, for supplying the first sub flow individually to any two or more nozzles among the plurality of nozzles, and a plurality of second nozzle water supply ports, formed on a second flow passage to which the second sub flow is guided, for supplying the second sub flow individually to other two or more nozzles among the plurality of nozzles.

Owner:LG ELECTRONICS INC

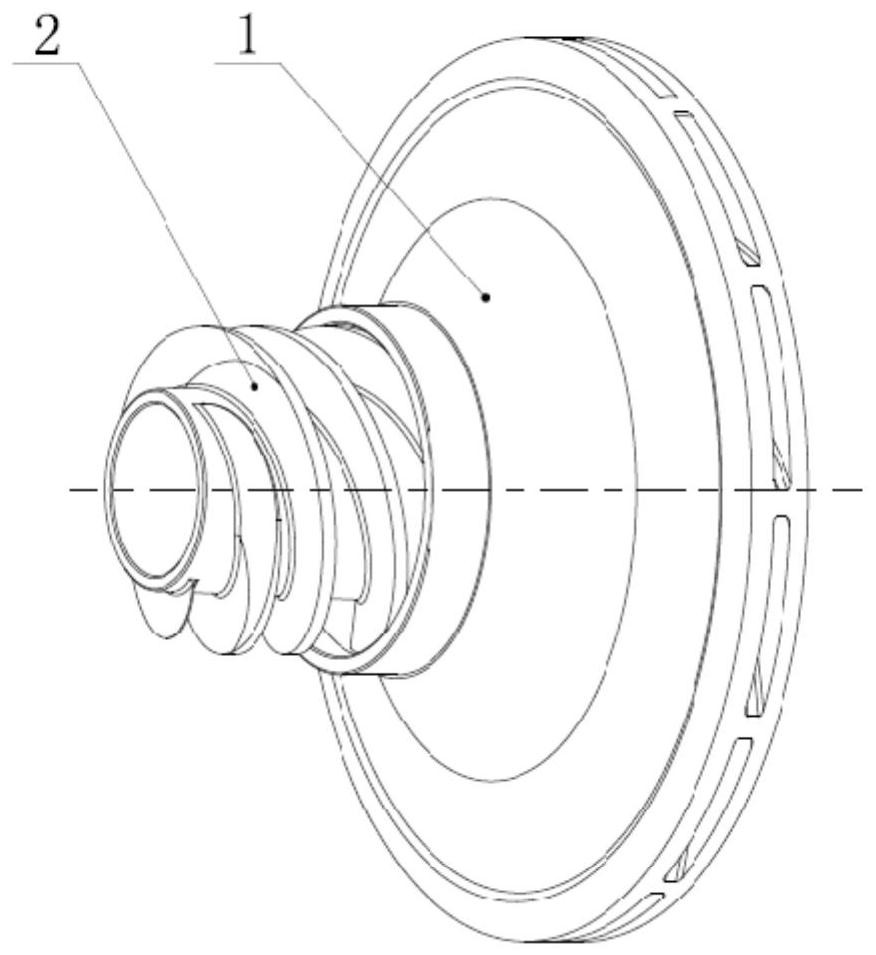

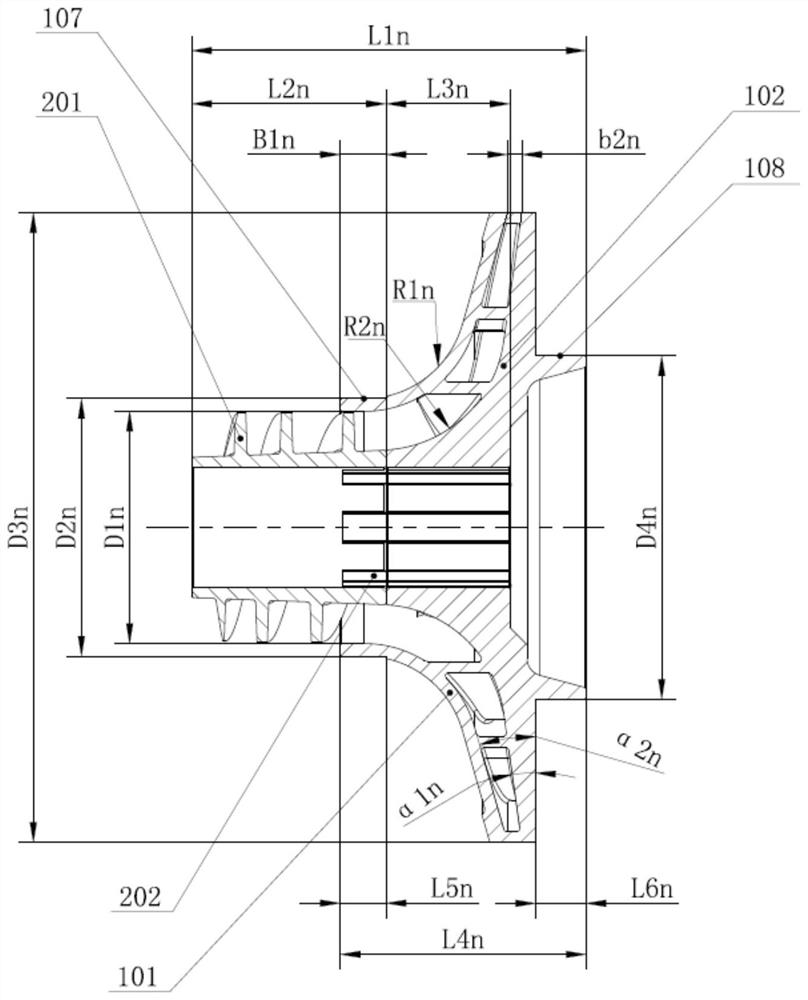

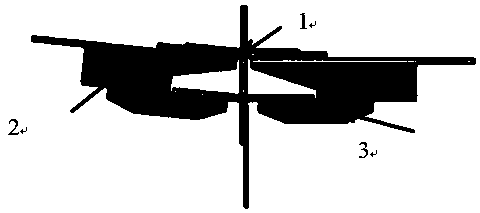

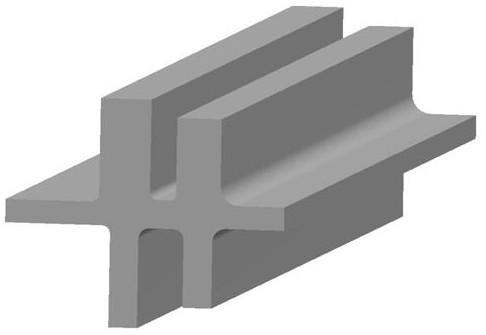

Efficient long-runner impeller low-specific-speed centrifugal pump

PendingCN113586513AImprove work efficiencyUniform change in flow areaPump componentsPumpsCircular discDrive shaft

The invention discloses an efficient long-runner impeller low-specific-speed centrifugal pump. The efficient long-runner impeller low-specific-speed centrifugal pump comprises a centrifugal impeller, an inducer, a transmission shaft, a centrifugal pump shell and sealing structures; the centrifugal impeller and the inducer are in rigid connection; the centrifugal impeller and the inducer are coaxial with the transmission shaft; the centrifugal impeller comprises a front cover plate and a rear cover plate which are in single-arc transition; and the sealing structures are arranged on the outer side of the front cover plate and the outer side of the rear cover plate correspondingly. According to the efficient long-runner impeller low-specific-speed centrifugal pump, the axial length is properly increased, the blade angle distribution of the centrifugal impeller is smoother, the inlet impact loss of the centrifugal impeller is reduced, the work efficiency of the low-specific-speed centrifugal pump is obviously improved, and the problem that due to the long and narrow runner characteristic of the low-specific-speed centrifugal pump, the impeller disc friction loss and the inlet impact loss of the low-specific-speed centrifugal pump are large, and consequently the efficiency of the low-specific-speed centrifugal pump is low is solved.

Owner:XI AN JIAOTONG UNIV

7-series aluminum alloy profile used for civil aircraft first rib and preparation method thereof

InactiveCN111411273AGuaranteed performance uniformityReduce temperature and performance varianceIngot castingAluminium alloy

The invention discloses a 7-series aluminum alloy profile used for a civil aircraft first rib and a preparation method thereof and belongs to the field of manufacturing of aluminum alloy profiles usedfor a civil aircraft. The profile comprises the following substances including, by weight, smaller than 0.08% of Si, smaller than 0.10% of Fe, 2.1%-2.4% of Cu, 2.0%-2.2% of Mg, smaller than 0.05% ofMn, smaller than 0.02% of Cr, 7.8%-8.2% of Zn, 0.02%-0.06% of Ti, 0.08%-0.12% of Zr and the balance Al. According to the 7-series aluminum alloy profile used for the civil aircraft first rib and the preparation method thereof, to meet requirements for the performance of the aluminum alloy profile used for the civil aircraft first rib, an ingot casting step heating isothermal reverse extrusion technology, a combined tooling uniform stretching technology and the like are adopted, the uniformity of the performance of different portions of the profile is guaranteed, and the 7-series aluminum alloyprofile meeting the using requirements of the domestic civil aircraft first rib is produced.

Owner:SHANDONG NANSHAN ALUMINUM +1

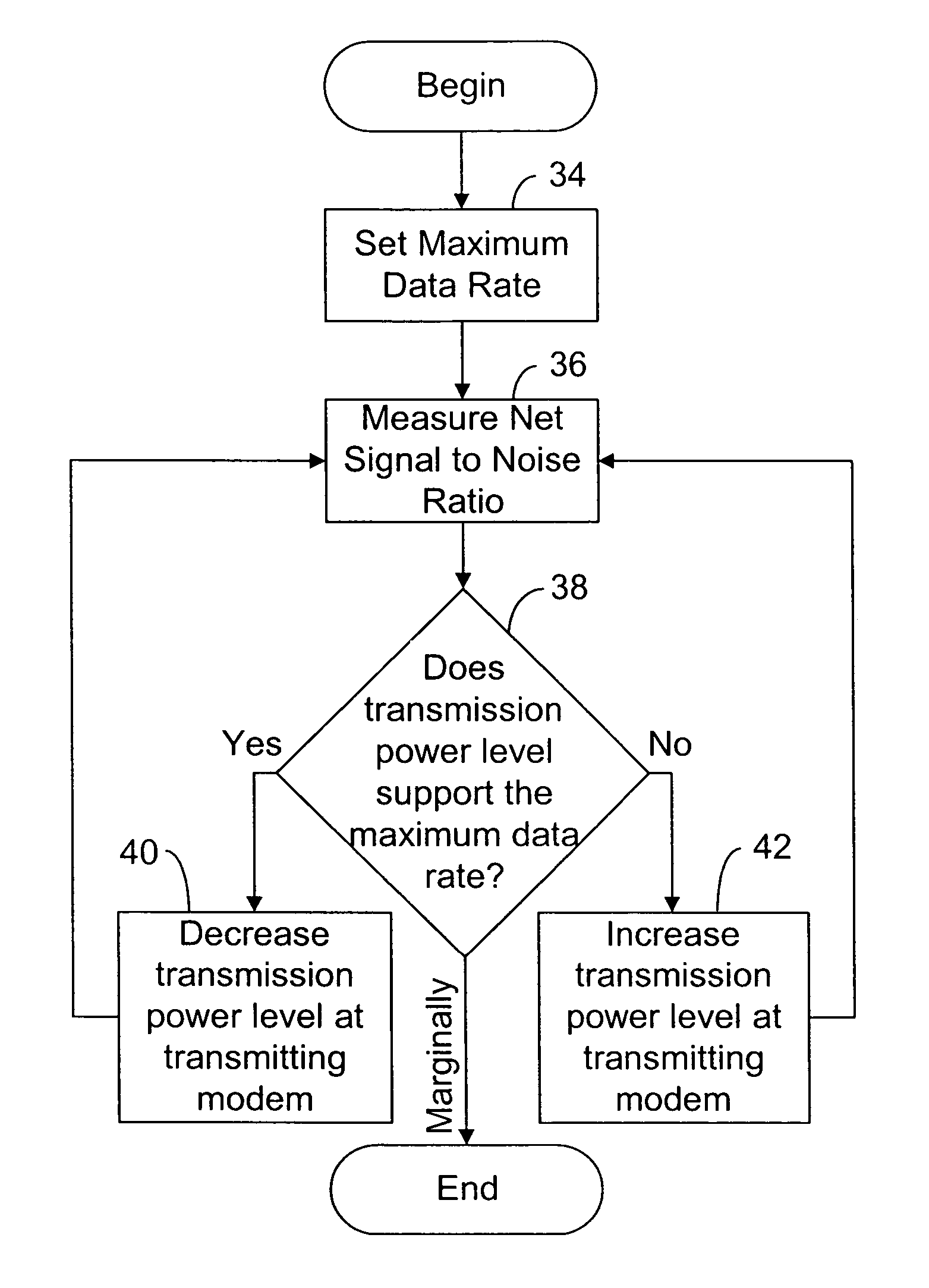

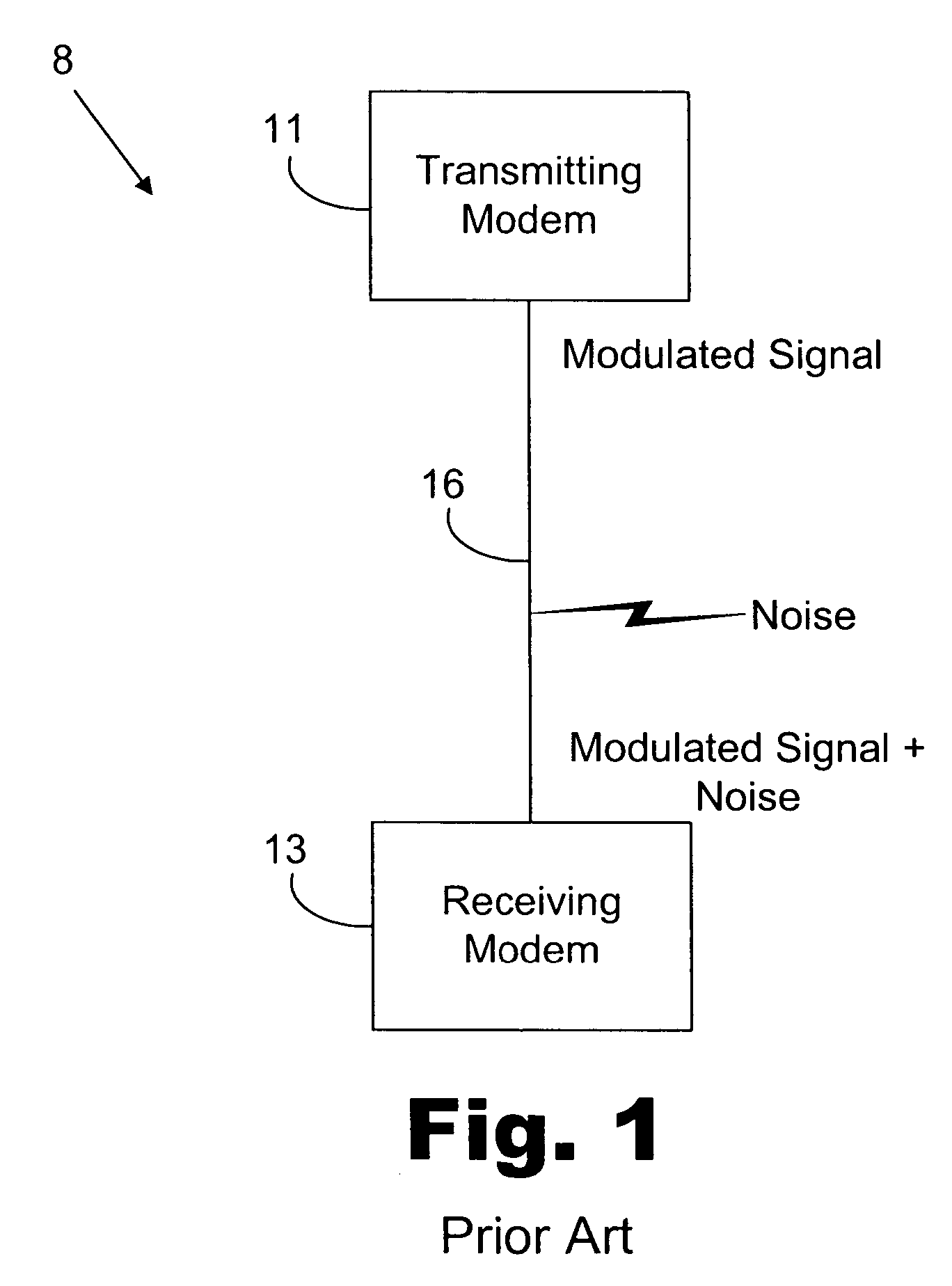

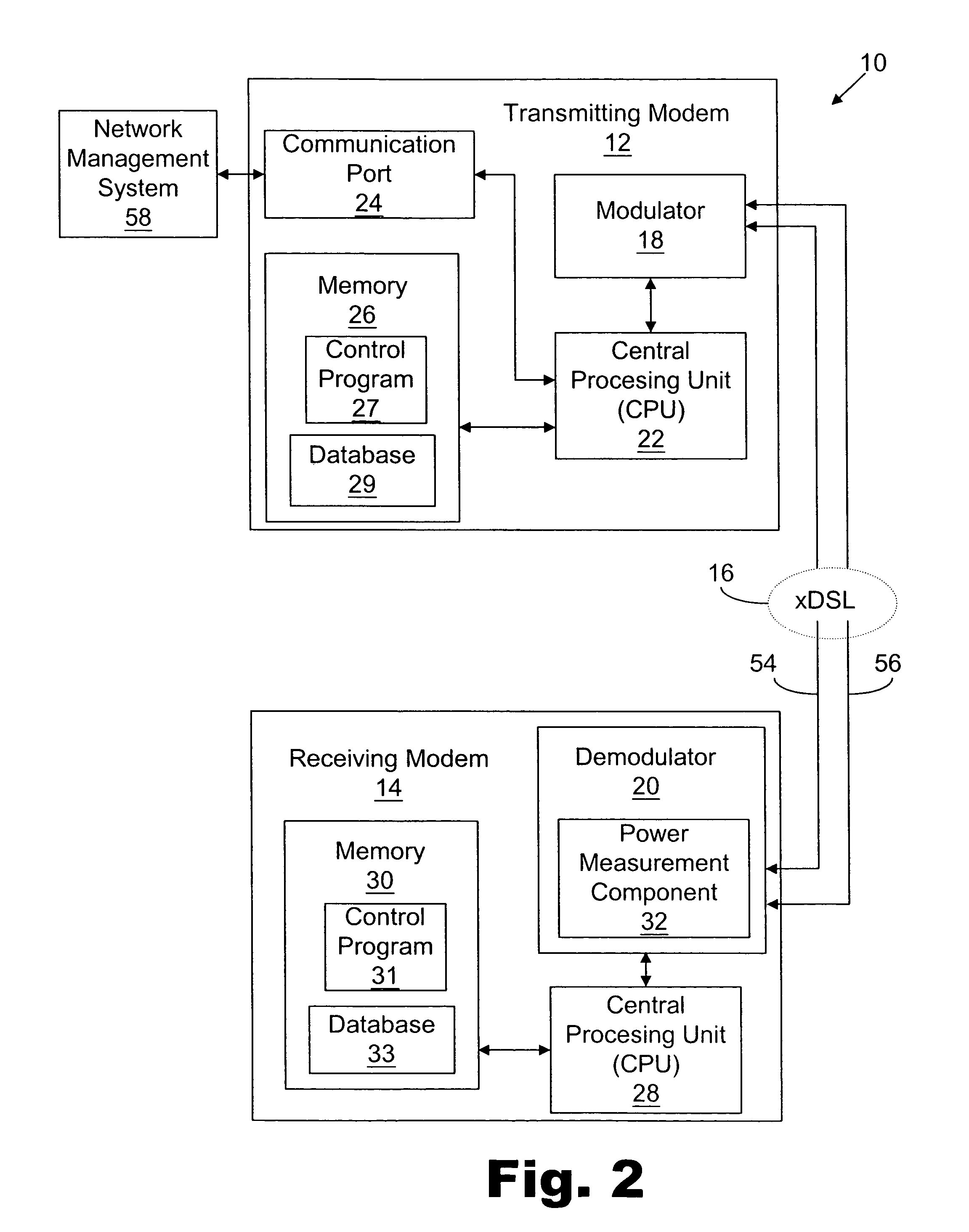

Performance customization system and process for optimizing xDSL performance

InactiveUS7916776B2Increase its present data rateReduce performance varianceEnergy efficient ICTTransmission monitoringCommunications systemModem device

Owner:PARADYNE CORP

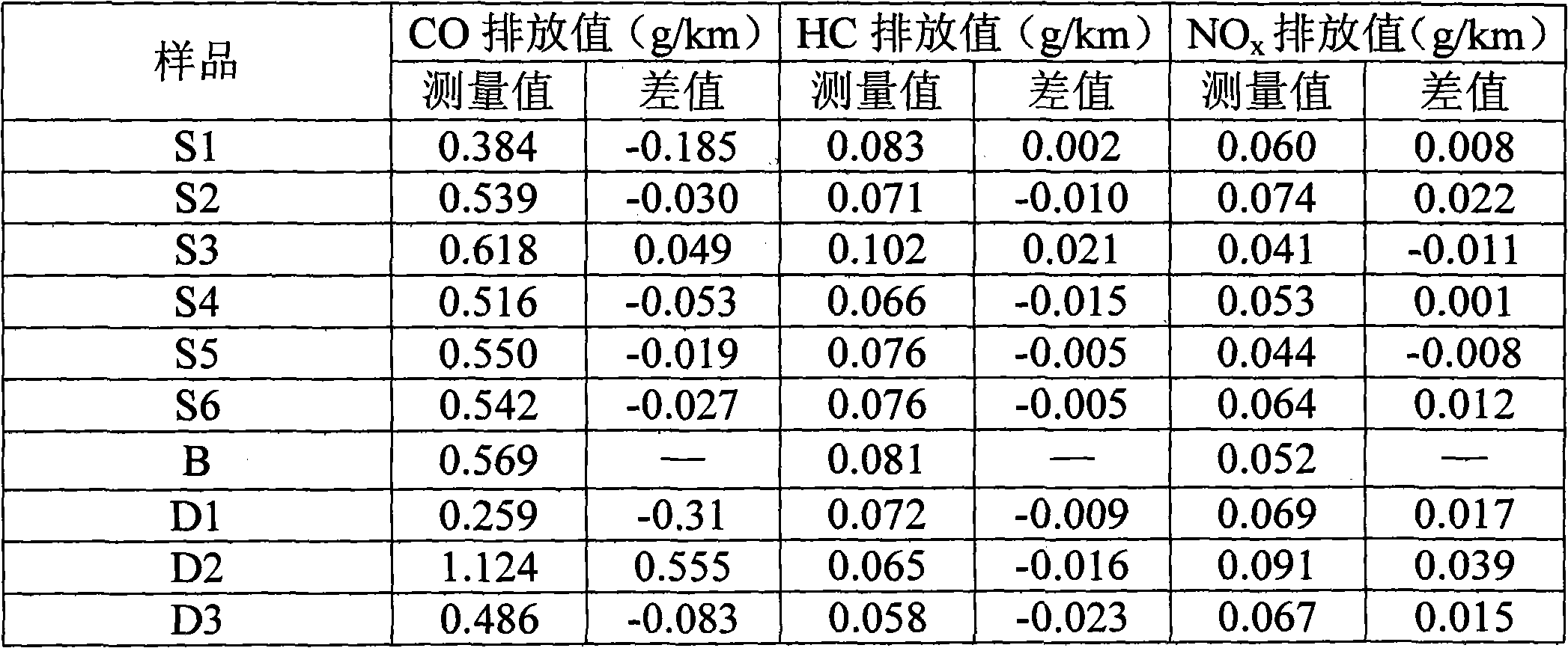

Catalyst degradation method

ActiveCN102107148AReduce performanceSimulate performance changesDispersed particle separationCatalyst activation/preparationCatalyst degradationPhosphate

The invention discloses a catalyst degradation method which comprises the following steps: impregnating the catalyst to be degraded in phosphoric acid or phosphate solution; then calcining the impregnated catalyst; and finally performing thermal aging treatment. Difference in performance between the catalyst after the degradation treatment by the method and the practically used catalyst is relatively small, and the precision is high.

Owner:ZHEJIANG GREAT CHEM SCI & TECH

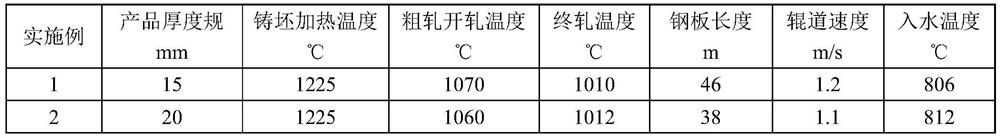

Rolling process plate form control method for high-strength steel with thickness specification being 6 mm or below

ActiveCN110280601AReduce temperature difference in directionReduce water residueProfile control deviceThick plateSheet steel

The invention discloses a rolling process plate form control method for high-strength steel with the thickness specification being 6 mm or below. The plate form control method comprises the procedures of heating, rough rolling, finish rolling, controlled cooling and hot straightening. In the heating and rolling processes, the integral temperature uniformity of a casting blank and an intermediate blank and structure state uniformity after phase changes happen are sufficiently considered, and the problems that in the medium-thick plate steel ball rolling process, due to the reason in the aspect of the technology, stress is uneven, stress is generated due to the uneven temperature and the structure difference, and consequently irregular deformation is caused are solved. According to the plate form control method, the blank thickness compression ratio is smaller than or equal to 20, the elongation ratio is smaller than or equal to 16.5, and the lateral spread ratio meets the formula: 1.0<=W<=1.4; the thickness of an obtained steel plate is smaller than or equal to 6 mm, and according to the steel plate performance, the yield strength is larger than or equal to 355 MPa; and the surface irregularity of the steel plate is smaller than or equal to 8 mm / 2m.

Owner:TANGSHAN HEAVY PLATE CO LTD +2

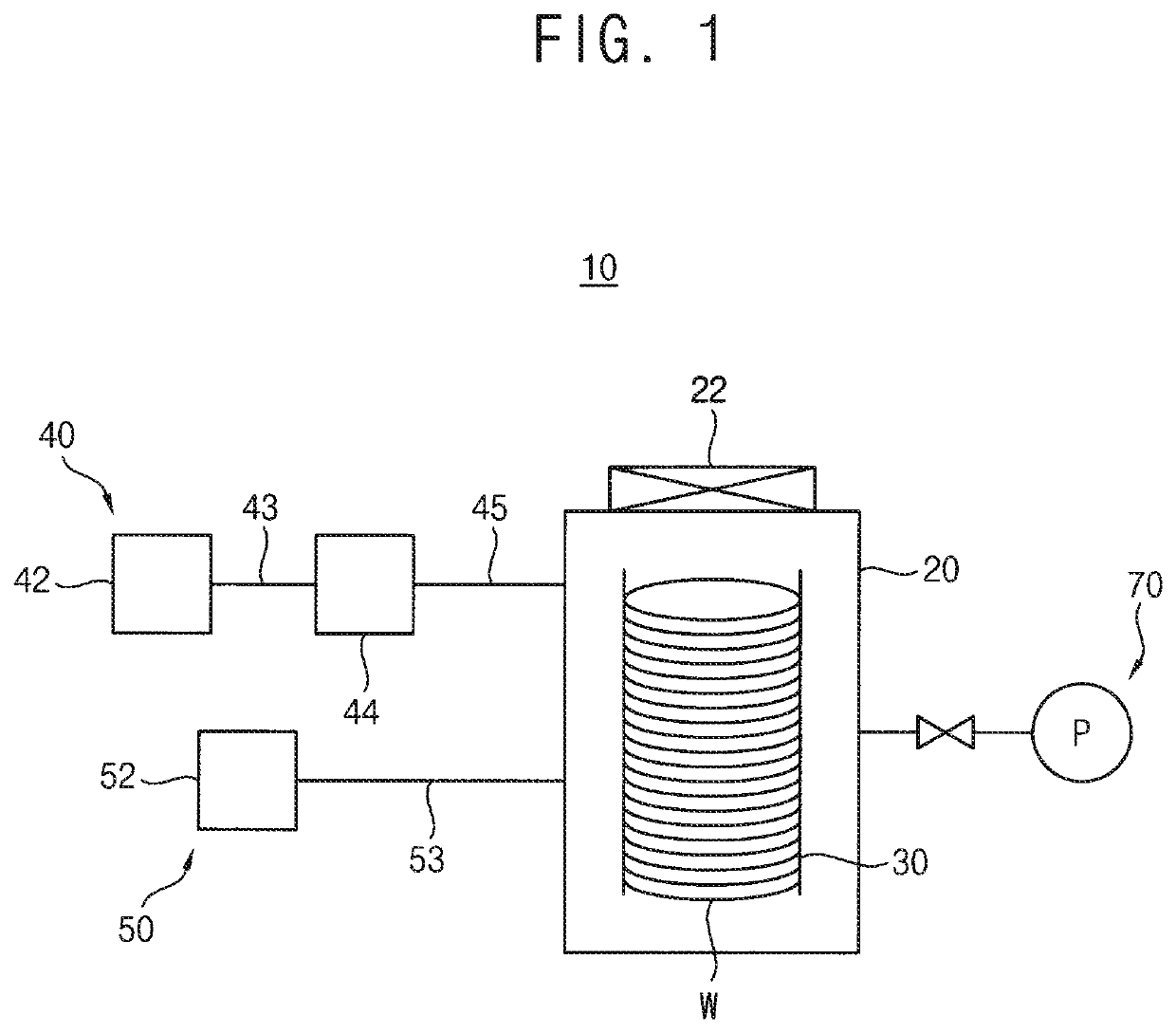

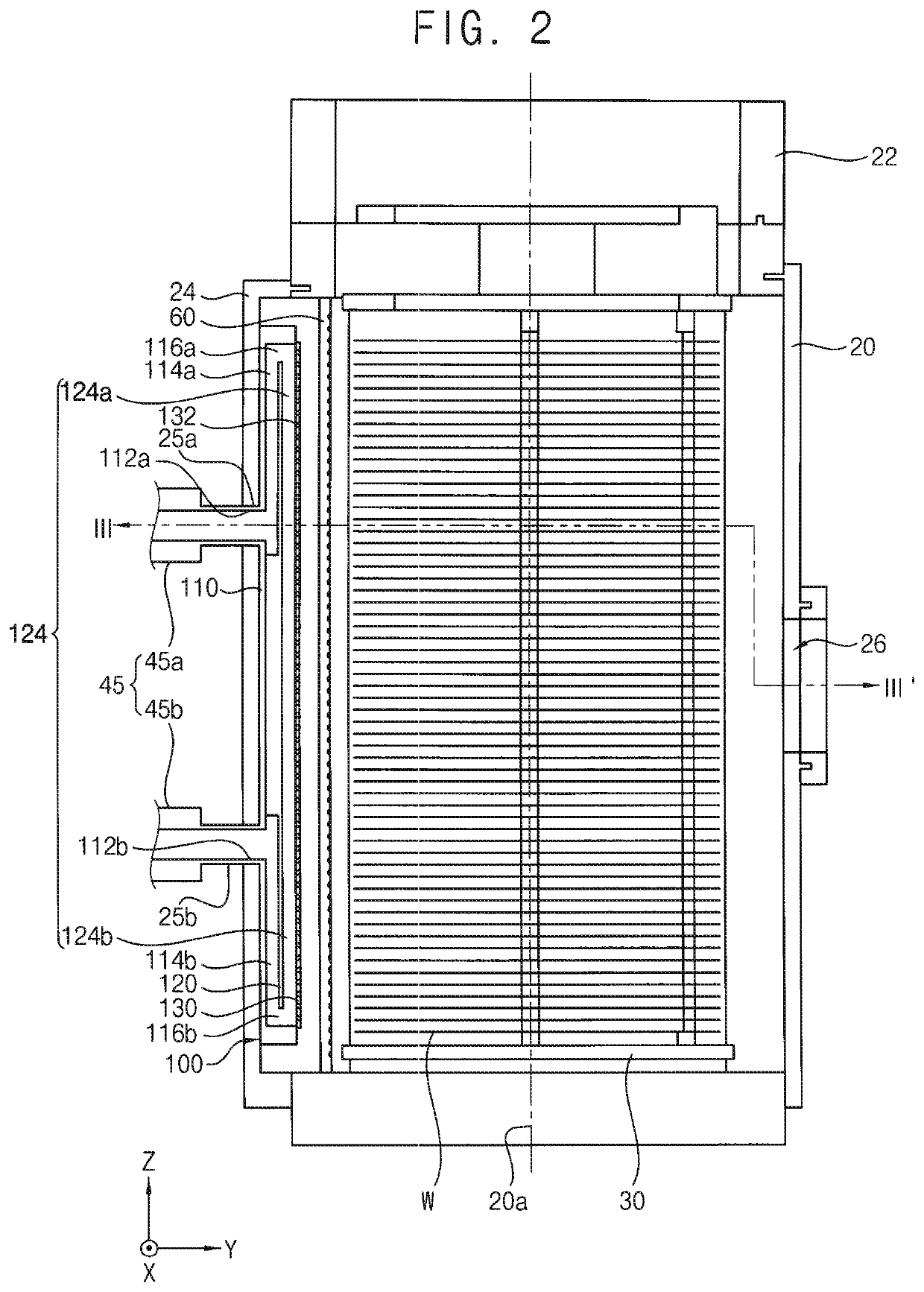

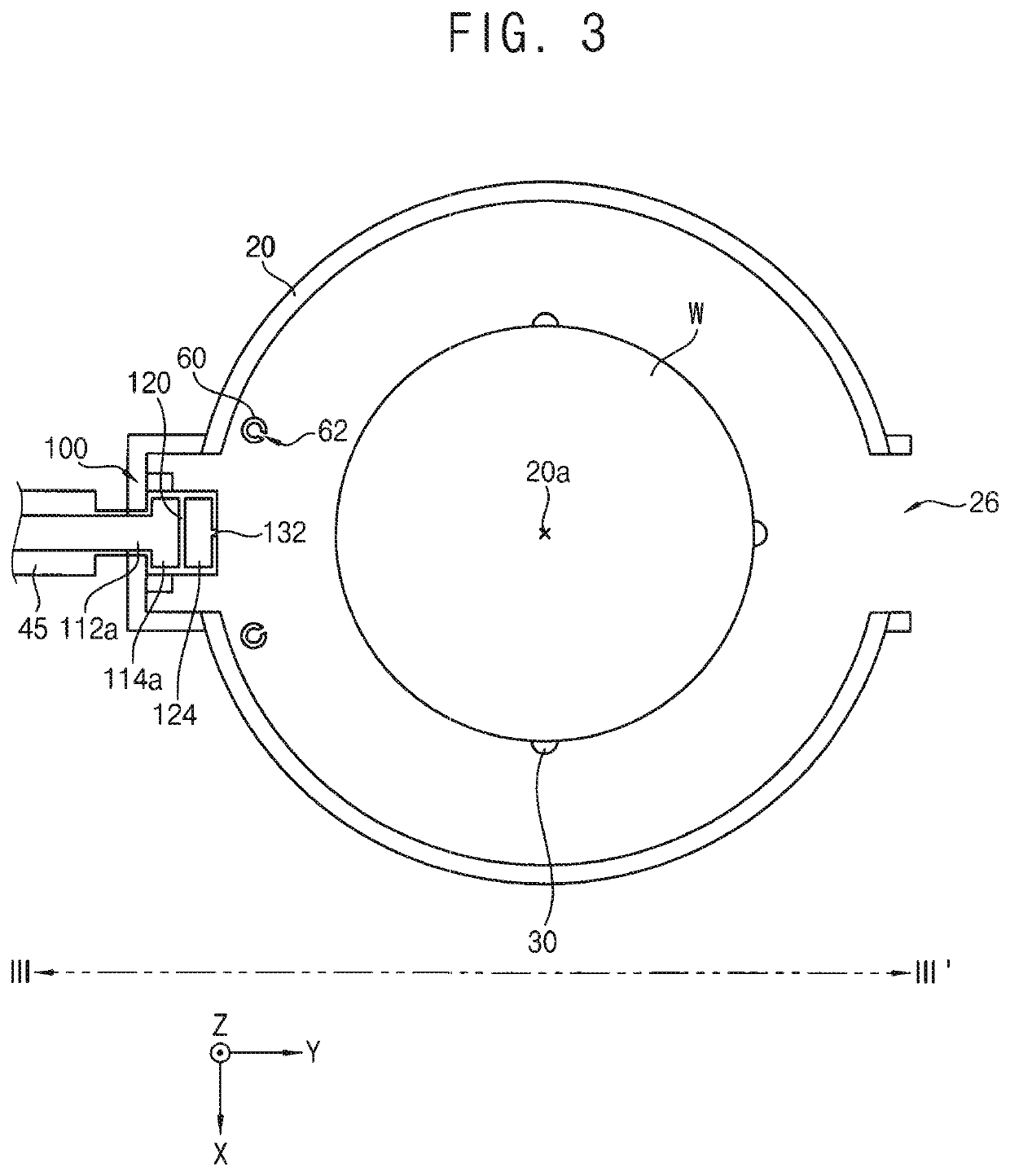

Gas injectors and wafer processing apparatuses having the same

ActiveUS11021796B2Improve semiconductor device performanceUniform temperatureSemiconductor/solid-state device manufacturingCleaning using gasesWaferingEngineering

A gas injector includes first and second gas introduction passages extending in a first direction toward a central axis of a process chamber respectively, a first bypass passage extending from the first gas introduction passage in a second direction that is substantially perpendicular to the first direction, a second bypass passage extending from the second gas introduction passage in a reverse direction to the second direction, a first distribution passage isolated from the first bypass passage in the first direction and extending from an outlet of the first bypass passage in the reverse direction to the second direction, a second distribution passage isolated from the second bypass passage in the first direction and extending from an outlet of the second bypass passage in the second direction, and a plurality of spray holes in an outer surface of the first and second distribution passages and configured to spray the process gas.

Owner:SAMSUNG ELECTRONICS CO LTD

Fuse

InactiveUS10340111B2Reduce performance varianceEasy to manufactureEmergency protective devicesEngineeringElectrical and Electronics engineering

Owner:TOYODA IRON WORKS CO LTD

Low-crack-sensitivity steel plate with yield strength of 960MPa and manufacturing method of low-crack-sensitivity steel plate

ActiveCN114752851ASolve QuenchingSolve cutting problemsProcess efficiency improvementSteelmakingTempering

The invention relates to a low-crack-sensitivity steel plate with yield strength of 960MPa, which comprises the following chemical components in percentage by weight: 0.06 to 0.10 percent of C, less than or equal to 0.20 percent of Si, 0.70 to 1.00 percent of Mn, 0.015 to 0.035 percent of Al, 0.015 to 0.025 percent of Ti, 1.15 to 1.35 percent of Cr, 0.001 to 0.005 percent of B, 0.0010 to 0.0050 percent of Ca, less than or equal to 0.015 percent of P, less than or equal to 0.003 percent of S, less than or equal to 0.0015 percent of O, less than or equal to 0.0030 percent of N, less than or equal to 0.00015 percent of H and the balance of Fe and inevitable impurity elements, and the carbon equivalent CEV is less than or equal to 0.54 percent. The production process comprises the following steps: electric furnace or converter steelmaking-gt; lF refining-gt; vD or RH high vacuum degassing-gt; continuous casting-gt; heating rolling-gt; carrying out online quenching-gt; and tempering. The steel plate structure is a fine tempered sorbite structure, and the grain size is smaller than or equal to 30 microns; the yield strength of the steel plate is larger than or equal to 960 MPa, the tensile strength of the steel plate is larger than or equal to 1000 MPa, and the ductility of the steel plate is larger than or equal to 10%; and transverse and longitudinal impact toughness Akv at-40 DEG C is greater than or equal to 30J.

Owner:JIANGYIN XINGCHENG SPECIAL STEEL WORKS CO LTD

Precise forging-continuous rolling production technology of large and heavy single molybdenum rod

ActiveCN103042389BRealize deep processingIncrease productivityTemperature control deviceOther manufacturing equipments/toolsThermal treatmentContinuous rolling

The invention provides a precise forging-continuous rolling production technology of a large and heavy single molybdenum rod. The production technology comprises the following steps of: 1, carrying out billet forging on the molybdenum rod by a precision forging machine to obtain a precision forging bar; 2, heating the precision forging bar; 3, rolling for the first time by a Y-shaped three-roller continuous mill to obtain a rolled molybdenum rod; 4, heating the rolled molybdenum rod; and 5, rolling for the second time by the Y-shaped three-roller continuous mill and obtaining the large and heavy single molybdenum rod of which the piece weight is 45-50kg. Deep processing of a molybdenum bar is successfully achieved by setting and optimizing each parameter in precision forging, thermal treatment and continuous rolling processes; the large and heavy single molybdenum rod, which is suitable for subsequent wire drawing, and of which the piece weight is 45-50kg, is finally produced; and the production efficiency is obviously improved. The piece weight of the molybdenum rod produced by the production technology is much greater than that of the molybdenum rod produced by a traditional technology; and the precise forging-continuous rolling production technology has no welding spot on the whole, and is even in internal organization, high in product quality and suitable for large-scale industrial production.

Owner:JINDUICHENG MOLYBDENUM CO LTD

Ceramic silver plating process

InactiveCN101913914BReduce performance varianceGet rid of the status quo of random constructionAqueous sodium hydroxideOil water

The invention belongs to a ceramic under-glaze decoration process, and in particular relates to a ceramic silver plating process. The process comprises the following steps of: after firing a blank, rendering with white glaze; spraying solution A; and firing the blank at the temperature of between 1,100 and 1,500 DEG C; coating a silver foil on a fired product and producing a texture effect; and spraying silver glaze and performing tempering treatment, namely finishing a ceramic silver plating process. The solution A is obtained by the method of: fully mixing 100 weight parts of silver powder,90 to 120 weight parts of 783-isophorone, 0 to 1 volume part of sodium hydroxide aqueous solution with the mass concentration of 20 to 50 percent for 5 to 10 minutes. The ceramic silver plating process of the invention gets rid of the current situation of random construction, so that the quality is easier to control and the effect difference among batches of products is reduced; in addition, the ceramics obtained by the process changes the effect of a single color in the past and has very high craft appreciation.

Owner:HOMEPAINT WOODCARVING

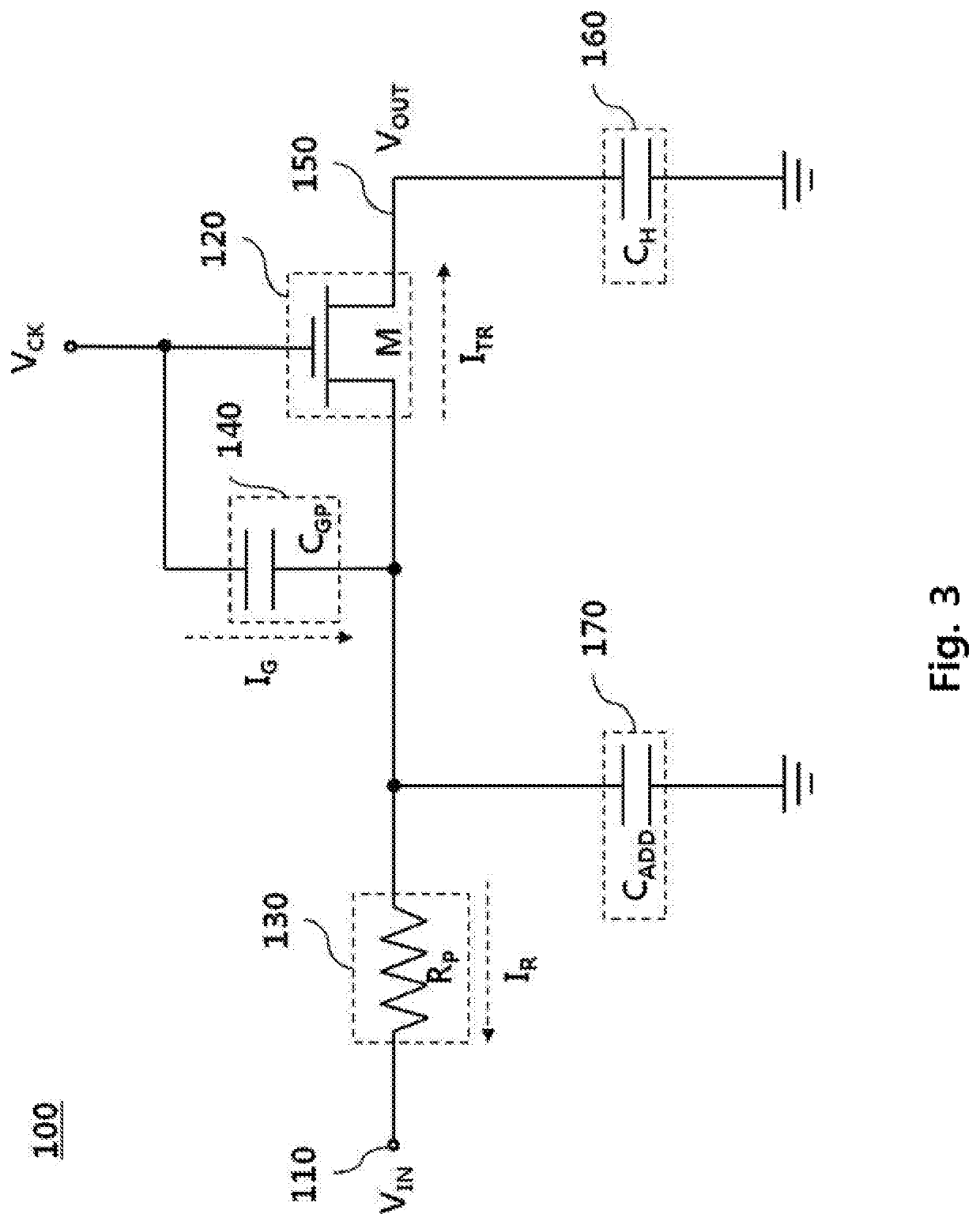

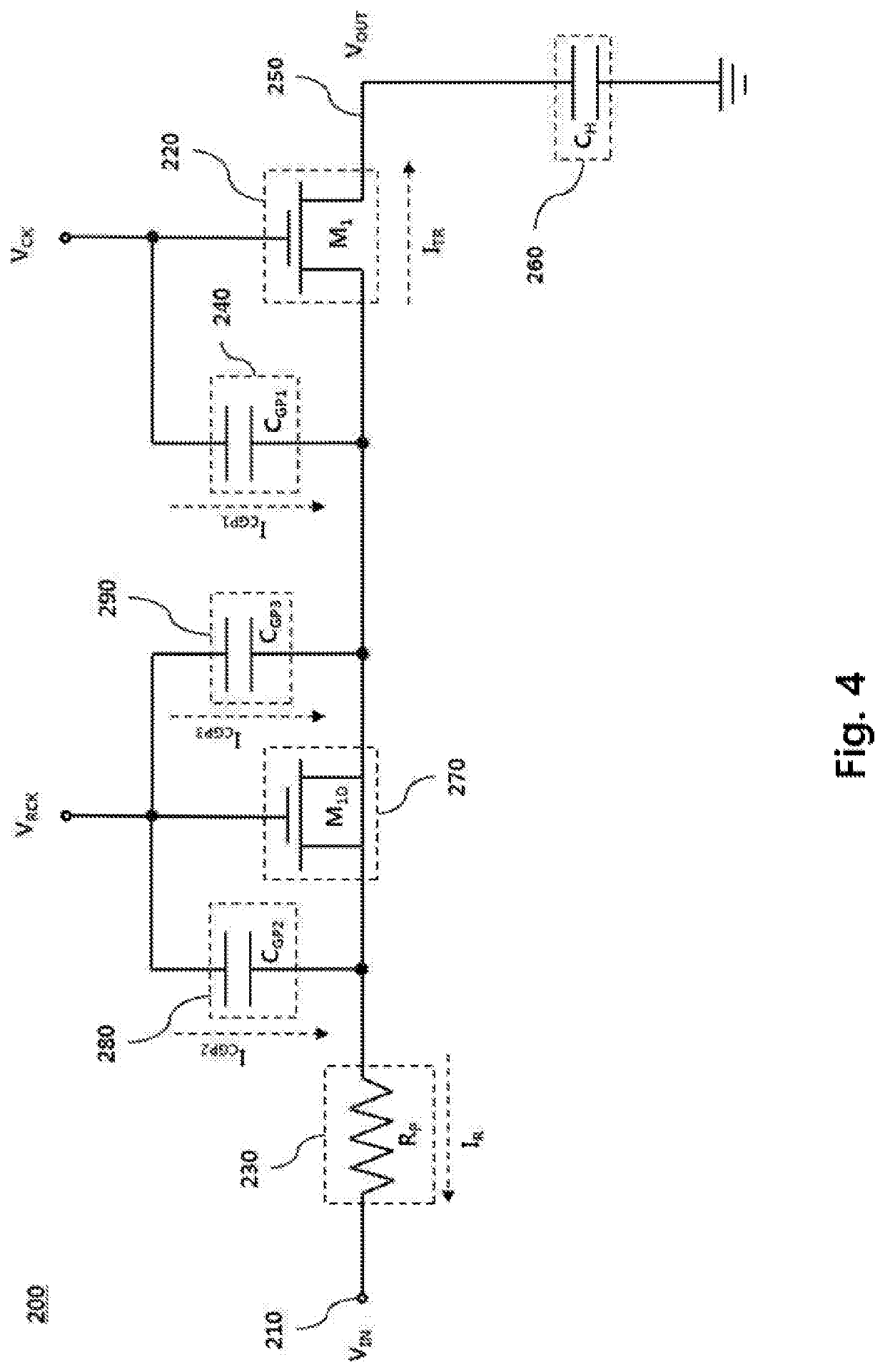

Transistor circuit and electronic circuit having same

ActiveUS20200343886A1Reduce secondary nonlinearityReduce non-linearityElectronic switchingHemt circuitsParasitic capacitance

A transistor circuit having a dummy capacitor or a dummy transistor between an input terminal and a transistor is disclosed. The circuit improves secondary nonlinear characteristics of the transistor attributable to one or more parasitic components and a clock signal. The transistor circuit includes an input terminal configured to receive an input signal, a transistor having a gate configured to receive a clock signal, and a source connected to the input terminal, a connection line between the input terminal and the transistor and having a parasitic resistor therein, a parasitic capacitor between the input terminal and the transistor, and a dummy transistor having a first terminal that is connected to the connection line between the input terminal and the transistor.

Owner:DONGBU HITEK CO LTD

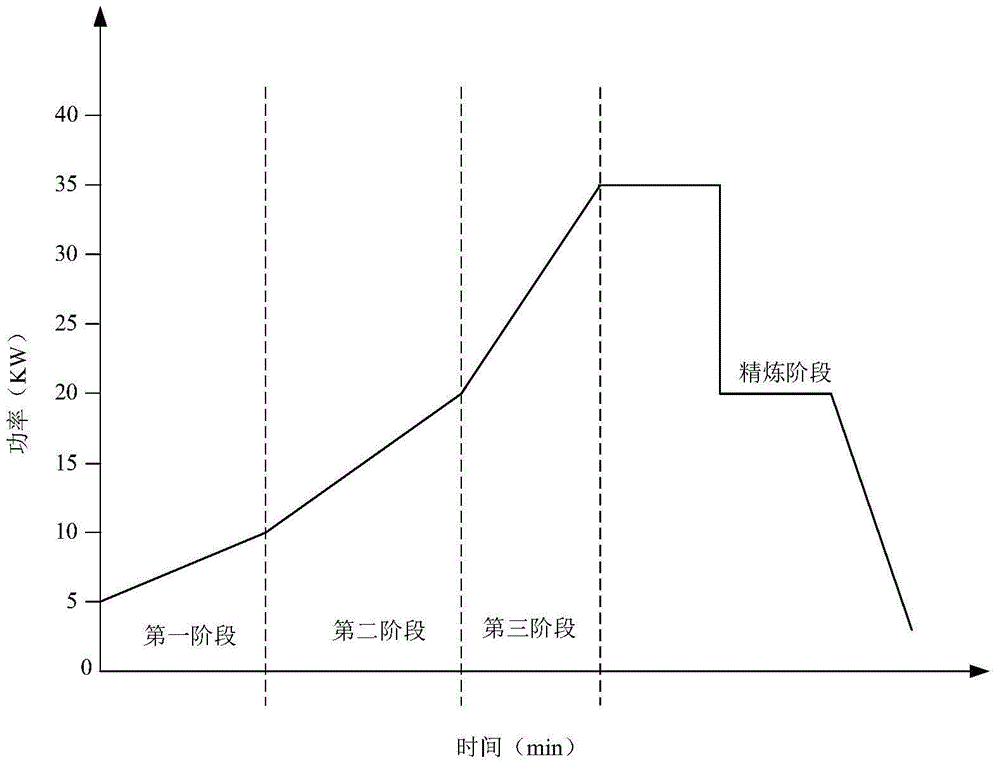

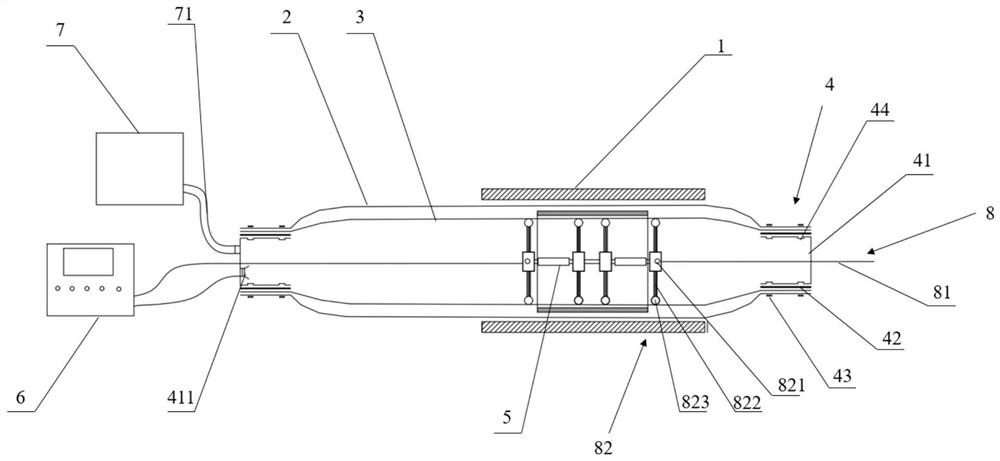

Alnbbre refiner with low cooling rate sensitivity and high nucleation ability for cast aluminum alloy and preparation method thereof

The invention discloses a low-cooling-rate-sensitivity high-nucleation-capability AlNbBRE grain refiner for cast aluminum alloy and a method for preparing the refiner by adopting induction smelting; the ingredients of the refiner are Al-xNb-yB-zRE, wherein x is larger than 0.01wt% and smaller than or equal to 6wt%, y is larger than 0.01wt% and smaller than or equal to 3wt%, z is larger than 0.01wt% and smaller than or equal to 1wt%, and the balance is Al; RE is one of or a mixture of two of La, Ce, Nd, Er, Gd, Y, Yb and Sc. The method is simple in preparation process and capable of accurately controlling the ingredients of the refiner. The refiner is excellent in refining effect when being used for performing grain refinement on cast aluminum-silicon alloy and is relatively low in cooling rate sensitivity on the refining effect of the positions, complicated in shape and different in thickness, of a cast piece, namely of the positions different in cooling rate; the mechanical properties of the refined alloy are remarkably improved; the performance differences of the positions which are different in cooling rate are remarkably reduced.

Owner:BEIHANG UNIV

Ultraviolet curing device for annular sample of lining pipe and application of ultraviolet curing device

Owner:CHINA UNIV OF GEOSCIENCES (WUHAN)

Catalyst degradation method

ActiveCN102107148BReduce performanceSimulate performance changesDispersed particle separationCatalyst activation/preparationCatalyst degradationPhosphate

The invention discloses a catalyst degradation method which comprises the following steps: impregnating the catalyst to be degraded in phosphoric acid or phosphate solution; then calcining the impregnated catalyst; and finally performing thermal aging treatment. Difference in performance between the catalyst after the degradation treatment by the method and the practically used catalyst is relatively small, and the precision is high.

Owner:ZHEJIANG GREAT CHEM SCI & TECH

Method for manufacturing light-emitting device packages, light-emitting device package strip, and light-emitting device package

ActiveUS9930750B2Address rising pricesReduce performance varianceNon-electric lightingPoint-like light sourcePhosphorEngineering

A method for manufacturing a chip scale package (CSP) for a light-emitting diode (LED). The method may include a light-emitting device mounting step for mounting a plurality of light-emitting devices on a substrate strip, a phosphor forming step for forming a phosphor on the plurality of light-emitting devices, a reflective member forming step for forming a reflective member on the substrate strip to surround the phosphor, and a package singulation step for singulating unit packages by cutting the substrate strip and the reflective member.

Owner:LUMENS

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com