Catalyst degradation method

A catalyst and oxidation technology, which is applied in the direction of catalyst activation/preparation, chemical instruments and methods, physical/chemical process catalysts, etc., can solve the problem of low precision, achieve high precision and reduce the effect of performance difference

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

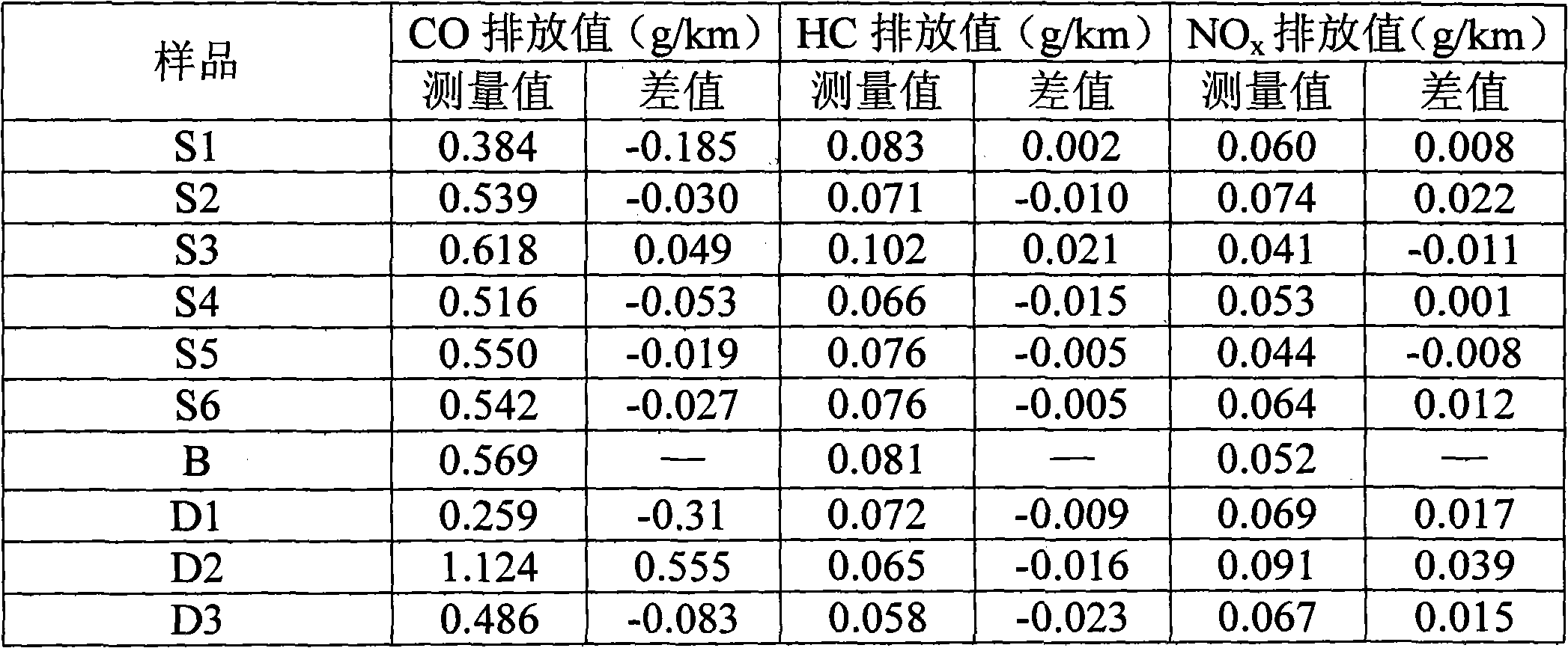

Examples

Embodiment 1

[0042] This example is used to illustrate the method disclosed in the present invention.

[0043] Place catalyst A in concentration of 0.4mol / L (NH 4 ) 2 HPO 4 solution for 12h, and then calcined in air at 500°C for 3h.

[0044] Then the catalyst obtained by the above-mentioned treatment is placed in a high-temperature calciner, and in a vacuum environment (pressure is 10 3 Pa) at 1000°C for 15h. A degraded catalyst sample S1 was prepared.

Embodiment 2

[0046] This example is used to illustrate the method disclosed in the present invention.

[0047] Place catalyst A in concentration of 0.05mol / L (NH 4 ) 2 HPO 4 In the solution for 2 hours, the catalyst was taken out, placed in an oven, and dried at a temperature of 110° C. for 3 hours. Then calcined at 450°C for 8h.

[0048] The catalyst obtained by the above treatment is placed in a quartz tube reactor, and the aging atmosphere is an oxidation-reduction oscillation atmosphere, wherein the oxidation atmosphere is 10% water vapor, 10% CO 2 , 5% O 2 , and the remaining components are N 2 , the reducing atmosphere is 10% water vapor, 10% CO 2 , 10% CO, the rest is N 2 , air velocity is 30,000h -1 , the oscillation frequency was 10 Hz, the aging temperature was 1000° C., and the aging time was 18 h, and the degraded catalyst sample S2 was prepared.

Embodiment 3

[0050] This example is used to illustrate the method disclosed in the present invention.

[0051] Place the catalyst A in the concentration of 0.003mol / L H 3 PO 4 0.1h in the solution, and then the catalyst was taken out, placed in an oven, and dried at a temperature of 110°C for 3h. Then calcined at 550°C for 6h.

[0052] The catalyst obtained from the above treatment was placed in a quartz tube reactor and heated to 1050 °C to contain 30 ppm SO 2 The air is used as the carrier gas, the space velocity is 50,000h -1 , treated for 12h to obtain the degraded catalyst sample S3.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com