Low-crack-sensitivity steel plate with yield strength of 960MPa and manufacturing method of low-crack-sensitivity steel plate

A technology of yield strength and manufacturing method, which is applied in the field of iron and steel metallurgy, can solve the problems of uneven steel plate head and tail, horizontal and vertical properties, long quenching and tempering process, and large amount of alloy addition, so as to achieve short manufacturing process and excellent comprehensive performance , the effect of low alloy content

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

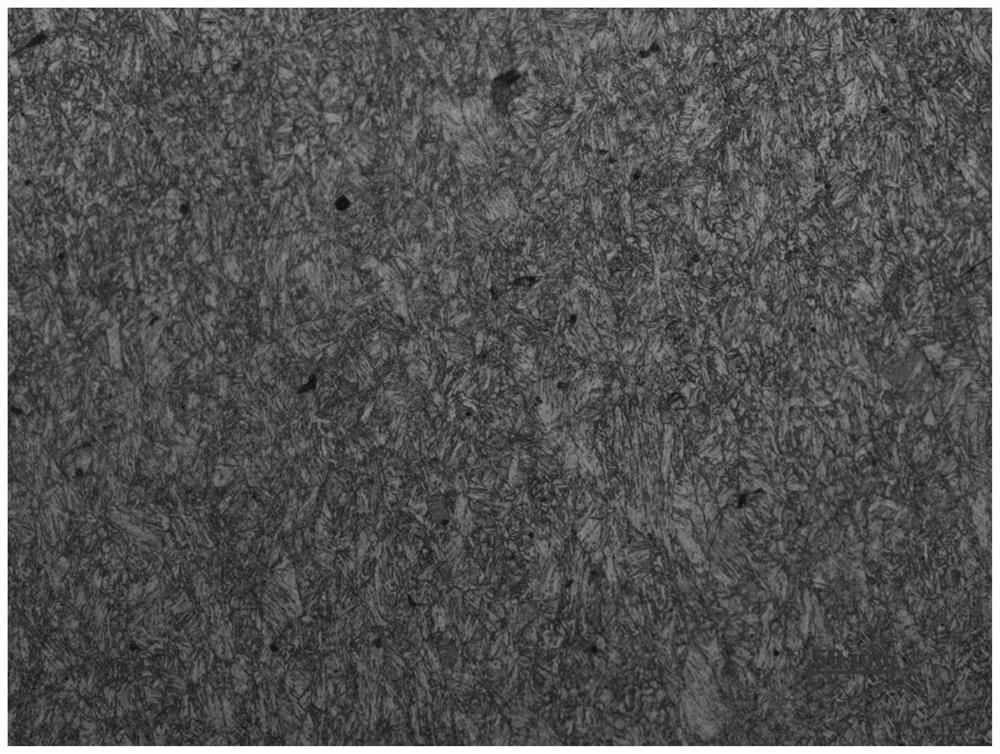

[0034] The present invention will be further described in detail below with reference to the embodiments of the accompanying drawings.

[0035] The production process flow of the yield strength 960MPa grade low-crack sensitivity steel plate of the present invention is: electric furnace or converter steelmaking->LF refining->VD or RH high vacuum degassing->continuous casting->heating rolling->on-line quenching- >tempering

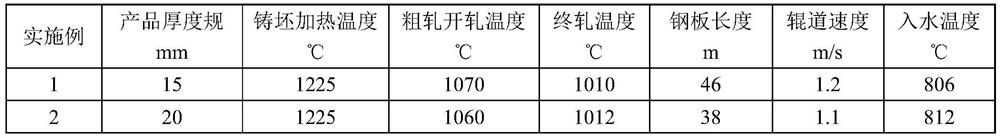

[0036] The production method of the wear-resistant steel plate of the embodiment of the present invention 1-2 comprises the following steps:

[0037] (1) Smelting: It is smelted by electric furnace or converter, and then sent to LF refining furnace for refining, and subjected to RH vacuum treatment. After the molten steel is degassed, a trace amount of Ca treatment is performed. The chemical composition control of molten steel is shown in Table 1.

[0038] (2) Continuous casting: Cast the smelted molten steel into a continuous casting billet with a thickn...

PUM

| Property | Measurement | Unit |

|---|---|---|

| yield strength | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| yield strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com