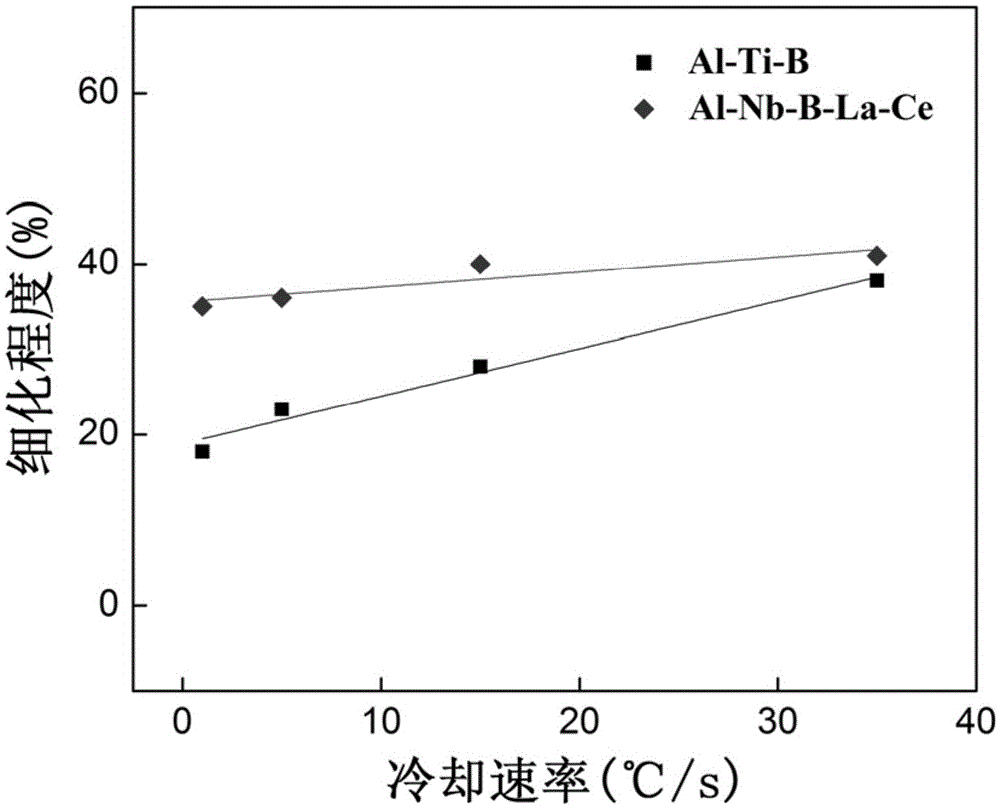

Low-cooling-rate-sensitivity high-nucleation-ability AlNbBRE grain refiner for cast aluminum alloy and preparation method thereof

A grain refiner and a technology for casting aluminum alloys, which are applied in the field of refiners for casting aluminum alloys, can solve the problems of high sensitivity to cooling rate, and achieve low sensitivity to cooling rate, improve metamorphic effect and refinement effect. excellent effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0063] Al-2Nb-B-0.4La-0.6Ce grain refiner and its preparation method.

[0064] Step one, ingredients;

[0065] Make the Al-2Nb-B-0.4La-0.6Ce target composition of 100 weight parts, the required raw material is the Al-10Nb of 20 weight parts, the purity of 1 weight part be 99.5% potassium fluoroborate (KBF 4 ) powder, 0.4 parts by weight of metal lanthanum (La) with a purity of 99.0%, 0.6 parts by weight of metal cerium (Ce) with a purity of 99.0%, and the remainder of a block of Al with a size of 5cm×5cm.

[0066] Step 2, preparation of auxiliary materials for smelting

[0067] Use a dust collector to clean the graphite crucible, mold, inner wall of the bell jar, and skimming spoon, preheat it at 220°C for 3 hours, and evenly brush the protective paint on the surface of the mold, bell jar, and skimming spoon to avoid it from being mixed with When the molten aluminum contacts, impurities such as iron are brought into the molten aluminum,

[0068] In the present invention, th...

Embodiment 2

[0081] Al-4Nb-0.8B-0.5La-0.5Y grain refiner and its preparation method.

[0082] Step one, ingredients;

[0083] Make the Al-4Nb-0.8B-0.5La-0.5Y target composition of 100 weight parts, the required raw material is the Al-10Nb of 40 weight parts, the purity of 0.8 weight part be 99.5% potassium fluoroborate (KBF 4 ) powder, 5 parts by weight of an Al-10La master alloy block with a size of 3×3 cm, 5 parts by weight of an Al-10Y master alloy block with a size of 3×3 cm, and the remainder of an Al block with a size of 5×5 cm.

[0084] Step 2, preparation of auxiliary materials for smelting

[0085] Use a dust collector to clean the graphite crucible, mold, inner wall of the bell jar, and skimming spoon, preheat it at 300°C for 2 hours, and evenly brush protective paint on the surface of the mold, bell jar, and skimming spoon to avoid it When the molten aluminum contacts, impurities such as iron are brought into the molten aluminum,

[0086] In the present invention, there are 2...

Embodiment 3

[0100] Al-3Nb-0.6B-0.6La-0.4Ce grain refiner and its preparation method.

[0101] Step one, ingredients;

[0102] To make 100 parts by weight of Al-3Nb-0.6B-0.6La-0.4Ce target composition, the required raw materials are 30 parts by weight of Al-10Nb, 12 parts by weight of Al-5B master alloy block (size is 3 * 3cm) , 0.6 parts by weight of metal lanthanum (La) with a purity of 99.0%, 0.4 parts by weight of metal cerium (Ce) with a purity of 99.0%, and the rest of Al blocks with a size of 5×5 cm.

[0103] Step 2, preparation of smelting auxiliary materials

[0104] Use a dust collector to clean the graphite crucible, mold, inner wall of the bell jar, and skimming spoon, preheat it at 280°C for 2.5 hours, and evenly brush protective paint on the surface of the mold, bell jar, and skimming spoon to avoid When in contact with molten aluminum, impurities such as iron are brought into the molten aluminum,

[0105] In the present invention, there are 22% by weight of chalk powder, ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com