Rigidity-toughness balanced polypropylene

A polypropylene, balanced technology, applied in the field of polypropylene materials and its preparation, can solve the problems of product longitudinal and transverse properties, shrinkage differences, etc., to achieve the effect of reducing processing costs, reducing the amount of toughening agent, and improving the degree of dispersion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

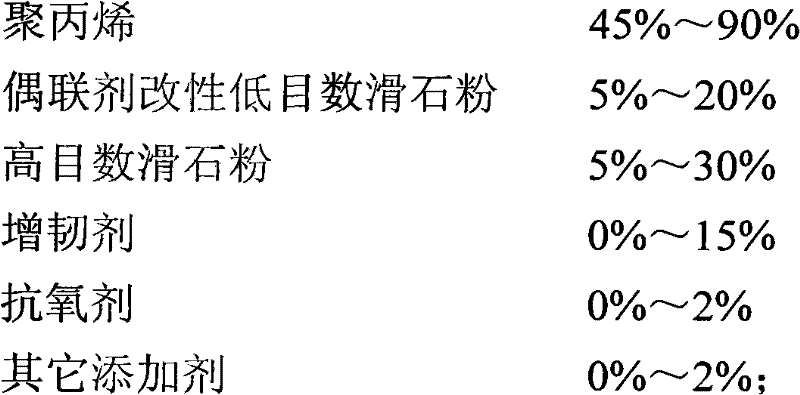

Method used

Image

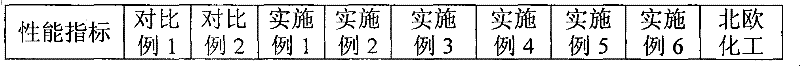

Examples

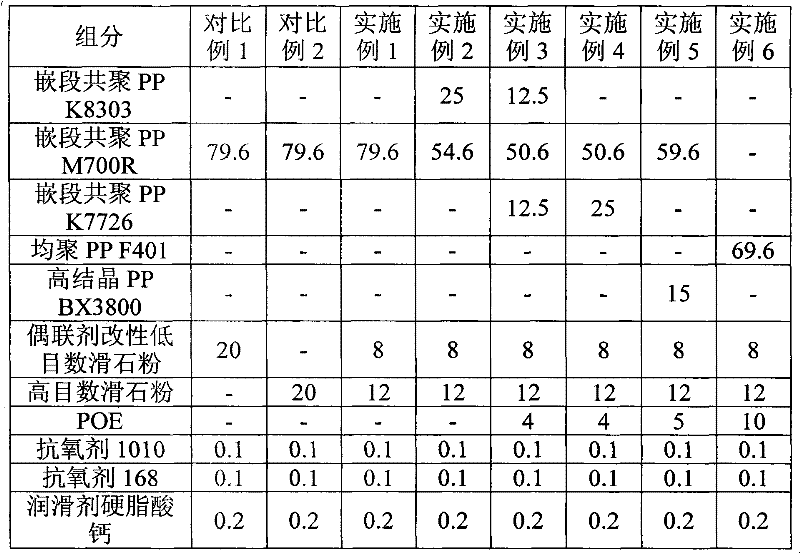

Embodiment 1

[0031] Surface treatment of low-mesh talc powder: Dilute 1kg of silane coupling agent KH550 (γ-aminopropyltriethoxysilane) with 1 bottle of 500mL absolute ethanol, mix with 100kg of 400-mesh low-mesh talc powder Mix evenly in the machine to prepare coupling agent-modified low-mesh talc powder. Put 8Kg coupling agent modified low-mesh talcum powder into the side feeding hopper of the twin-screw extruder.

[0032] Take by weighing 79.6Kg block copolymerization PP M700R (Shanghai Petrochemical), 12Kg mesh number is 3000 mesh high-mesh talcum powder, 0.1Kg antioxidant 1010, 0.1Kg antioxidant 168 and 0.2Kg lubricating oil by weight ratio in Table 1 Add calcium stearate, pour it into the mixer, make the material mix evenly, and put it into the main feeding hopper of the twin-screw extruder.

[0033] The barrel of the twin-screw extruder is a ten-section barrel, the first section of the barrel is connected to the main feeding device, the fifth section of the barrel is exhausted, the...

Embodiment 2

[0039] Surface treatment of low-mesh talc powder: Dilute 1kg of silane coupling agent KH550 (γ-aminopropyltriethoxysilane) with 1 bottle of 500mL absolute ethanol, mix with 100kg of low-mesh talc powder with a mesh of 1250 Mix evenly in the machine to prepare coupling agent-modified low-mesh talc powder. Put 8Kg coupling agent modified low-mesh talcum powder into the side feeding hopper of the twin-screw extruder.

[0040] Weigh 25Kg block copolymerized PP K8303 (Yanshan Petrochemical), 54.6Kg block copolymerized PP M700R (Shanghai Petrochemical), 12Kg of 5000 mesh high-mesh talcum powder, 0.1Kg antioxidant 1010 according to the weight ratio in Table 1 , 0.1Kg antioxidant 168 and 0.2Kg lubricant calcium stearate, pour into mixer, mix homogeneously, put into twin-screw extruder main feeding hopper.

[0041] Other operations were the same as in Example 1 to obtain rigid-tough balance polypropylene.

[0042] Test method is the same as embodiment 1.

Embodiment 3

[0044] Surface treatment of low-mesh talc powder: Dilute 1kg of silane coupling agent KH550 (γ-aminopropyltriethoxysilane) with 1 bottle of 500mL absolute ethanol, mix with 100kg of low-mesh talc powder with a mesh of 1250 Mix evenly in the machine to prepare coupling agent-modified low-mesh talc powder. Put 8Kg coupling agent modified low-mesh talcum powder into the side feeding hopper of the twin-screw extruder.

[0045] Weigh 12.5Kg of block copolymerized PP K8303 (Yanshan Petrochemical), 50.6Kg of block copolymerized PP M700R (Shanghai Petrochemical), 12.5Kg of block copolymerized PP K7726 (Yanshan Petrochemical) and 12Kg of 5000 mesh according to the weight ratio in Table 1. Purpose high-mesh talcum powder, 4Kg toughening agent POE (density is 0.86g / cm 3 , 190 ℃ × 2.16kg test conditions under the melt flow rate of 0.5g / 10min), 0.1Kg antioxidant 1010, 0.1Kg antioxidant 168 and 0.2Kg lubricant calcium stearate, pour into the mixer, make the material Mix well and put into ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melt flow index | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| melt flow index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com