Method for accelerating crystallization of polylactic acid resin

A polylactic acid resin and crystallization technology, which is applied in the field of accelerated crystallization of polylactic acid resin, can solve the problems of difficulty in achieving uniform dispersion, affecting the overall performance of products, and large differences in chemical structure, so as to speed up the crystallization speed, improve the nucleation effect, and improve Effect of Machinability and Thermal Properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0019] The preparation method of the semi-crystalline polylactic acid resin is not particularly limited, for example, polylactic acid can be obtained by ring-opening polymerization of L, L-type, D, L-type lactide, L-type, D-type or racemic lactic acid Polylactic acid is obtained by direct polycondensation, and polylactic acid is obtained by three-dimensional crosslinking of polylactic acid by light, heat, radiation, and crosslinking agents. Semi-crystalline polylactic acid resin can also use known inorganic fillers, fillers, and flame retardants. In addition to the above-mentioned components, well-known plasticizers, heat stabilizers, light stabilizers, antioxidants, and anti-hydrolysis agents can also be used together. , internal and external lubricants, impact modifiers, antistatic agents, colorants, release agents, foaming agents, pigments, antibacterial and anti-enzyme agents, coupling agents, other fillers, other nucleating agents, and general synthetic resins Auxiliaries...

Embodiment 1

[0022] Embodiment 1: the preparation of pure polylactic acid spline

[0023] 100 parts of vacuum-dried semi-crystalline poly-L-lactic acid (Shimazu company 9020 grade, containing about 1.5% of D configuration, weight average molecular weight of 186,000) were extruded in a twin-screw extruder at 190 °C, drawn into strands, and Cool in the air and granulate.

[0024] Test of crystallization speed: use DSC test, nitrogen atmosphere. In the non-isothermal DSC test, the sample was heated from room temperature to 190 °C at 100 °C / min, kept for 2 min to eliminate thermal history, cooled to 30 °C at 10 °C / min, kept at 30 °C for 2 min, and then heated at 10 °C / min to 190°C. In the isothermal DSC analysis, the sample was heated from room temperature to 190 °C at 100 °C / min, kept for 2 min to eliminate thermal history, rapidly cooled to 120 °C at 100 °C / min, kept for 60 min, and then raised to 10 °C / min 190°C.

[0025] The crystallinity during cooling at 10 °C / min was calculated fro...

Embodiment 2

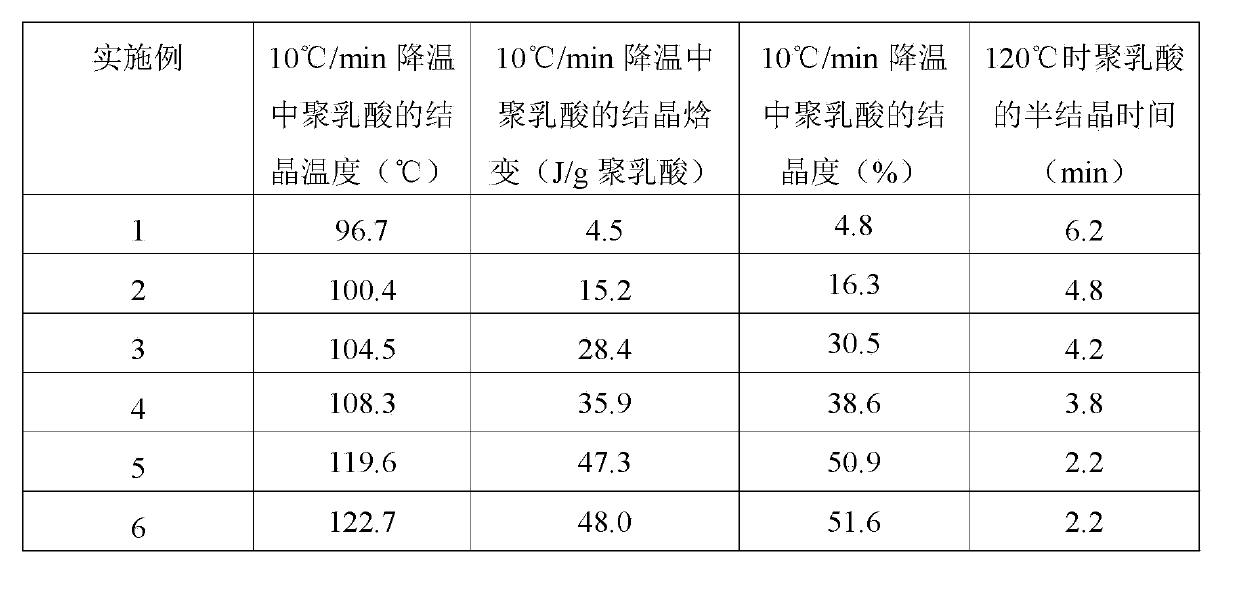

[0027] Vacuum-dried semi-crystalline poly-L-lactic acid (Shimazu company's 9020 grade, containing about 1.5% of the D configuration, with a weight average molecular weight of 186,000) 99 parts and PVDF (Wu Yu Chemical Company, KF850 grade) 1 part at 190 °C Extrude in a twin-screw extruder, draw strands, cool in air, and pelletize. The calculated crystallization kinetics and thermal performance parameters are shown in Table 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com