High-nickel type lithium Ni-Co manganate precursor with specific morphology and preparation method thereof

A technology of nickel cobalt lithium manganate and precursor, which is applied in the field of nickel cobalt lithium manganate precursor and its preparation, can solve the problem that the morphology sphericity of high nickel precursor has not been fully explained, and the key process parameters have not been paid enough attention to. The problems of limited primary particle morphology, etc., can enhance the nucleation effect, solve the nucleation difficulties, and improve the sphericity.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

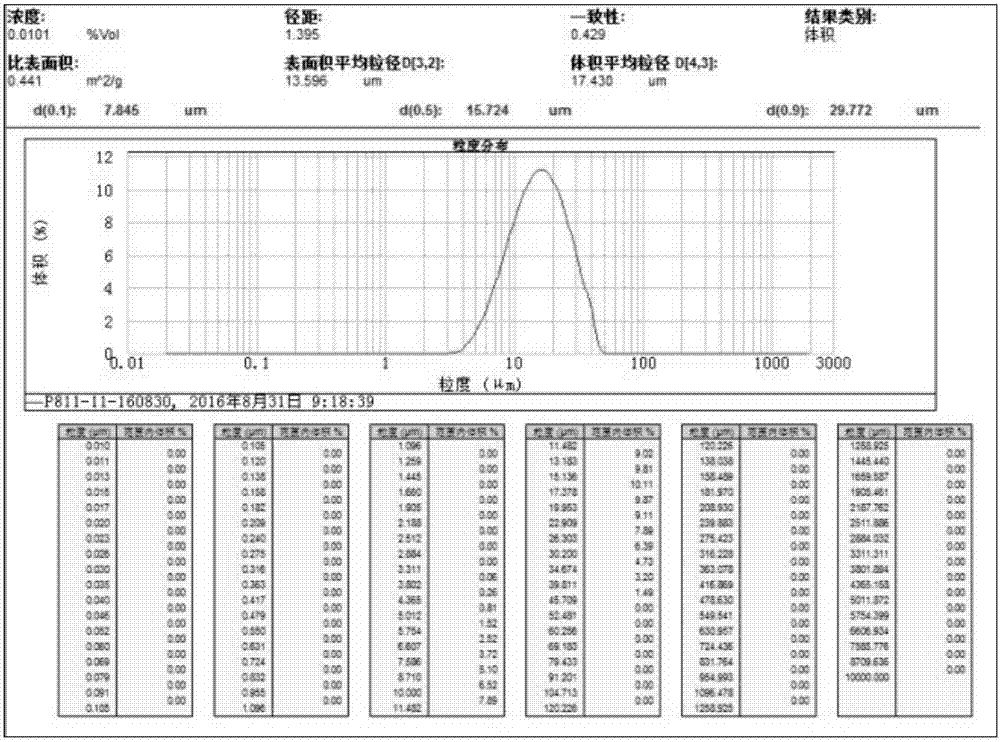

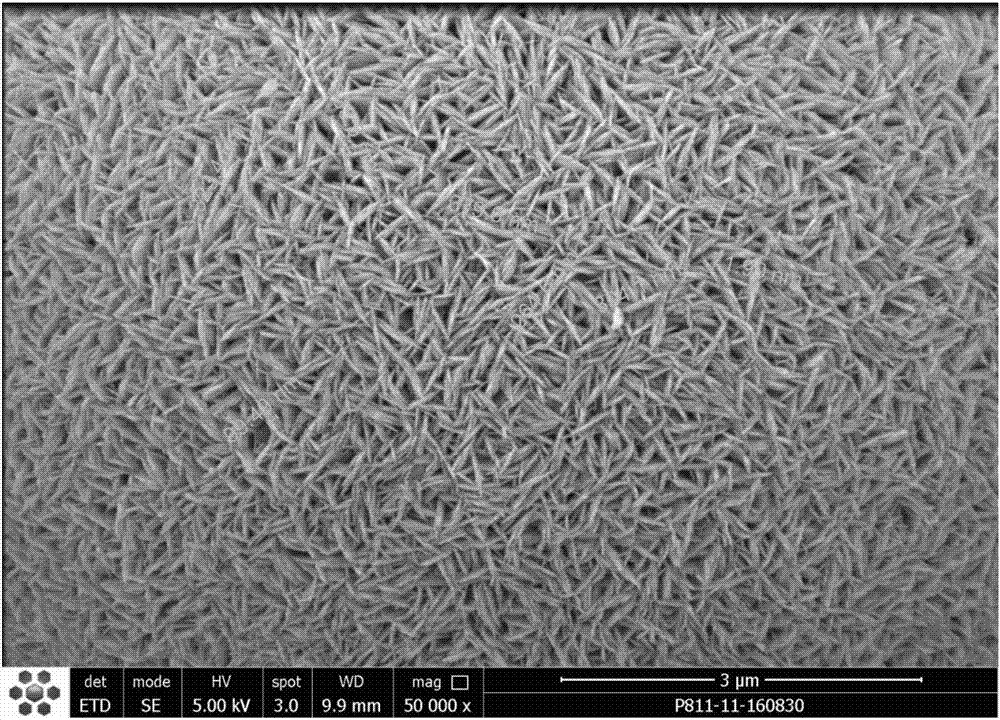

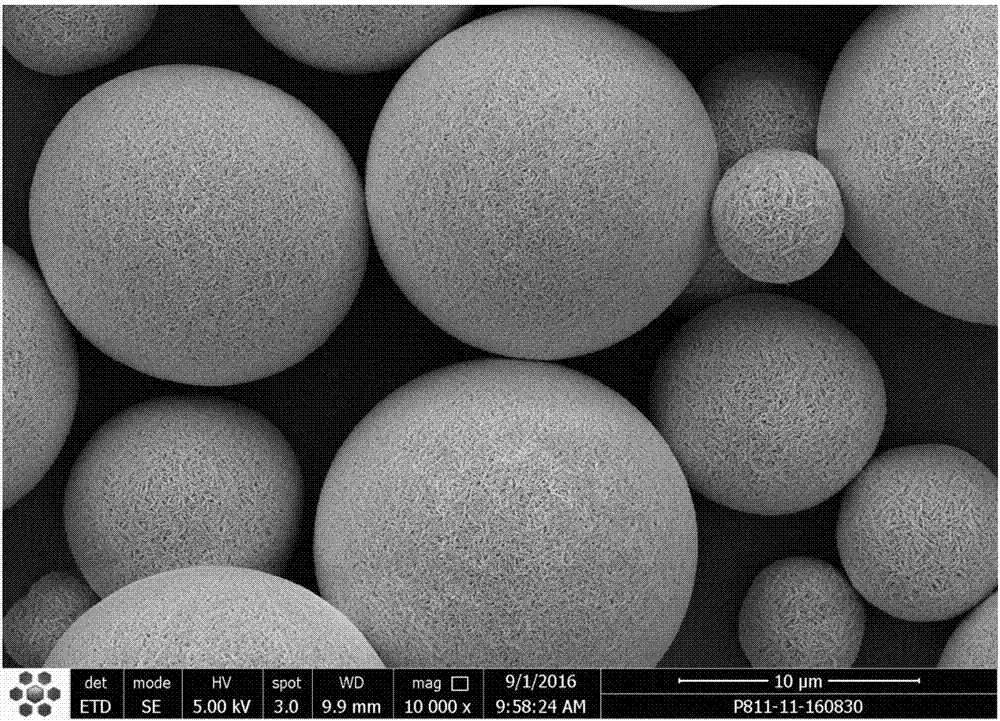

[0061] a kind of like Figure 1-Figure 7 The high-nickel type nickel-cobalt lithium manganese oxide precursor with specific morphology shown in the present invention, the molecular formula of the high-nickel type nickel-cobalt lithium manganese oxide precursor is Ni 0.8 co 0.1 mn 0.1 (OH) 2 ; The average primary particle size of the high-nickel type nickel-cobalt lithium manganate precursor is 300-400nm; the particle size of the secondary particle aggregate is D5=6.56μm, D10=7.84μm, D50=15.72μm, D90=29.7μm , D100=45.44μm (see figure 1 ). The 001 crystal plane half-peak width F001=0.534 of this high-nickel type nickel-cobalt lithium manganese oxide precursor (see Figure 7 ),Such as Figure 6As shown, the grain profile shows that the crystal internal growth direction is linear radial. The tap density of the high nickel nickel cobalt lithium manganate precursor is 2.15g / cm 3 , the specific surface area is 11.1m 2 / g, bulk density 1.98g / cm 3 , S content = 0.16%. Depend...

Embodiment 2

[0080] a kind of like Figure 15-Figure 20 The high-nickel type nickel-cobalt lithium manganese oxide precursor with specific morphology shown in the present invention, the molecular formula of the high-nickel type nickel-cobalt lithium manganese oxide precursor is Ni 0.8 co 0.1 mn 0.1 (OH) 2 ; The primary particle average particle size of this high-nickel type nickel cobalt lithium manganate precursor is 300-400nm; The particle size of secondary particle agglomerates, D10=8.28 μ m, D50=12.19 μ m, D90=17.91 μ m (see Figure 15 ). The 001 crystal plane half-peak width F001=0.546 of this high-nickel type nickel-cobalt lithium manganese oxide precursor (see Figure 21 );Such as Figure 20 As shown, the grain profile shows that the crystal internal growth direction is linear radial. The tap density of the high nickel nickel cobalt lithium manganese oxide precursor is 2.12g / cm 3 , the specific surface area is 10.69m 2 / g, bulk density 1.83g / cm 3 , S content = 0.17%. Depen...

Embodiment 3

[0090] a kind of like Figure 22-Figure 27 The high-nickel type nickel-cobalt lithium manganese oxide precursor with specific morphology shown in the present invention, the molecular formula of the high-nickel type nickel-cobalt lithium manganese oxide precursor is Ni 0.8 co 0.1 mn 0.1 (OH) 2 ; The primary particle average particle size of this nickel-cobalt lithium manganate precursor is 400-500nm; the particle size D10=7.25 μm of the secondary particle aggregate, D50=11.37 μm, D90=17.69 μm (see Figure 22 ). The 001 crystal plane half-peak width F001=0.534 of this high-nickel type nickel-cobalt lithium manganese oxide precursor (see Figure 28 );Such as Figure 27 As shown, the grain profile shows that the crystal internal growth direction is linear radial. The tap density of the high nickel nickel cobalt lithium manganese oxide precursor is 2.08g / cm 3 , the specific surface area is 10.2m 2 / g, bulk density 1.94g / cm 3 , S content = 0.12%. Depend on Figure 23-Figu...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Granularity | aaaaa | aaaaa |

| Tap density | aaaaa | aaaaa |

| Specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com