Ceramic channel used in cryogenic liquid helium environment and preparation method thereof

A ceramic and channel technology, which is applied in the field of high-performance ceramic preparation, can solve the problems of long-term service performance that cannot meet the stable operation of the device, achieve the effects of fine grain size, improved radiation resistance performance, and overcome the deterioration of air tightness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The experimental methods used in the following examples are conventional methods unless otherwise specified.

[0028] The materials and reagents used in the following examples can be obtained from commercial sources unless otherwise specified.

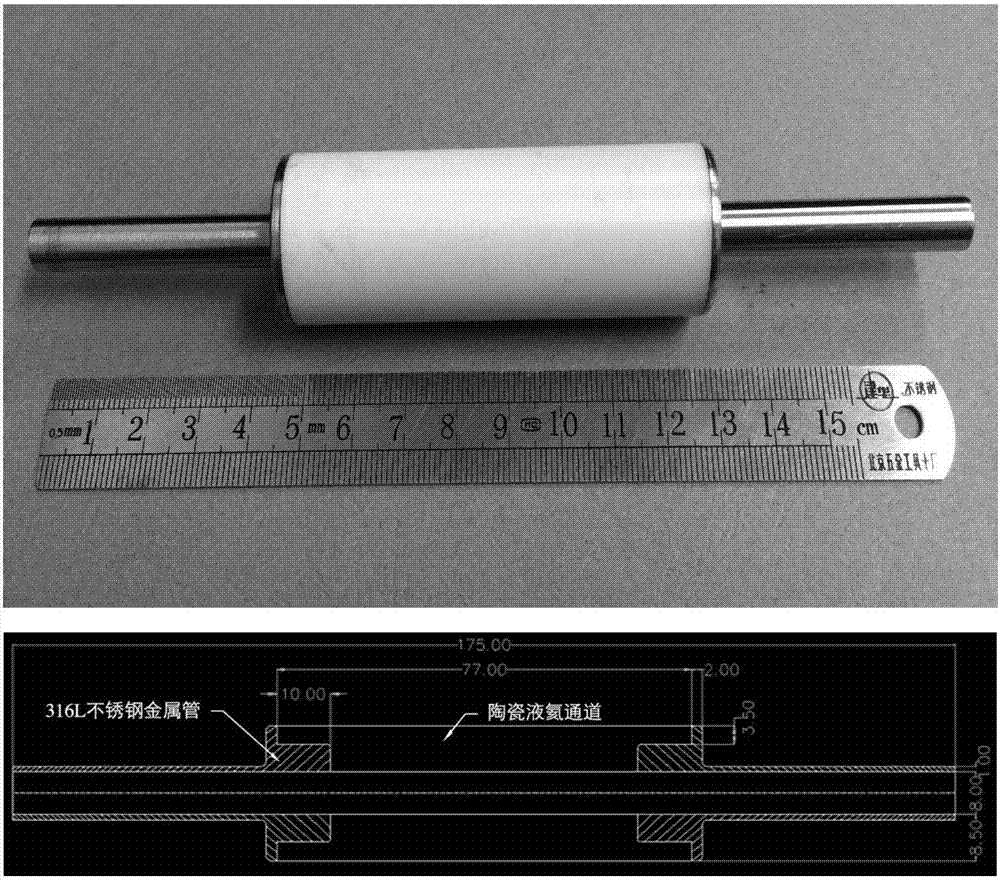

[0029] Such as figure 1 As shown, the ceramic material insulation channel of the present invention has an inner diameter of 8 mm and an outer diameter of 25 mm. There is a groove with an inner diameter of 18mm at both ends of the ceramic channel, which is convenient for welding with 316L stainless steel seamless pipe. Concretely prepare according to the following steps:

[0030] Step 1: Mixing of ceramic powder.

[0031] Accurately weigh ceramic powder and organic solvent, and use ball milling method to mix the weighed ceramic powder and organic solvent evenly to obtain liquid slurry. In the mixture, the mass percentage of ceramic powder is 98%, and the mass percentage of organic solvent is 2%; wherein, the ceramic powder (p...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com