0.5mm sensitivity double-skip-bucket type rainfall sensor

A rain sensor and tipping bucket technology, which is applied in the field of meteorological observation devices, can solve the problems of affecting the reliability of measurement results, the increase of sensor measurement error, and the distortion of indication records, etc., so as to achieve easy removal and replacement, simplify design, and reduce surface impedance Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

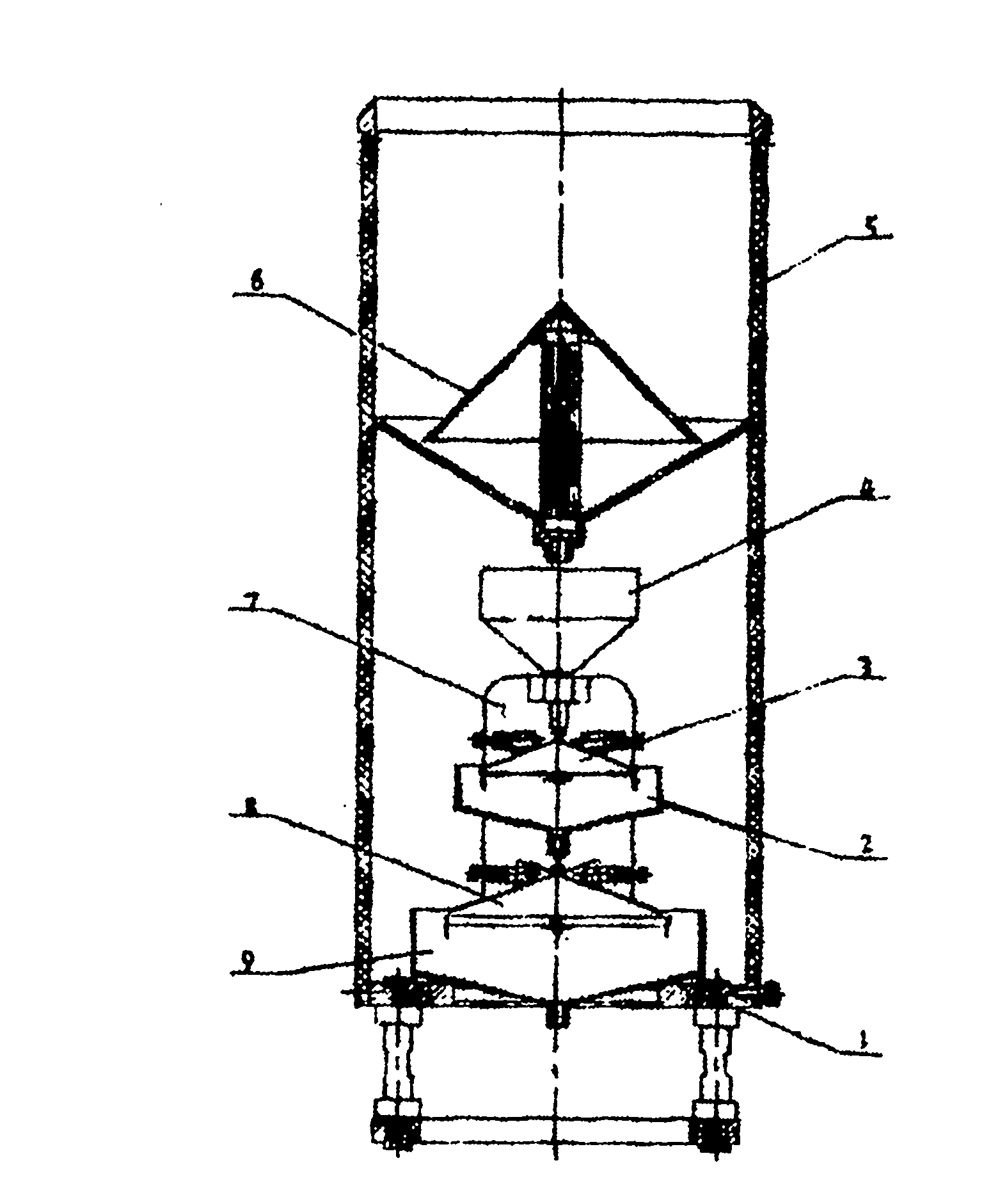

[0033] Such as figure 1 Shown is a 0.5mm sensory double tipping bucket type rain sensor, a cylindrical rain receiver 5 with a base 1 at the bottom of the cylindrical rain receiver, which is installed sequentially from bottom to top on the base in the rain receiver. There are lower floor water collector 9, large tipping bucket 8, upper layer water collector 2, small tipping bucket 3, funnel 4, each water collector is installed on vertical plate 7, and anti-blocking device 6 is arranged above the funnel.

[0034] Such as Figure 4 The shown anti-blocking device has an umbrella-shaped anti-blocking cover 4.2, and there is a columnar filter screen 4.1 in the middle of the bottom of the anti-blocking cover.

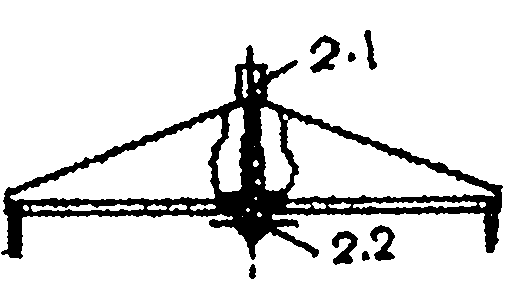

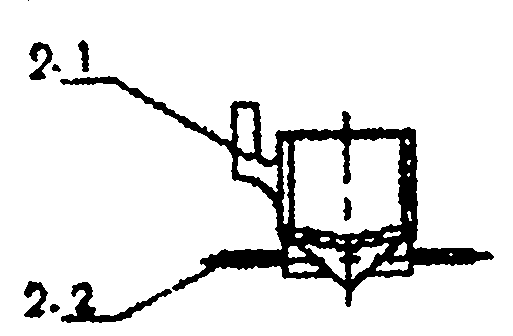

[0035] Such as Figure 2.1 , 2.2 The tipping bucket of the small dumping bucket shown in 2.3 is a rectangular box-shaped dumping bucket. There is a dumping bucket shaft 2.2 below the middle of the rectangular box of the dumping bucket, and a magnetic steel 2.1 is installed ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com