Patents

Literature

38results about How to "Long protection period" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Solid corrosion and scale inhibitor for oil field

InactiveCN101805597ALow cost of corrosion and scale inhibitionReduce filling operationsDrilling compositionBorehole/well accessoriesPolyethylene glycolTricarboxylic acid

The invention discloses a solid corrosion and scale inhibitor for an oil field, which relates to the technical field of chemical medicine reagents used for the oil field. The solid corrosion and scale inhibitor comprises the following ingredients: 2-phosphonic acid butane 1, 2, 4-tricarboxylic acid PBTCA, polyethyleneglycol, sodium hexametahposphate, span-60 and stearic acid, wherein each ingredient accounts for the mass percent of the sum of all the ingredients as follow: 30 percent to 40 percent of 2-phosphonic acid butane 1, 2, 4-tricarboxylic acid PBTCA, 10 percent to 15 percent of polyethyleneglycol, 10 percent to 15 percent of sodium hexametahposphate, 15 to 25 percent of span-60 and 20 percent to 30 percent of stearic acid. The invention is particularly suitable for well tubes of oil-gas wells with server corrosion and scale conditions, and has good corrosion and scale inhibition effects on underground pipe posts and equipment.

Owner:CHINA NAT PETROLEUM CORP CHUANQING DRILLING ENG CO LTD

A kind of nodular cast iron pipe with waterproof protective layer and its production process

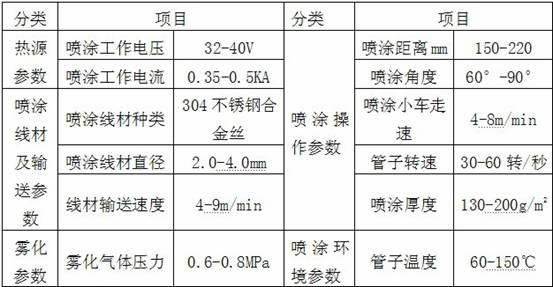

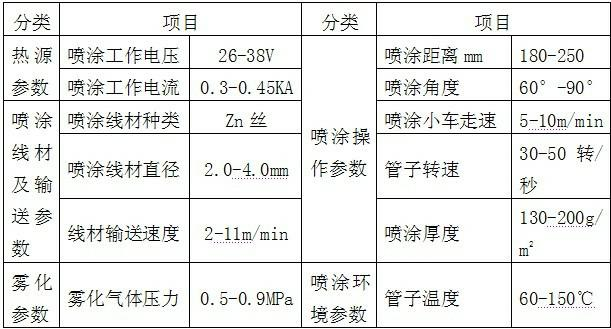

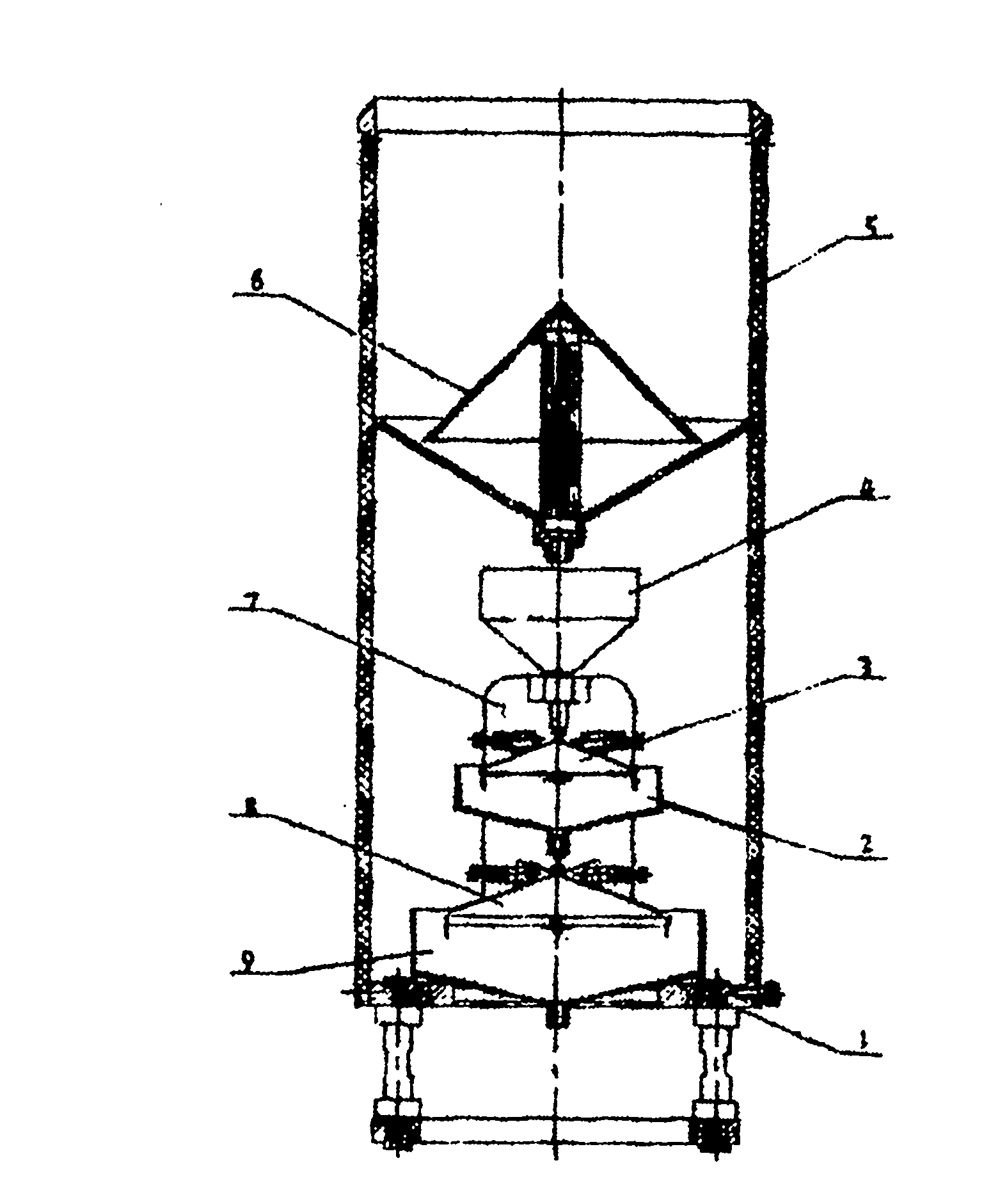

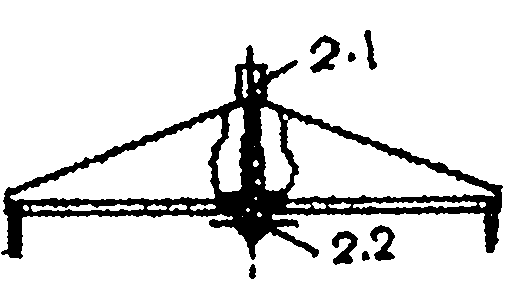

ActiveCN102278568AImprove corrosion resistanceNeat appearanceCorrosion preventionPipe protection against corrosion/incrustationWear resistanceZinc

The invention discloses a ductile cast iron pipe with a waterproof protective layer and a production process thereof. The method comprises the following steps of: (1) performing surface treatment on the ductile cast iron pipe to remove surface oxides thereof; (2) spraying a zinc protective layer; (3) spraying a stainless steel protective layer; and (4) coating an enclosed corrosion-resistant protective layer. The invention has the advantages that: the zinc protective layer, the stainless steel protective layer and the enclosed corrosion-resistant protective layer are sequentially sprayed at the periphery of the ductile cast iron pipe through an arc spraying method, and a sacrificial anode protection function of the zinc protective layer, the wear resistance and corrosion resistance of thestainless steel coating and the hole-sealing corrosion inhibition performance of the enclosed coating can be cooperatively exerted, so that the ductile cast iron pipe is well protected. The ductile cast iron pipe with the coating structure has high corrosion resistance in a hydraulic environment, the waterproof protective layer has a neat appearance, covers uniformly and densely, has long protection period, high corrosion resistance and high damage resistance, secondary excavation construction is not needed, and the life cycle cost of a project is obviously reduced.

Owner:XINXING DUCTILE IRON PIPES CO LTD

0.5mm sensitivity double-skip-bucket type rainfall sensor

InactiveCN102116878AImprove wash resistanceHigh surface hardnessRainfall/precipitation gaugesICT adaptationHardnessEngineering

The invention discloses a 0.5mm sensitivity double-skip-bucket type rainfall sensor. The bottom of a cylindrical rain container is provided with a base; the base of the rain container is provided with a lower water collector, a large skip bucket, an upper water collector, a small skip bucket and a funnel from bottom to top in turn; each water collector is arranged on a vertical plate; and an anti-blocking device is arranged above the funnel. The upper small skip bucket is designed to be a symmetric slope container, the lower large skip bucket is designed to be a labyrinthic container, the centers of gravity of a left bucket chamber and a right bucket chamber of each skip bucket are symmetric, and the skip bucket swings in a balanced way, so that stable performance is guaranteed during impact of heavy rains, and the sensor has high measuring accuracy. A hydrophobic layer has high flushing resistance and high surface hardness, and is environment-friendly and safe. Error is not influenced by raininess, and instant rainfall can be measured. Stable work and accurate measuring data of the rainfall sensor are guaranteed. Failed components can be easily approached during maintenance, and the failed components are easy to disassemble and replace, so that the manufacturing cost and the field maintenance cost are reduced.

Owner:天津华云天仪特种气象探测技术有限公司

Sun-proof and antibacterial textile fabric

InactiveCN107881625ALong lasting effectGood antibacterial and UV resistanceWoven fabricsYarnWeather resistanceWeft yarn

The invention discloses a sun-proof and antibacterial textile fabric which is formed by vertically interweaving warp yarns and weft yarns. The warp yarns are made from, by mass, 42-45 parts of polyester and acrylic composite fiber, 3-7 parts of alpha-methyl styrene, 0.8-1.6 parts of cross-linking agent and 1-3 parts of chitosan. The weft yarns are made from, by mass, 60-70 parts of polylactic acidfiber, 16-18 parts of plant fiber, 2-4.8 parts of titanium dioxide, 1-3 parts of vermiculite power and 10-30 parts of polyvinyl alcohol. The sun-proof and antibacterial textile fabric is prepared through a reasonable formula, crosslink bonding of the raw materials is modified, the effect durability is strong, the made wrap and weft yarns have good antibacterial and anti-ultraviolet properties, the weather resistance is good, the breathability, oxygen permeability and hygroscopicity of the textile fabric are good, biodegradable fiber is adopted and matched with the plant fiber, and the sun-proof and antibacterial textile fabric is green, environmentally friendly, calms the mind, reposes a user and is high in comfort level and especially suitable for wearing when it is burning hot and sunlight is strong in summer.

Owner:HEFEI NORMAL UNIV

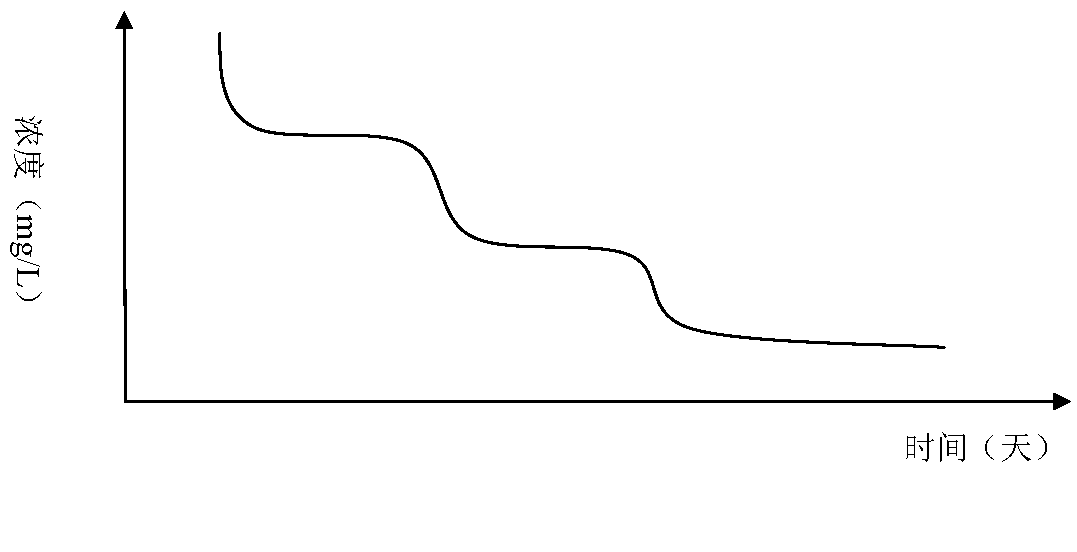

Echelon releasing method for underground solid anticorrosion and antiscale agents

ActiveCN103075132ALong protection periodDosing saves time and effortDrilling compositionBorehole/well accessoriesOil wellChemistry

The invention provides an echelon releasing method for underground solid anticorrosion and antiscale agents, and the method comprises the following steps of step 1: charging imidazoline inhibitor with a dissolving speed of 0.12g / cm<2>*h, imidazoline inhibitor with a dissolving speed of 0.01g / cm<2>*h, organic phosphonate antiscale agent and clay or kaolin into a tablet press according to a proportion of 0.4: 1.6: 1: 2 to a prepare solid anticorrosion and antiscale agent 1; step 2: charging the imidazoline inhibitor with the dissolving speed of 0.12g / cm<2>*h, the imidazoline inhibitor with the dissolving speed of 0.05g / cm<2>*h, organic phosphonate antiscale agent and clay or kaolin into a tablet press according to a proportion of 0.4: 1.6: 1: 2 to prepare a solid anticorrosion and antiscale agent 2; selecting the solid anticorrosion and antiscale agent 1 when the underground temperature is more than 50DEG C, and selecting the solid anticorrosion and antiscale agent 2 when the underground temperature is less than 50DEG C; and directly charging the solid anticorrosion and antiscale agents before a tubular post is arranged or charging the solid anticorrosion and antiscale agent into a sieve tube, which is hung under a pump, to charge the solid anticorrosion and antiscale agent into an oil well.

Owner:XINJIANG KELI NEW TECH DEV

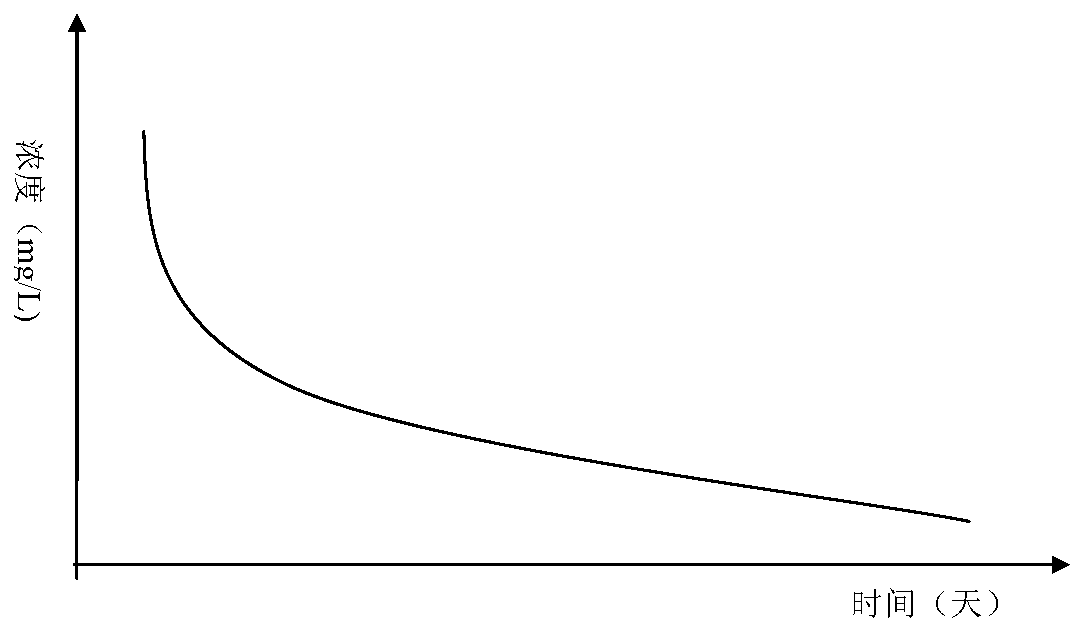

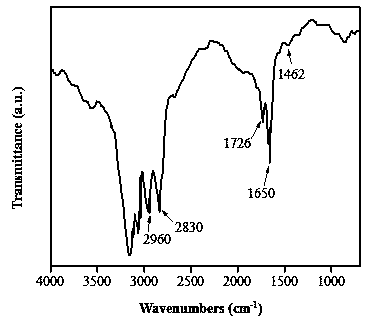

Environment-friendly slow-release polymer scale inhibitor and preparation method thereof

ActiveCN107304078ABiodegradableWon't happenWaste water treatment from quariesWater treatment compoundsOil fieldRelease time

The invention discloses an environment-friendly slow-release polymer scale inhibitor, which is good in scale inhibition and slow release effects. The dosage of the scale inhibitor which needs to be added within a maintenance cycle can be estimated in advance according to the actual production condition of an oil well; the scale inhibitor is put into a sieve tube at the lower end of an oil-well pump of the oil well in regular repair and maintenance processes of an oil-well pipeline and a gathering pipeline; scale inhibition components are slowly dissolved and released to achieve the long-term scale inhibition effect through one-off addition when a produced liquid flows through the sieve tube, so that the long-term effective concentration can be maintained, the scale inhibiting ratio within the effective service cycle (about 90-120d) is greater than 85%, the effective release time can reach 90d or over, the protection period on the pipeline is long, and the production and maintenance cost of an oil field can be effectively reduced. The environment-friendly slow-release polymer scale inhibitor is nontoxic, harmless and degradable, and does not harm the formation and surrounding environment, and is environmentally friendly and suitable for popularization and application.

Owner:WUHAN UNIV OF TECH

Preparation method of solid corrosion-inhibition scale-inhibition bar used for oil field

ActiveCN101781767ASimple stepsLong protection periodDrilling compositionChemistryPolyethylene glycol

The invention discloses a preparation method of a solid corrosion-inhibition scale-inhibition bar used for an oil field, which relates to a production method of a chemical medicament used for the oil field. The preparation method comprises the following steps of: (1) mixing 30 to 40 percent of 2-phosphonobutane-1,2,4-tricarboxylic acid, 10 to 15 percent of polyethylene glycol, 10 to 15 percent of sodium hexametaphosphate, 15 to 25 percent of Span-60 and 20 to 30 percent of stearic acid evenly, wherein the percent is the mass percent of the sum of each component occupying all the components; and (2) putting all the evenly mixed components into a bar type mold, pressing into a bar type by using a press machine and forming a finished product, wherein the pressure applied by the press machine is 15 to 20 tons. The method has the advantages of simple preparation process, even mixing of the components, trouble saving and labor saving, so that the method is suitable for mass and industrialized production and large-scale popularization and application.

Owner:BC P INC CHINA NAT PETROLEUM CORP +1

Antibacterial nano after-finish agent for knitted fabrics and preparation method thereof

InactiveCN110983755AImprove adhesionLong protection periodBiochemical fibre treatmentFiberFirming agent

The invention provides an antibacterial nano after-finish agent for knitted fabrics and a preparation method thereof. In terms of mass percentage, the antibacterial nano after-finish agent for knittedfabrics includes the following components of nano-scale antibacterial coating agent 4.5% to 7.5%, titanium dioxide hydrosol 7% to 12%, metal-loaded composite mineral powders 2% to 4. 5%, coupling agent 1% to 4%, and curing agent 1% to 4%, and the balance is water. The antibacterial nano after-finish agent for knitted fabrics has reasonable raw material selection, uses the titanium dioxide hydrosol as the jointing basis, and uses the nano-scale antibacterial coating agent and metal-loaded composite mineral powders as effective antibacterial ingredients; therefore, the overall antibacterial effect is good, the structure is uniform and stable, the film formation is good, the adhesion to the knitted fabric fiber is strong, the chemical crosslinking effect is good, and the reagent fastness issignificantly improved; and meanwhile, the antibacterial nano after-finish agent for knitted fabrics has excellent ultraviolet resistance, good sun protection effect, and fragrant and refreshing effect, and the fabric protection period is prolonged significantly.

Owner:安徽圩码网络科技有限公司

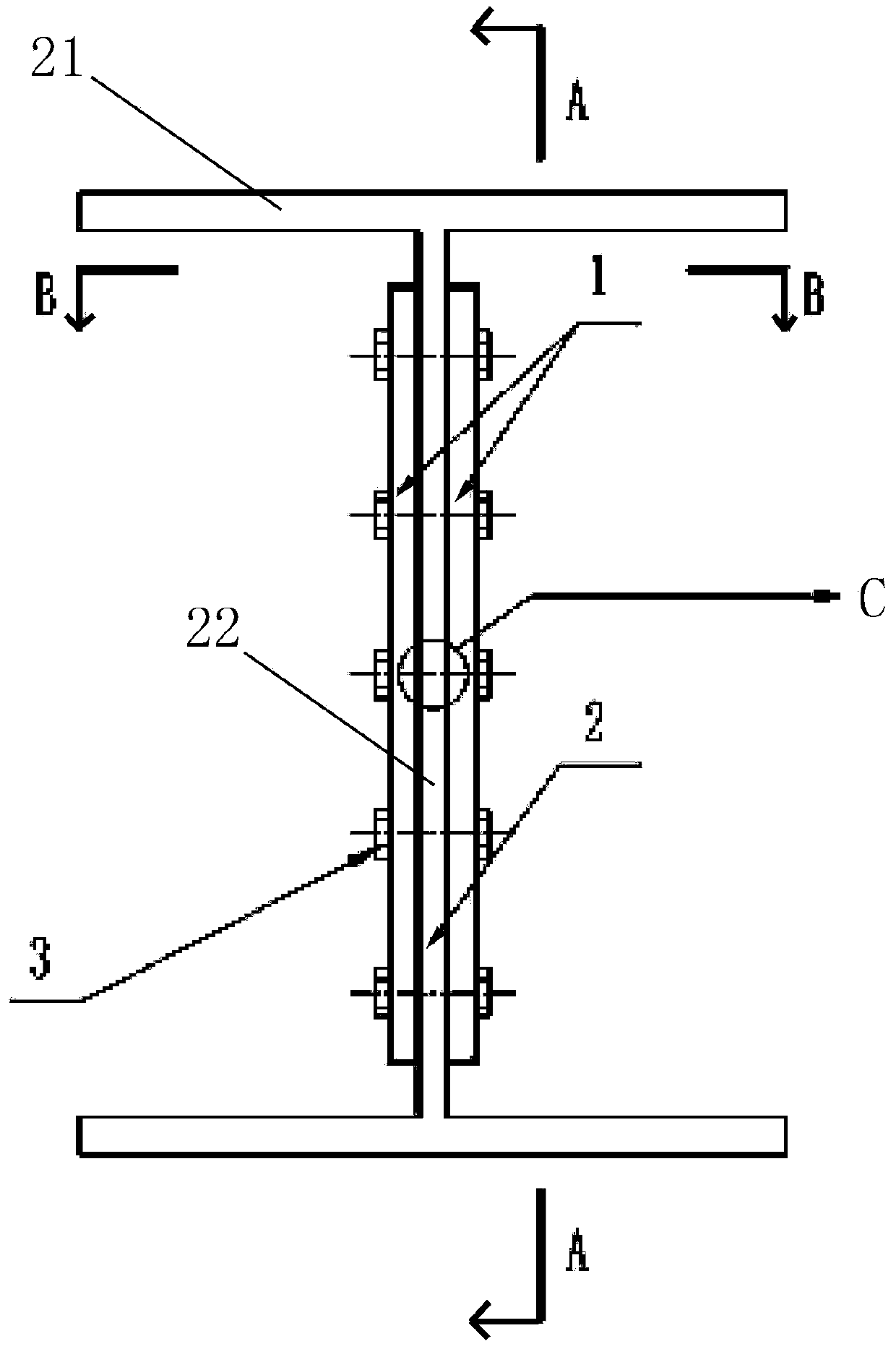

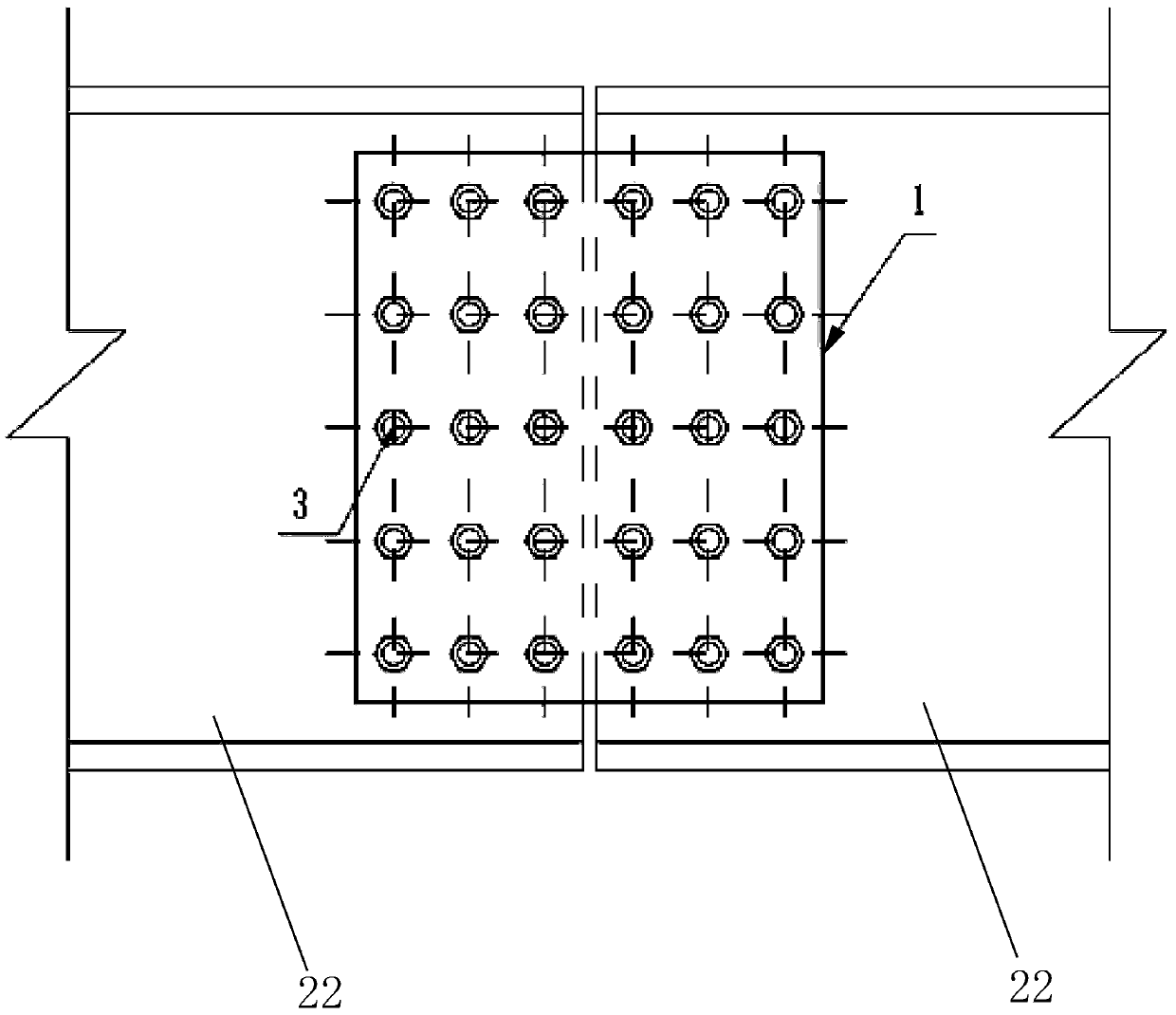

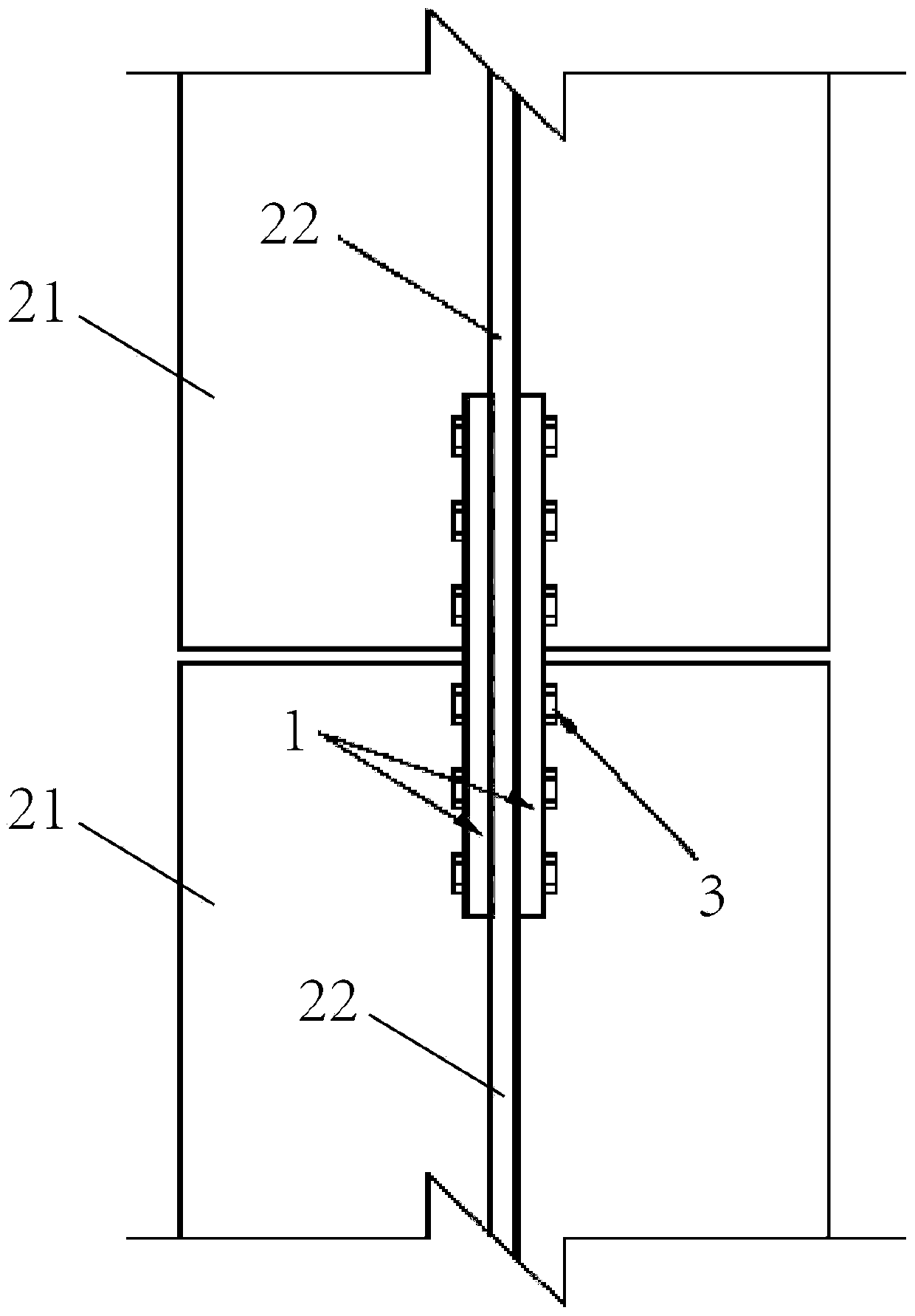

High-strength bolt friction-type connecting structure and connection node performance optimizing method thereof

InactiveCN104088370AIncrease coefficient of frictionIncreased shear capacityBuilding insulationsThermal sprayingEngineering

The invention relates to a high-strength bolt friction-type connecting structure and a connection node performance optimizing method thereof. The high-strength bolt friction-type connecting structure comprises a plurality of steel beams and connecting cover boards; an aluminium-sprayed layer is arranged on the outer surface of each connecting cover board; the connecting cover boards are respectively and fixedly arranged on a plurality of abutted steel beams by bolts; paint-sprayed layers are arranged at the joints of the steel beams; the connecting cover boards cover the paint-sprayed layers. The high-strength bolt friction-type connecting structure has the benefits that friction surfaces between the paint-sprayed layers increase friction coefficients and anti-sliding coefficients of the connecting cover boards and the steel beams to be connected so as to improve shear resistance of connection nodes; thermal spraying of aluminium has the effect of protecting a steel and iron matrix again, so that the connection nodes have strong integral corrosion resistance; aluninium is a metal with strong activity and is very easy to combine with oxygen to generate a compact and hard oxide protection layer, so that an aluminium coating is effectively prevented from being further oxidized, has a longer protection period, does not need to be repaired and maintained all the year round, and avoids waste of labor cost.

Owner:CHINA CONSTR STEEL STRUCTURE CORP LTD

Environment-friendly anti-rust oil composition for bearings

ActiveCN104450095AExcellent heat and humidity resistanceExcellent anti-salt spray anti-rust performanceLubricant compositionHigh carbonPetroleum

The invention discloses an environment-friendly anti-rust oil composition for bearings. The environment-friendly anti-rust oil composition comprises the following components in percentage by weight: 2%-8% of petroleum calcium sulfonate, 0.5%-8% of oxidized paraffin calcium soap, 0.5%-3% of oleoyl sarcosine tallow amine salt, 1%-4% of a film-forming agent and the balance of machine oil. The anti-rust oil composition disclosed by the invention has good wettability and blocking property, has excellent damp-heat resistance and salt fog protection resistance on bearings of high-carbon alloy steel, copper alloy or steel and copper assemblies, has good sweat corrosion resistance, does not contain a volatile hydrocarbon compound, or barium and other heavy metals, and is good in environmental protection capability and safe to use. According to the environment-friendly anti-rust oil composition for the bearings disclosed by the invention, a film layer is good in protective performance and long in protective cycle, and especially has excellent damp-heat resistance and salt fog protection resistance on high-carbon bearing steel materials and bearing steel / copper alloy bearing assemblies; the anti-rust oil film has good sweat corrosion resistance; and the oiled bearings have good anti-pollution and anticorrosion properties.

Owner:JIANGSU XINLU NEW MATERIALS CO LTD

Composite chromium-free corrosion inhibition passivator as well as preparation and application thereof

The invention provides a composite chromium-free corrosion inhibition passivator as well as preparation and application thereof. The passivator is composed of an agent A and an agent B in a mass ratioof 1 : 2.5-2.8, wherein the agent A comprises humic acid, barium metaborate, magnesium nitride, hydrogenated polydimethylsiloxane and styrene-acrylic emulsion; the agent B comprises phosphate, nanoscale mineral powder, plant slurry, bis (dicarbonyl cyclopentadiene iron), a silane coupling agent, waterborne silicon resin and deionized water. According to the composite chromium-free corrosion inhibition passivator as well as the preparation and application thereof, the self-made agent A and the self-made agent B are compounded, the synergistic effect of the components is remarkably improved through reasonable raw material selection and treatment, safety and high efficiency are achieved, the prepared passivator is stable in film layer and high in binding force, the passivator has good corrosion-resistant protection effects on chemical reagent, acid-base environment and various heavy metal pollutions, the overall wear resistance is obviously improved, the comprehensive quality is obviously improved, the protection period is effectively prolonged, and the passivator is worthy of popularization and application.

Owner:安徽禹锋数据科技有限公司

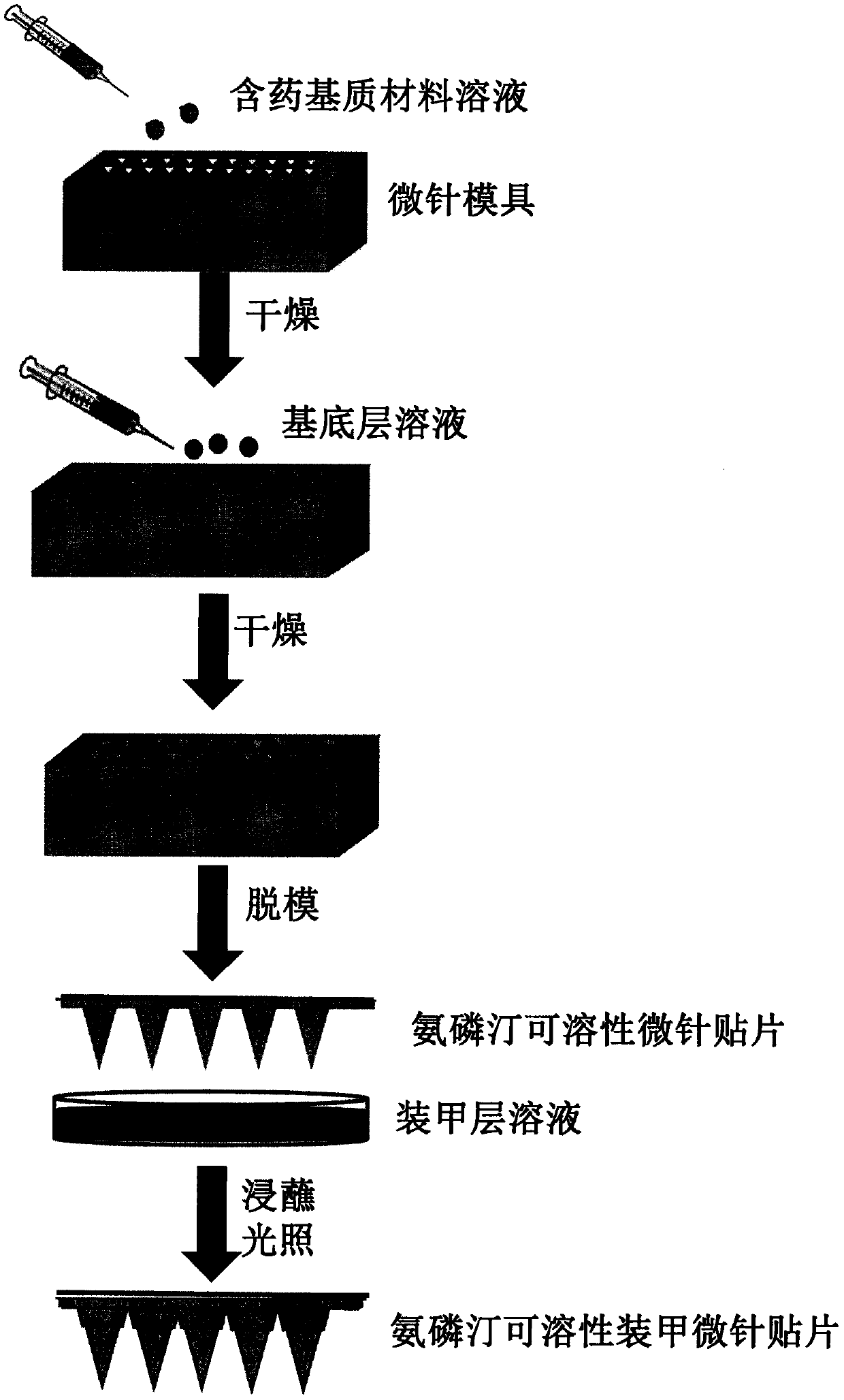

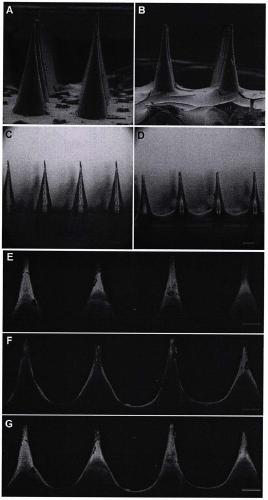

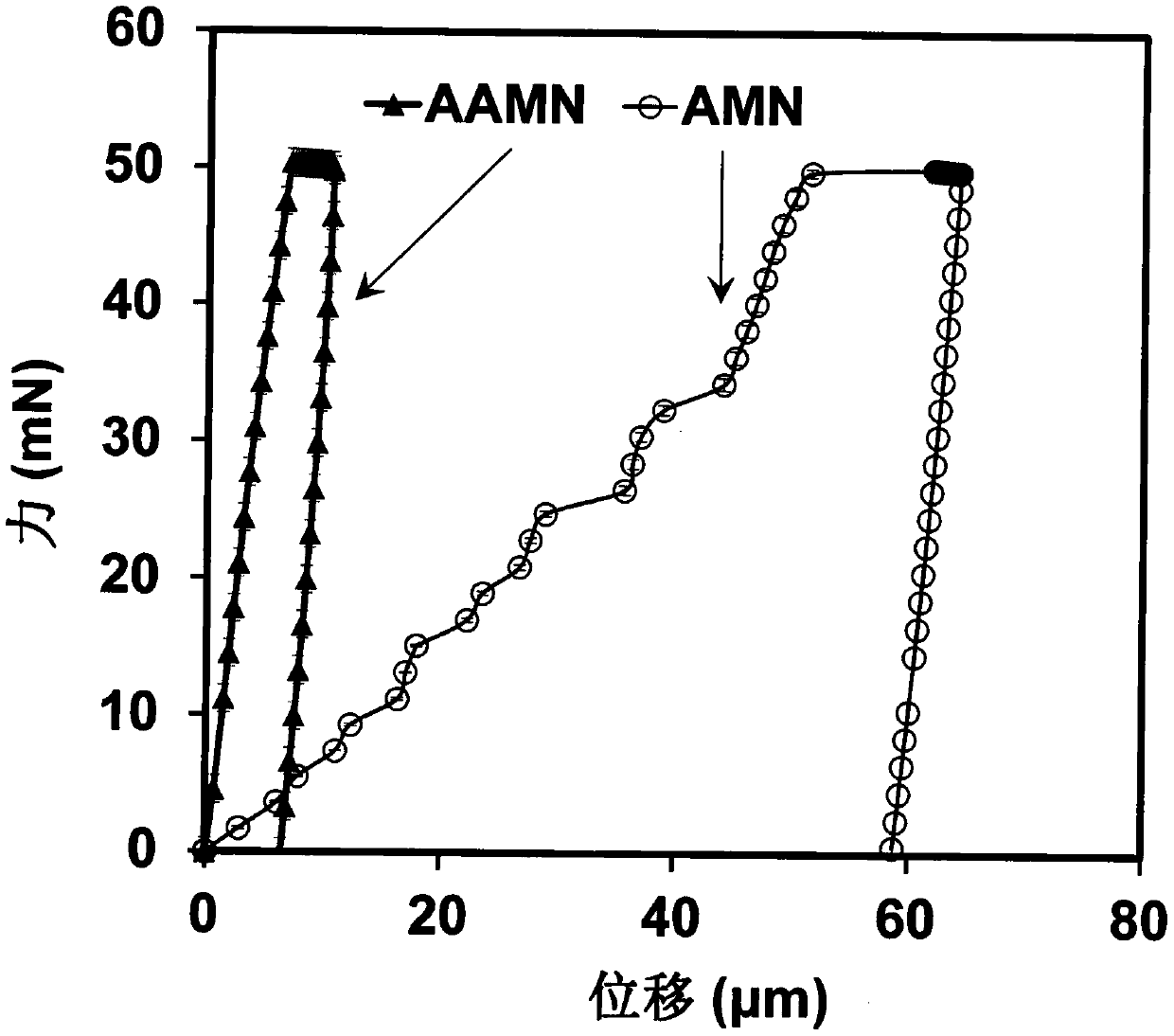

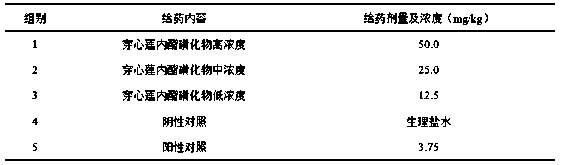

Amifostine soluble armored microneedle patch

InactiveCN111467300AAvoid breakingDifficult to penetrate the stratum corneumOrganic active ingredientsMicroneedlesPharmaceutical drugAmifostine

The invention discloses an amifostine soluble armored microneedle patch. The microneedle patch is composed of an amifostine soluble armored microneedle array and a substrate layer. The amifostine soluble armor microneedle structurally comprises a needle and an armor layer. The armored microneedle can greatly improve the drug dosage, does not influence the mechanical strength, can be smoothly inserted into the skin to implement transdermal drug delivery, achieves a long-time and high-efficiency cell protection effect, and can be used for radiation protection and chemotherapy protection.

Owner:ACADEMY OF MILITARY MEDICAL SCI

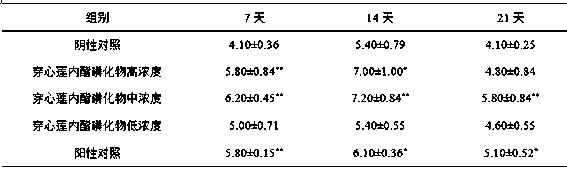

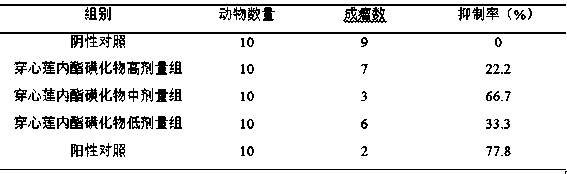

Andrographolide sulfonate and preparation method and application thereof

ActiveCN109942520AIncrease weightAvoid generatingOrganic active ingredientsOrganic chemistrySulfonateCarbonization

The invention discloses an andrographolide sulfonate and a preparation method and application thereof, and relates to the technical field of pharmacy. The method comprises the following steps of: dissolving andrographolide in a first solvent; dissolving sulfur trioxide in a second solvent, wherein the second solvent is a non-aqueous or non-protic solvent; adding the sulfur trioxide into the andrographolide to react to obtain a reaction solution, adjusting the pH of the reaction solution to be neutral, and removing the solvent to obtain a crude product; and dissolving the crude product in distilled water, filtering to obtain a filtrate, removing the solvent to obtain a solid, and drying to obtain the andrographolide. The method uses sulfur trioxide as a sulfonating agent of andrographolide,and has the advantages of high reaction activity and mild conditions. The reaction system is an anhydrous system, and can effectively avoid sulfur trioxide and water from generating concentrated sulfuric acid, thereby avoiding hydrolysis damage and dehydration carbonization of the product and ensuring the yield and quality of the product. The method has simple process and convenient operation, and is suitable for industrial production. The andrographolide sulfonate has the effects of prolonging antibody protection period, increasing body weight and resisting tumor.

Owner:大理金明动物药业有限公司

Sunscreen wax for protecting automobile paints

The invention discloses a sunscreen wax for protecting automobile paints. The sunscreen wax is produced from, by weight, 3-8 parts of homosalate, 2-6 parts of nanometer zinc oxide, 2-5 parts of eucalyptus oil, 2-6 parts of cocamidopropyl betaine, 2-8 parts of a pomegranate rind extract product, 1-5 parts of pearl powder, 2-5 parts of glycerin, 2-6 parts of palm wax, and the balance of distilled water. The automobile paint wax produced in the invention has super strong sunscreen and ultraviolet (UVB and UVA) prevention properties, can be adhered to the automobile paints in order to realize a long protection time, reduce the temperature outside automobiles, protect the automobile paints, prolong the service life of the automobile paints, restore fine scratches on the surfaces of the automobile paints, prevent slight scratches and keep the automobile paints bright like new, also has sterilizing and antibiosis effects, has no irritation to skins or eyes, is safe to use, and can be safely waxed by onsite construction personnel.

Owner:鄢海军

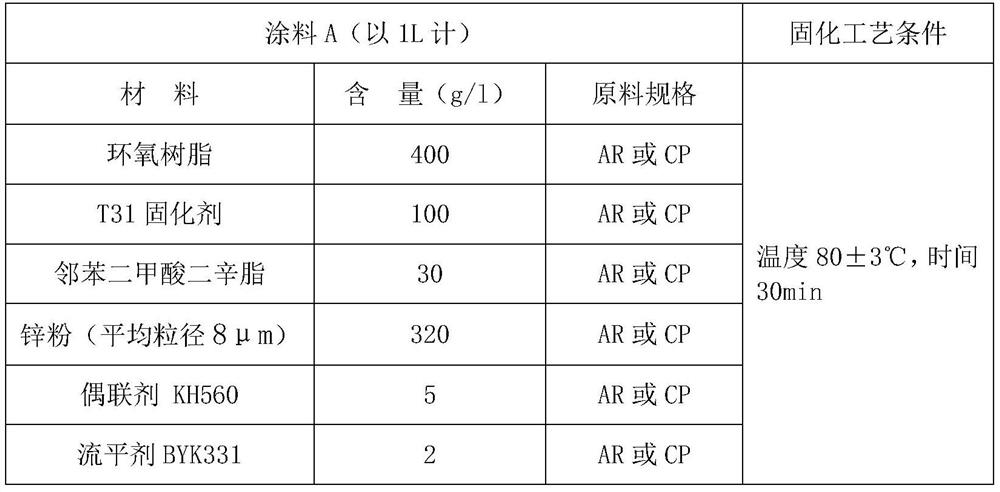

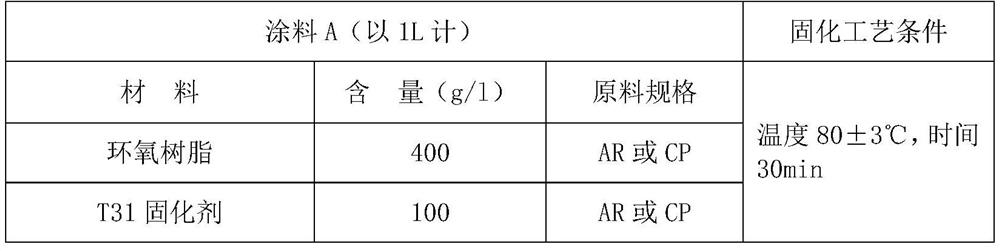

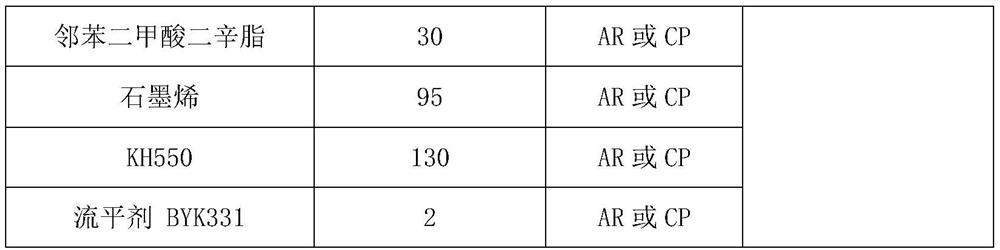

Metal surface protective coating layer and preparation method thereof

PendingCN112063268AImprove corrosion resistanceLong protection periodLiquid surface applicatorsAnti-corrosive paintsCorrosionCoating

The invention belongs to the technical field of metal protection, and particularly relates to a metal surface protective coating layer. The metal surface protective coating layer comprises coating layers A and coating layers B, and the coating layers A and the coating layers B respectively comprise anode particles and cathode particles and are alternately arranged. The metal surface protective coating layer is good in corrosion resistance, good in damp-heat resistance and good in adhesive force, can be used in cooperation with various kinds of finish paint, and meets the protective requirementof the severe tropical marine atmospheric environment.

Owner:NO 59 RES INST OF CHINA ORDNANCE IND

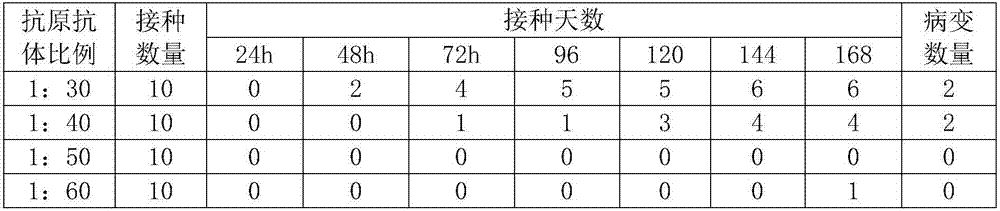

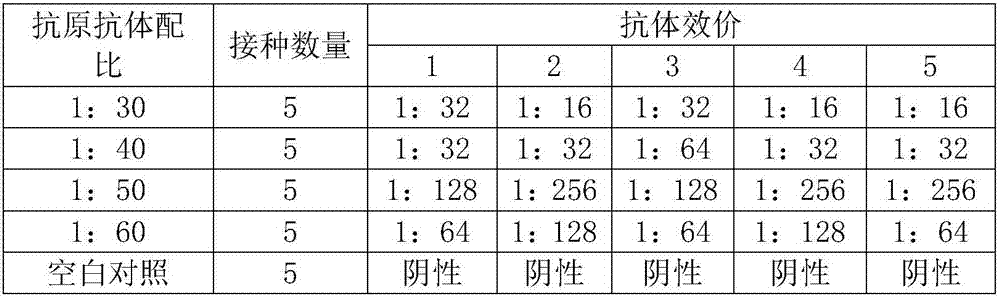

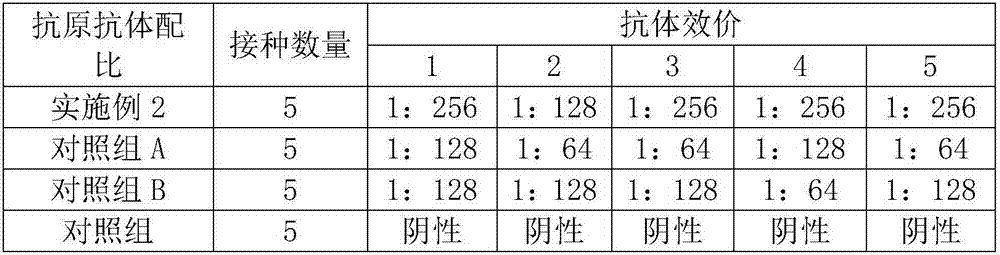

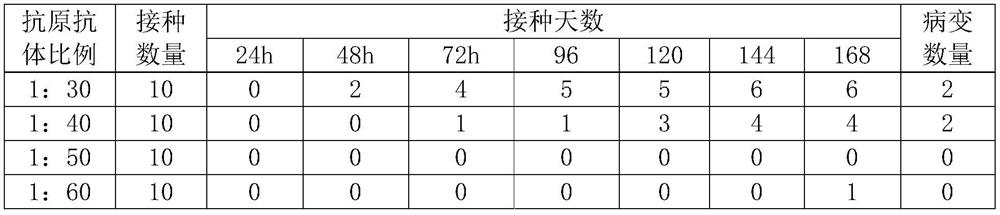

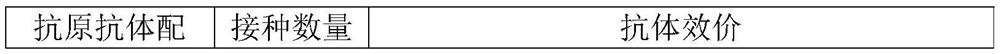

Duck hepatitis A virus antigen-antibody complex vaccine and preparation method thereof

ActiveCN107982532AHigh protection rateLong protection periodSsRNA viruses positive-senseViral antigen ingredientsDuck hepatitis A virusPropolis

The invention discloses a duck hepatitis A virus antigen-antibody complex vaccine and a preparation method thereof. The vaccine is an antigen-antibody complex obtained after a 3 type duck hepatitis Avirus antigen and a duck egg yolk antibody are mixed and react in a volume ratio of 1:50. Compared with the prior art, the vaccine disclosed by the invention has the advantages that magnesium sulfate,sodium chloride and propolis are added into the 3 type duck hepatitis A virus antigen, and the antigen is used for immunizing laying ducks to prepare duck egg yolk antigens, and finally egg yolk antibodies and the 3 type duck hepatitis A virus antigen are reasonably matched, so that the 3 type duck hepatitis A virus antigen-antibody complex vaccine is prepared. Multiple tests show that binding efficiency of the obtained antigen-antibody complex takes effect after the vaccine is injected within 2 hours, no blank immunization period exists, titer is high, safety is good, protection rate is high, and protection period is long.

Owner:ANHUI QIANGYING DUCK IND GRP +1

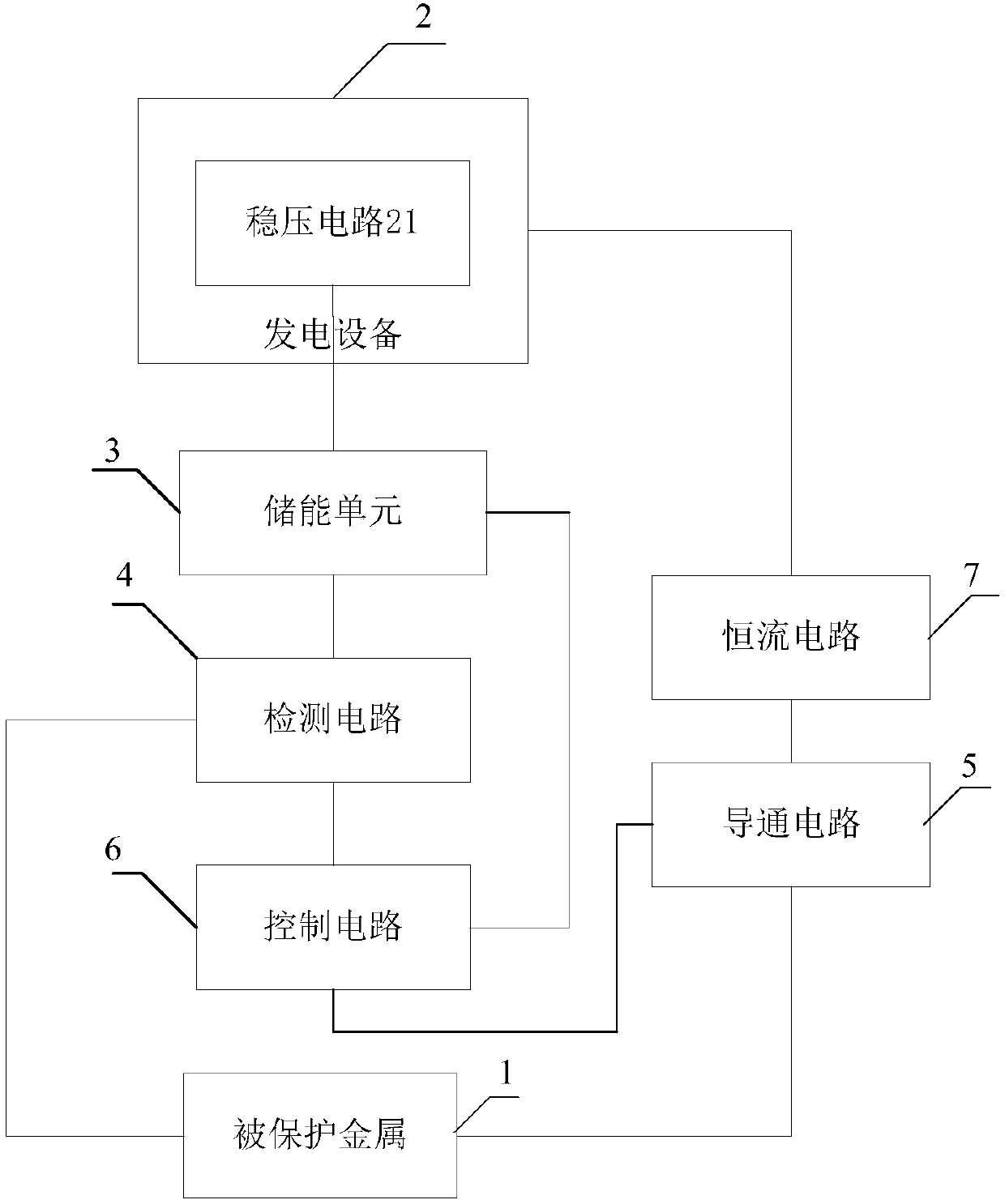

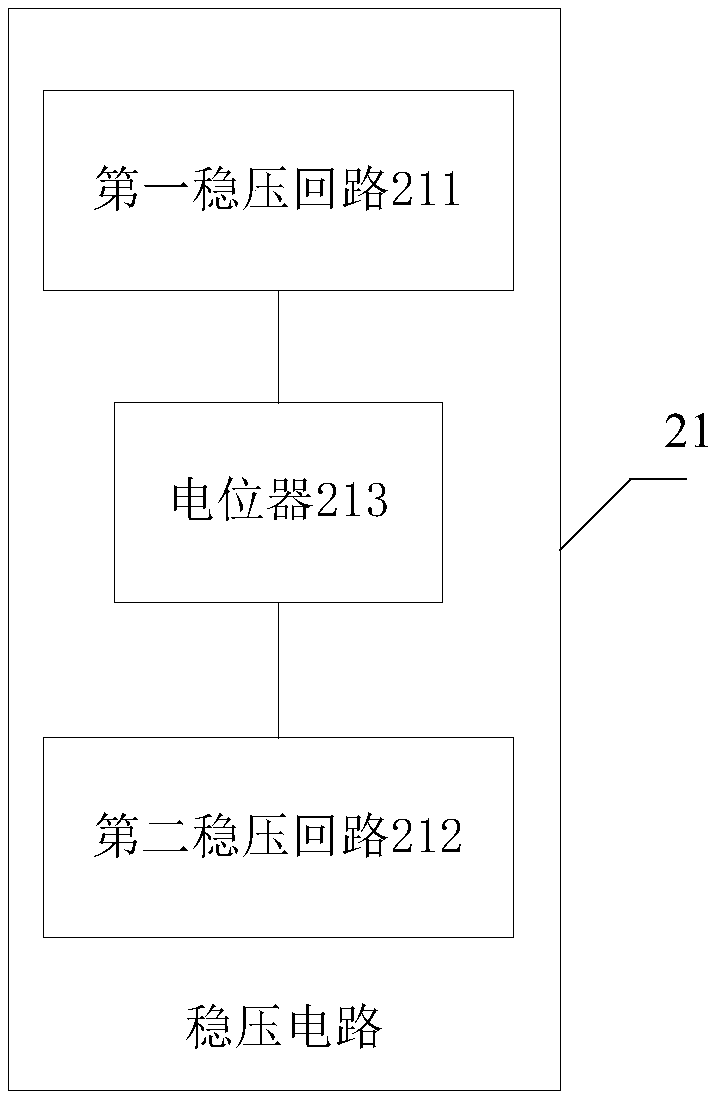

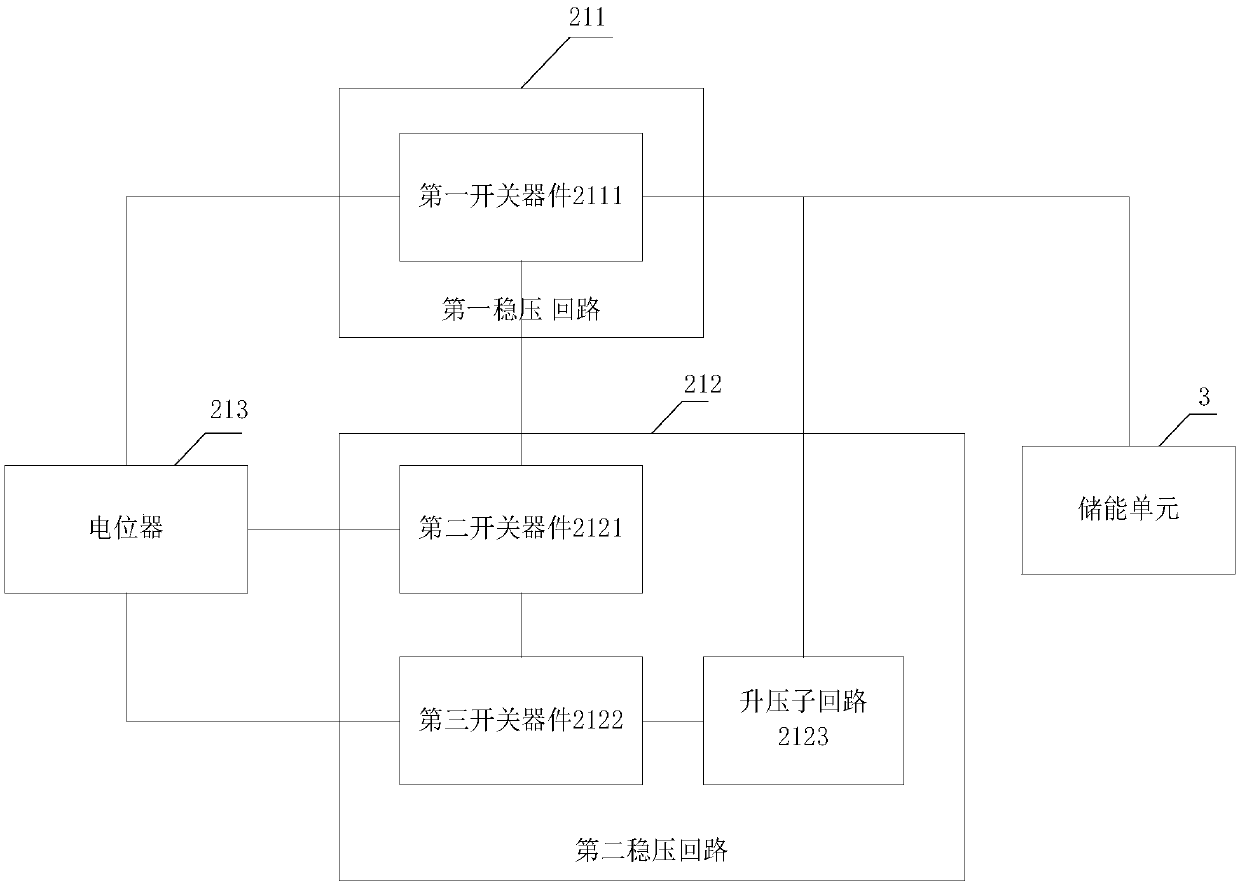

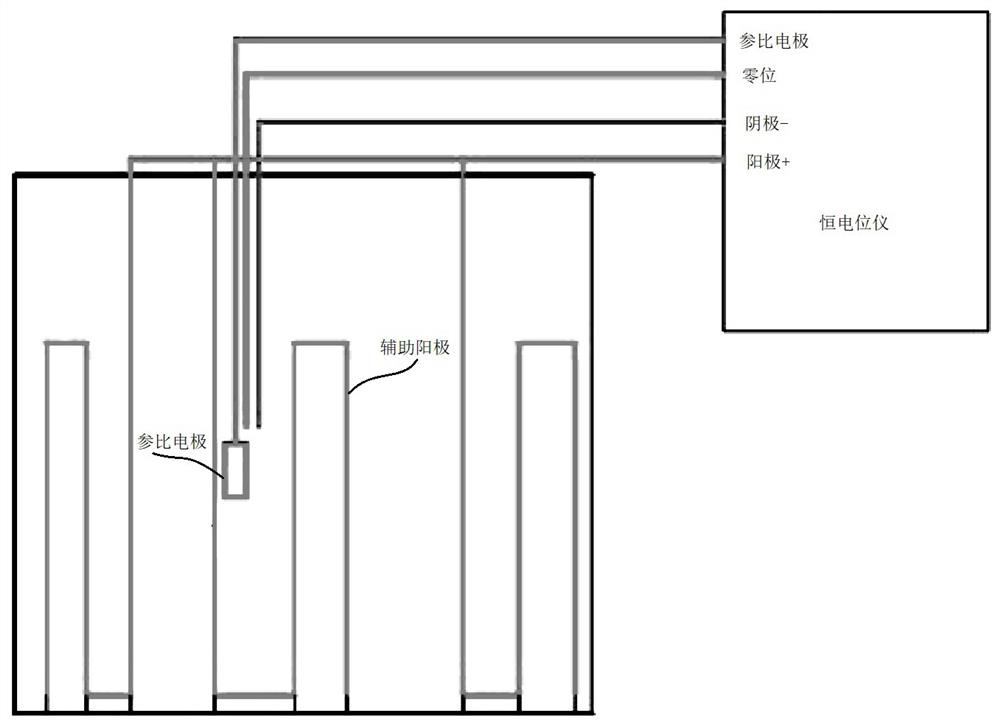

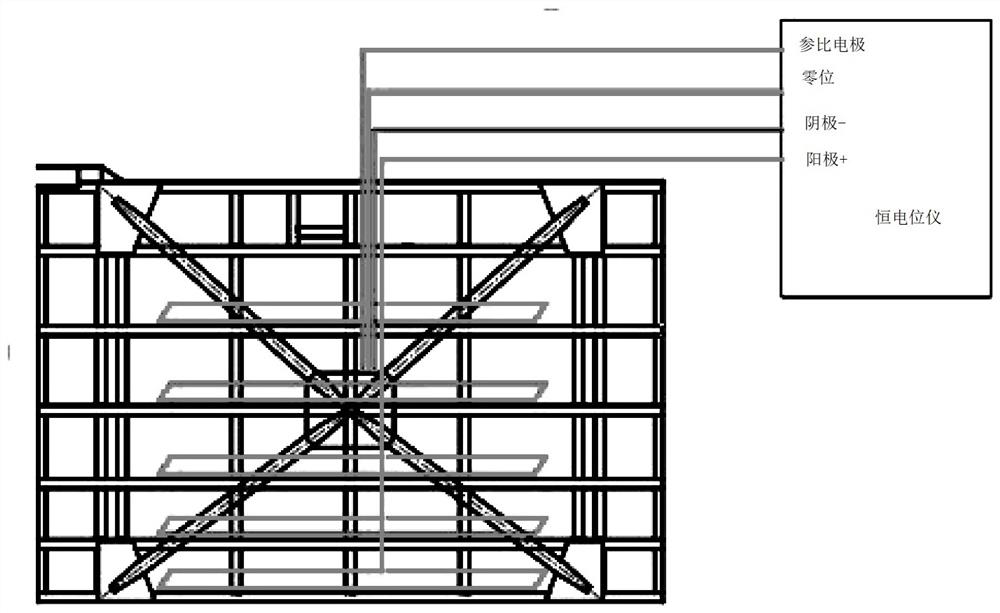

Protection system for preventing electrochemical corrosion of metal and control method for preventing electrochemical corrosion of metal

The invention discloses a protection system for preventing electrochemical corrosion of metal and a control method for preventing electrochemical corrosion of the metal. The protection system for preventing electrochemical corrosion of the metal comprises the protected metal arranged on the ground or underground, and further comprises power generation equipment for generating electric energy, an energy storage unit connected with the power generation equipment and used for storing and providing electric energy, a detection circuit which receives the detection voltage of the protected metal, compares the detection voltage with preset protection voltage, and outputs a control signal, a conducting circuit and a control circuit which receives the control signal and controls the on-off of the conducting circuit according to the control signal, wherein the power generation equipment is connected with the protected metal through the conducting circuit. According to the protection system for preventing the electrochemical corrosion of the metal and the control method for preventing the electrochemical corrosion of the metal, the power generation equipment arranged on the ground can provideworking current for the control circuit, enables the output current of the power generation equipment to flow into the protected metal according to preset conditions through the control circuit, so that electrochemical corrosion of the protected metal is effectively prevented, and a longer protection period is achieved.

Owner:北京太古行科技发展有限责任公司

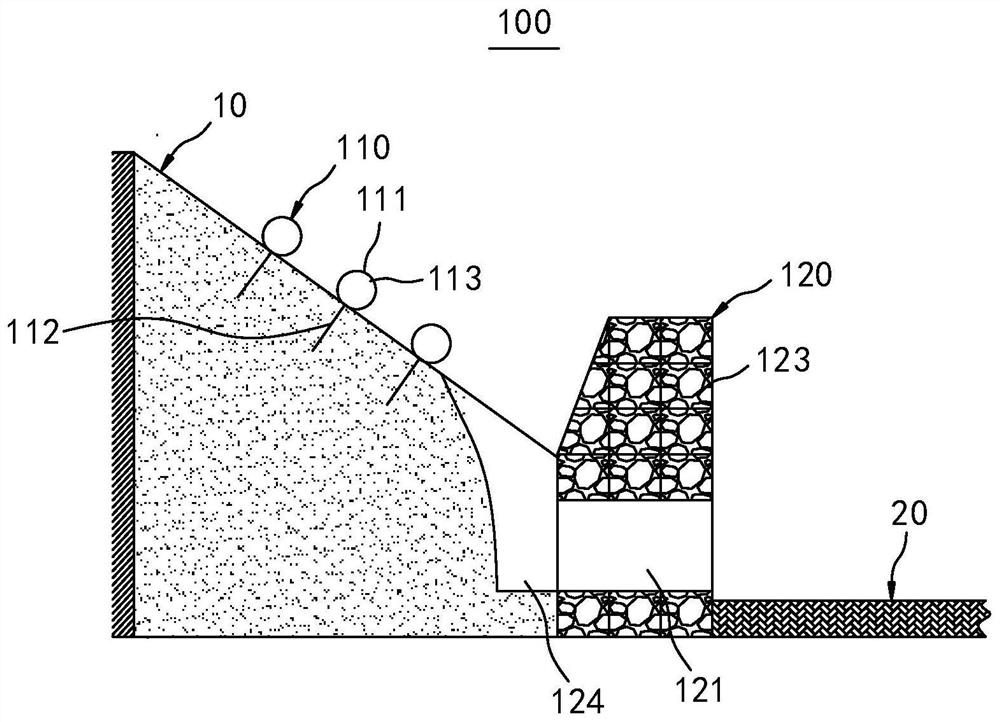

Side slope protection structure

The invention relates to the technical field of slope protection, in particular to a side slope protection structure. The side slope protection structure comprises a buffering assembly and a steel bar gravel cage retaining wall. The buffering assembly comprises a buffering piece and a first anchoring piece. The buffering piece extends along the length direction of the slope; the first anchoring part is connected with the buffering piece and is anchored on the slope surface of the side slope; the steel bar gravel cage retaining wall extends in the length direction of the side slope and is located between the slope toe of the side slope and the road, and the top of the steel bar gravel cage retaining wall is higher than the slope toe. According to the slope protection structure, the protection effect of the slope can be improved, the slope protection cost is reduced, and the protection period can be prolonged; and the self-drainage effect is good, and the situation that water is accumulated at the slope toe can be avoided.

Owner:成都未来智隧科技有限公司

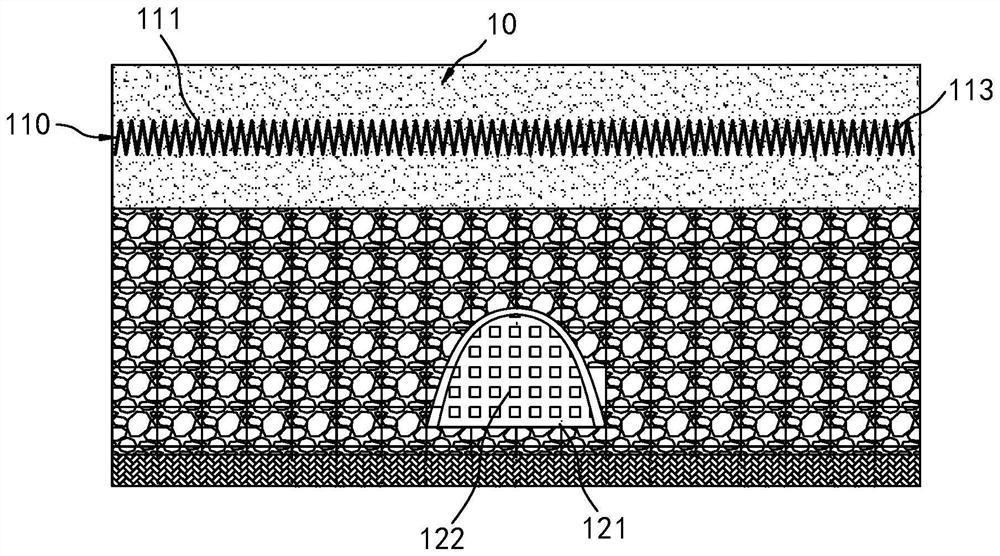

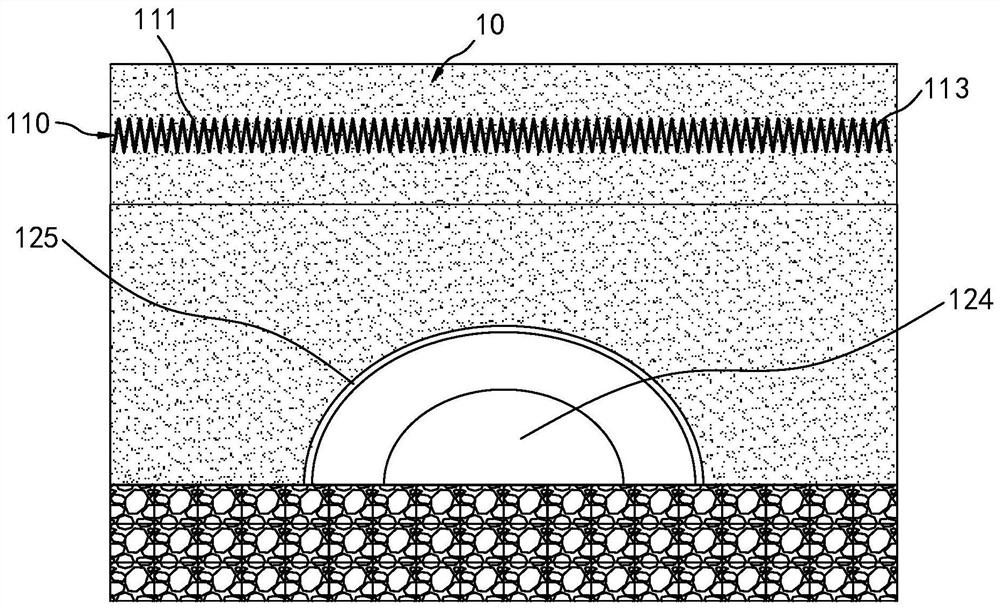

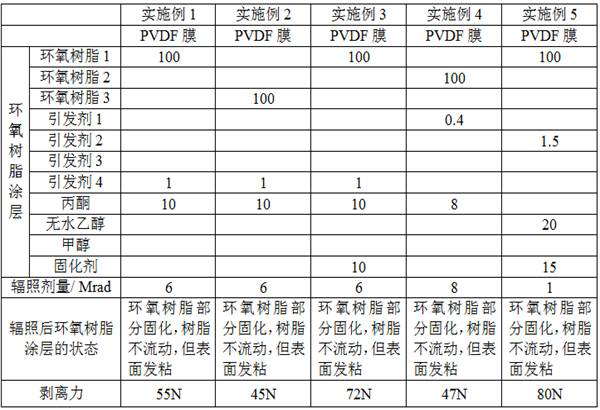

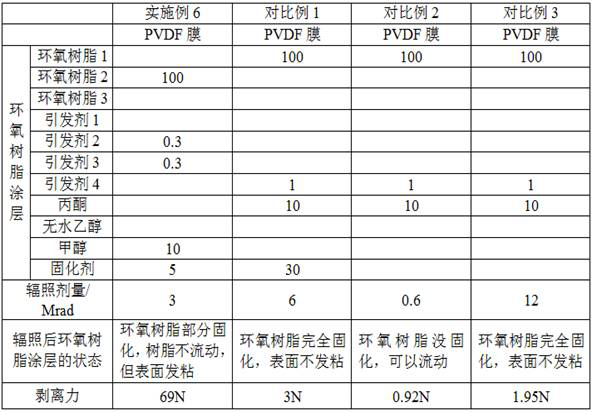

Wind turbine blade leading edge protection material and preparation method and application thereof

ActiveCN112592503AImprove the protective effectLong protection periodMachines/enginesWind energy generationEpoxyMarine engineering

The invention discloses a wind turbine blade leading edge protection material and a preparation method and an application thereof, and the wind turbine blade leading edge protection material comprisesa PVDF film and an epoxy resin-based coating; wherein the epoxy resin-based coating comprises the following components in parts by weight: 100 parts of epoxy resin; 0.4-1.5 parts of an initiator; and8-20 parts of a solvent. According to the protection material, the polar epoxy resin coating is formed on the surface of the PVDF film by adopting an irradiation grafting method, so that the bondingperformance of the PVDF film is improved, the PVDF film and the blade can be integrally formed and cured when the wind turbine blade is poured and formed, and the PVDF film is firmly bonded with the surface of the wind turbine blade; the protection effect on the front edge of the wind turbine blade is good, the protection period is long, and the requirements that the wind turbine blade front edgeprotection material can achieve effective protection and is free of maintenance in the blade service period are met.

Owner:FSPG HI TECH

Preparation method of solid corrosion-inhibition scale-inhibition bar used for oil field

ActiveCN101781767BWell mixedThe method steps are simpleDrilling compositionPolyethylene glycolTricarboxylic acid

The invention discloses a preparation method of a solid corrosion-inhibition scale-inhibition bar used for an oil field, which relates to a production method of a chemical medicament used for the oil field. The preparation method comprises the following steps of: (1) mixing 30 to 40 percent of 2-phosphonobutane-1,2,4-tricarboxylic acid, 10 to 15 percent of polyethylene glycol, 10 to 15 percent ofsodium hexametaphosphate, 15 to 25 percent of Span-60 and 20 to 30 percent of stearic acid evenly, wherein the percent is the mass percent of the sum of each component occupying all the components; and (2) putting all the evenly mixed components into a bar type mold, pressing into a bar type by using a press machine and forming a finished product, wherein the pressure applied by the press machineis 15 to 20 tons. The method has the advantages of simple preparation process, even mixing of the components, trouble saving and labor saving, so that the method is suitable for mass and industrialized production and large-scale popularization and application.

Owner:BC P INC CHINA NAT PETROLEUM CORP +1

Anti-corrosion treatment process for ship lock inverted-V-shaped door metal structure

InactiveCN113814145AReduce the impactSolve pollutionPretreated surfacesCoatingsMechanical engineeringElectrical current

The invention provides an anti-corrosion treatment process for a ship lock inverted-V-shaped door metal structure. The anti-corrosion treatment process comprises the following steps that S1, surface pretreatment is conducted on the inverted-V-shaped door metal structure, and attachments, rust and other impurities are removed; S2, coating corrosion prevention is conducted, specifically, a moisture-curing coating is sprayed on the inverted-V-shaped door metal structure, and the spraying thickness is 0.4-1mm; and S3, a direct-current power source and an auxiliary anode are additionally arranged, the auxiliary anode is connected with the positive electrode of the direct-current power source to serve as an anode, the ship lock inverted-V-shaped door metal structure is connected with the negative electrode of the direct-current power source to serve as a cathode, protective current is provided by the direct-current power source, and an impressed current cathodic protection system is formed. Through the operation, anti-corrosion treatment of the ship lock inverted-V-shaped door metal structure is completed. According to the anti-corrosion treatment process, the comprehensive anti-corrosion technology combining the coating and impressed current cathodic protection is adopted, effective corrosion prevention of the large ship lock inverted-V-shaped door metal structure can be achieved, and the service life of the inverted-V-shaped door metal structure is prolonged.

Owner:THREE GORNAVIGATION AUTHORITY

Steep slope protection method based on reinforced water and soil protection blanket

The invention discloses a steep slope protection method based on a reinforced water and soil protection blanket. The reinforced water and soil protection blanket is laid on a slope and a mode of spray-seeding a fiber base material (containing seeds) is combined, vegetation, a blanket body, soil and the like are integrated. According to the steep slope protection method based on the reinforced water and soil protection blanket, the safety performance is high, the water and soil protection effect is good, and the landscape ecology is harmonious and natural. Construction is simple, the efficiency is high, the manufacturing cost is low, the protection period is long, and the annual repair cost is avoided.

Owner:厦门仁祥生态科技有限公司

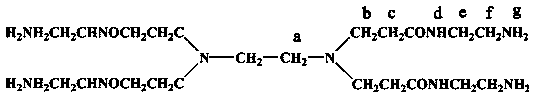

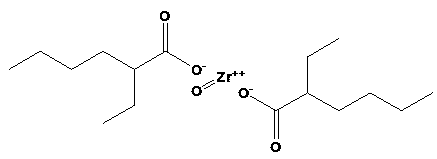

Salt spray anti-rust oil containing organic amine-carboxylate compound and its preparation method and application

ActiveCN106701254BHigh resistance to salt sprayExcellent heat and humidity resistanceAdditivesCarboxylic acidSolvent

The invention provides salt-spray-resistant anti-rusting oil containing an organic amine-carboxylate compound, as well as a preparation method and application of the anti-rusting oil. The anti-rusting oil provided by the invention has the advantages of being high in salt spray resistance and damp heat resistance, being friendly to the environment and preventing pollution. 15# machine oil and solvent oil are taken as a solvent, and the prepared organic amine-carboxylate compound and three other common anti-rusting agents in the market are added, so that the anti-rusting oil has a long rust-proof life on metal products, particularly has a long protection period on easily corrosive powder metallurgy ferrous metals. The anti-rusting oil disclosed by the invention is clear and transparent in appearance, does not have any precipitate, has high adhesive force on the metal surface and does not influence the appearance of the metal products. Moreover, the preparation method disclosed by the invention is simple, easy to operate, low in cost and suitable for large-scale production.

Owner:NANJING FORESTRY UNIV

A kind of duck hepatitis A virus antigen-antibody complex vaccine and preparation method thereof

ActiveCN107982532BHigh protection rateLong protection periodSsRNA viruses positive-senseViral antigen ingredientsDuck hepatitis A virusAntigen

The invention discloses a duck hepatitis A virus antigen-antibody complex vaccine and a preparation method thereof. The vaccine is an antigen-antibody complex obtained by mixing and reacting type 3 duck hepatitis A virus antigen and duck yolk antibody at a volume ratio of 1:50. Compared with the prior art, the present invention prepares the duck yolk antigen by adding magnesium sulfate, sodium chloride and propolis to the type 3 duck hepatitis A virus antigen, and immunizes laying ducks with the antigen, and finally carries out the yolk antigen through the egg yolk antibody and the type 3 duck hepatitis A virus antigen. Reasonable proportioning, made type 3 duck hepatitis A virus antigen-antibody complex vaccine, after many tests showed that the combination efficiency of the antigen-antibody complex prepared by this method took effect within 2 hours after the vaccine was injected, there was no immune blank period, and the vaccine was effective. High price, good security, high protection rate and long protection period.

Owner:ANHUI QIANGYING DUCK IND GRP +1

Universal metallic surface silanization treating agent, preparation and use thereof

InactiveCN101476118BHigh practical application valueImprove and enhance practical application valueMetallic material coating processesOrganic solventSilanization

The invention discloses a versatile metal surface silanization treating agent, a preparing method and an application thereof. The preparing method includes steps as follows: mixing an organic solvent with 5-20 volumes and an silane coupling agent with 5-20 volumes evenly for obtaining the silane main solution, injecting a pre-adjust PH value deionized water with 100 volumes into the silane main solution for obtaining composite mixing solution; controlling temperature of the composite mixing solution in 20-60 DEG C and hydrolysis during 0.5-12 hours; cooling to a room temperature, water phase is the metal surface silanization treating agent after the solution is layered; the organic phase can supply the silane coupling agent and uses repeatedly. The treating agent, the method and the application provided by the invention have advantages of lower cost, safe in utilization, simple manufacturing equipment, convenient for use and wide metal processing range, such as steel, galvanized steel, copper, zinc, aluminium, aluminium alloy and magnesium alloy. The method has better processing effect, strong ability of hydrolytic resistance, washing resistance and salt mist resistance, longer protective period for metal, and increases and enhances fact application value of the silanization treating technique, helps the development of the metal surface silanization treating technique industrialization.

Owner:HUNAN UNIV

Solid corrosion and scale inhibitor for oil field

InactiveCN101805597BLow cost of corrosion and scale inhibitionReduce filling operationsDrilling compositionBorehole/well accessoriesSODIUM METAPHOSPHATESodium phosphates

The invention discloses a solid corrosion and scale inhibitor for an oil field, which relates to the technical field of chemical medicine reagents used for the oil field. The solid corrosion and scale inhibitor comprises the following ingredients: 2-phosphonic acid butane 1, 2, 4-tricarboxylic acid PBTCA, polyethyleneglycol, sodium hexametahposphate, span-60 and stearic acid, wherein each ingredient accounts for the mass percent of the sum of all the ingredients as follow: 30 percent to 40 percent of 2-phosphonic acid butane 1, 2, 4-tricarboxylic acid PBTCA, 10 percent to 15 percent of polyethyleneglycol, 10 percent to 15 percent of sodium hexametahposphate, 15 to 25 percent of span-60 and 20 percent to 30 percent of stearic acid. The invention is particularly suitable for well tubes of oil-gas wells with server corrosion and scale conditions, and has good corrosion and scale inhibition effects on underground pipe posts and equipment.

Owner:CHINA NAT PETROLEUM CORP CHUANQING DRILLING ENG CO LTD

A kind of environment-friendly slow-release polymer scale inhibitor and preparation method thereof

ActiveCN107304078BBiodegradableWon't happenWaste water treatment from quariesWater treatment compoundsOil fieldEnvironmental engineering

The invention discloses an environment-friendly slow-release polymer scale inhibitor, which is good in scale inhibition and slow release effects. The dosage of the scale inhibitor which needs to be added within a maintenance cycle can be estimated in advance according to the actual production condition of an oil well; the scale inhibitor is put into a sieve tube at the lower end of an oil-well pump of the oil well in regular repair and maintenance processes of an oil-well pipeline and a gathering pipeline; scale inhibition components are slowly dissolved and released to achieve the long-term scale inhibition effect through one-off addition when a produced liquid flows through the sieve tube, so that the long-term effective concentration can be maintained, the scale inhibiting ratio within the effective service cycle (about 90-120d) is greater than 85%, the effective release time can reach 90d or over, the protection period on the pipeline is long, and the production and maintenance cost of an oil field can be effectively reduced. The environment-friendly slow-release polymer scale inhibitor is nontoxic, harmless and degradable, and does not harm the formation and surrounding environment, and is environmentally friendly and suitable for popularization and application.

Owner:WUHAN UNIV OF TECH

Front edge protection wind power blade and forming method thereof

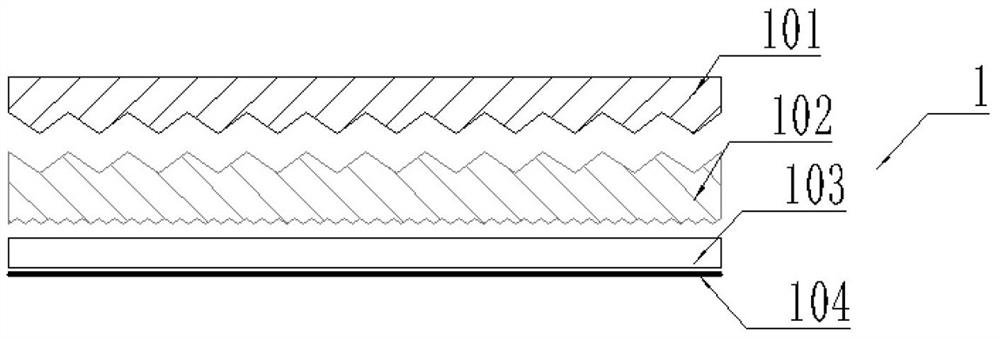

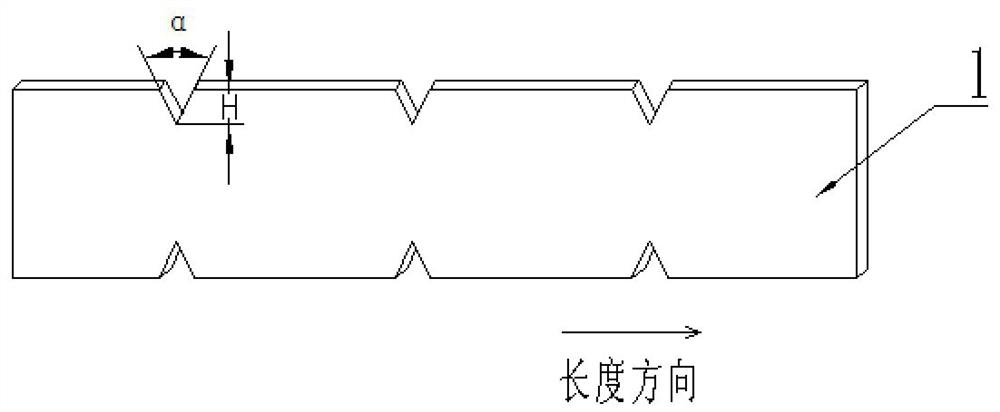

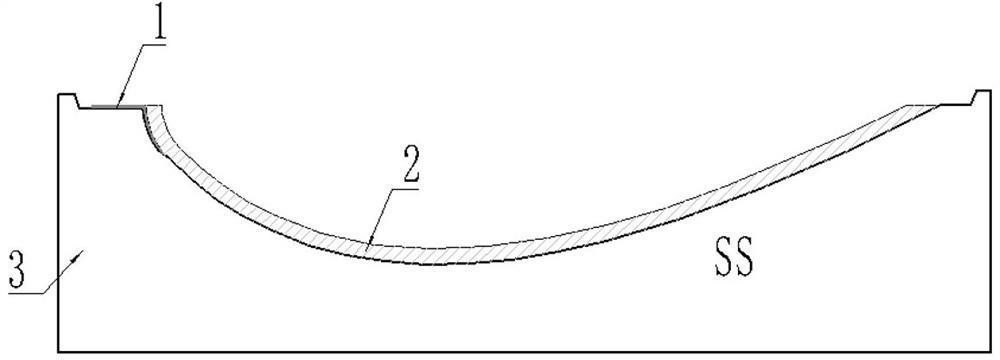

PendingCN114589938ASimple structureImprove hydrophobicityMachines/enginesWind energy generationGlass fiberPolymer modified

The invention discloses a front edge protection wind power blade and a forming method thereof, a front edge protection film is arranged on the front edge of the blade, and the front edge protection film is of a multi-layer structure and sequentially comprises a protection layer, a buffer layer and a bonding layer from outside to inside. The protective layer is made of polytetrafluoroethylene filled with a graphite reinforcing agent or a polymer modified material with the same performance, the buffer layer is made of high-elasticity polyurethane foam or high-density elastic foam with the same performance, and the bonding layer is a glass fiber adhesive tape. A V-shaped groove is formed in the front edge protective film, and the front edge protective film and the hyperboloid blade shell are good in shape follow-up performance during bonding. The front edge protective film can be integrally formed with a blade shell in a pouring mode, can also be installed after the blade is demolded, is simple in forming process, high in operability and long in service life, has conductivity and can conduct lightning stroke protection on the front edge of the blade.

Owner:厦门双瑞风电科技有限公司

A kind of environment-friendly bearing antirust oil composition

ActiveCN104450095BExcellent heat and humidity resistanceGood human sweat anti-rust performanceLubricant compositionPetroleumSOAP

The invention discloses an environment-friendly anti-rust oil composition for bearings. The environment-friendly anti-rust oil composition comprises the following components in percentage by weight: 2%-8% of petroleum calcium sulfonate, 0.5%-8% of oxidized paraffin calcium soap, 0.5%-3% of oleoyl sarcosine tallow amine salt, 1%-4% of a film-forming agent and the balance of machine oil. The anti-rust oil composition disclosed by the invention has good wettability and blocking property, has excellent damp-heat resistance and salt fog protection resistance on bearings of high-carbon alloy steel, copper alloy or steel and copper assemblies, has good sweat corrosion resistance, does not contain a volatile hydrocarbon compound, or barium and other heavy metals, and is good in environmental protection capability and safe to use. According to the environment-friendly anti-rust oil composition for the bearings disclosed by the invention, a film layer is good in protective performance and long in protective cycle, and especially has excellent damp-heat resistance and salt fog protection resistance on high-carbon bearing steel materials and bearing steel / copper alloy bearing assemblies; the anti-rust oil film has good sweat corrosion resistance; and the oiled bearings have good anti-pollution and anticorrosion properties.

Owner:JIANGSU XINLU NEW MATERIALS CO LTD

A surface-modified nickel-based sulfur-resistant hydrogenation catalyst and its preparation method

ActiveCN106492859BGuaranteed quantityHigh activityPhysical/chemical process catalystsHydrocarbon oils treatmentHydrogenSulfur

The invention discloses a surface modified nickel based sulfur resistant hydrogenation catalyst and a preparation method thereof, and belongs to the technical field of nickel-based catalysts. The catalyst is characterized by comprising an inorganic oxide carrier with a surface and holes in preset sizes, and a complex shielding layer suitable for the interaction with the surface, with the size being in interaction with the carrier and active metal. By applying the shielding layer onto the surfaces and the holes of the carrier and active components, the shielding layer complex is converted into metal, metal oxide and a mixture of the metal and the metal oxide through calcinations, and the catalyst is prepared through hydrogen reduction. The catalyst greatly improves the activity in shielding metal components contained in the catalyst, reduces the content of shielding metal, and guarantees the quantity of active centers in catalyst metal.

Owner:新疆佳宇恒能源科技有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com