Metal surface protective coating layer and preparation method thereof

A metal surface, protective coating technology, applied in the direction of coating, device for coating liquid on the surface, anti-corrosion coating, etc., can solve the problems of poor reliability, poor corrosion resistance, short protection period, etc., to achieve protection Long cycle, good corrosion resistance and good adhesion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0038] For the preparation of protective coatings for steel materials, the sample material is 45 steel, the size is 150mm×100mm×3mm, the surface is milled to a roughness of ≤1.6, and it is ready for use.

[0039] ①. Soak the steel piece in acetone or solvent gasoline for 2 minutes, then wipe it clean with absorbent cotton, and then degrease it in an alkaline degreasing solution at 80°C for 30 minutes; then rinse it with tap water for 45 seconds.

[0040] ②. Preparation of phosphating film: Put the surface-conditioned sample into the zinc-based phosphating solution at 58°C, keep it for 5 minutes, take it out, rinse it with tap water for 45s, and dry it.

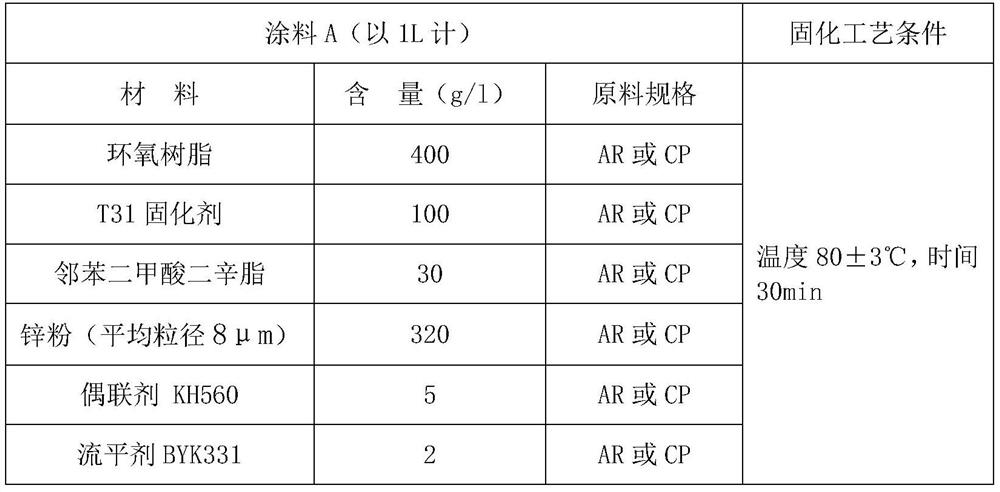

[0041] 3. Preparation of coating A: Coating A was prepared on the sample phosphating film surface by air spraying method, wherein the coating formula used for coating A is as shown in Table 1;

[0042] Before spraying, adjust the viscosity of the paint to 20s (measured by Tu-4# cup at room temperature). 15 μm, put the sample ...

Embodiment 2

[0053] For the preparation of high corrosion-resistant protective coatings for steel materials, the sample material is 45 steel, the size is 150mm×100mm×3mm, the surface is milled to a roughness of ≤1.6, and it is ready for use.

[0054] ①. Soak the steel parts in acetone or solvent gasoline for 2 minutes, then wipe them clean with absorbent cotton, and degrease them in an alkaline degreasing solution at 80°C for 30 minutes; then rinse them with tap water for 40 seconds.

[0055] ②. Preparation of phosphating film: Put the surface-conditioned sample into the zinc-based phosphating solution at 55°C, keep it for 6 minutes, take it out, rinse it with tap water for 40s, and dry it.

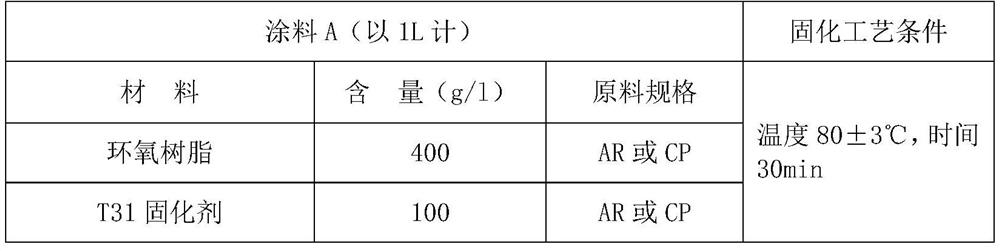

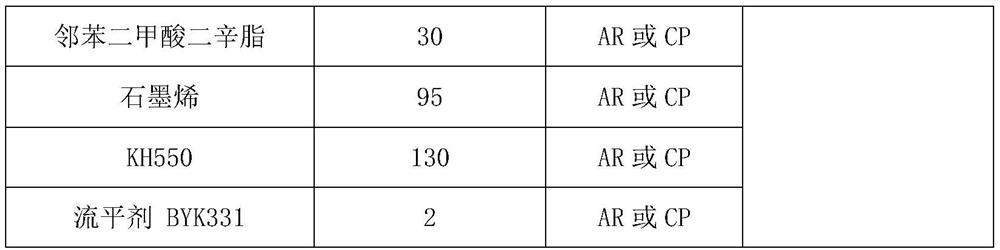

[0056] 3. Preparation of coating A: Coating A was prepared on the surface of the sample phosphating film by air spraying method, wherein the coating formula used for coating A is as shown in Table 3;

[0057] Before spraying, adjust the viscosity of the paint to 25s (measured by Tu-4# cup at room temp...

Embodiment 3

[0067] Preparation of high corrosion-resistant protective coating for aluminum alloy materials, the sample material is 7A04, the size is 150mm×100mm×3mm, the surface is milled to a roughness of ≤1.6, and it is ready for use.

[0068] ①. Soak the aluminum parts in acetone or solvent gasoline for 2 minutes, then wipe it with absorbent cotton, and then degrease it in an alkaline degreasing solution at 80°C for 30 minutes; then rinse it with tap water for 50 seconds.

[0069] ②. Preparation of anodized film: Soak in alkaline solution at 50°C for 60s. The main components of alkaline solution are: sodium hydroxide 50g / L, sodium gluconate 2g / L; rinse with tap water for 30s; Soak in dilute nitric acid for 5 minutes; rinse with tap water for 30 seconds; prepare aluminum alloy anodized film according to the solution formula and process conditions given in Table 4 for 15 minutes, then rinse with tap water for 60 seconds; seal the oxide film in boiling deionized water Processing time 15mi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com