Anti-corrosion treatment process for ship lock inverted-V-shaped door metal structure

A metal structure and anti-corrosion treatment technology, applied in the direction of pre-treatment surface, coating, special surface, etc., can solve the problems of reducing the safety and life of use, the metal structure is easy to be corroded, and endangering the safety of the ship lock operation, etc., so as to inhibit surface corrosion , excellent anti-corrosion performance, and low environmental impact

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

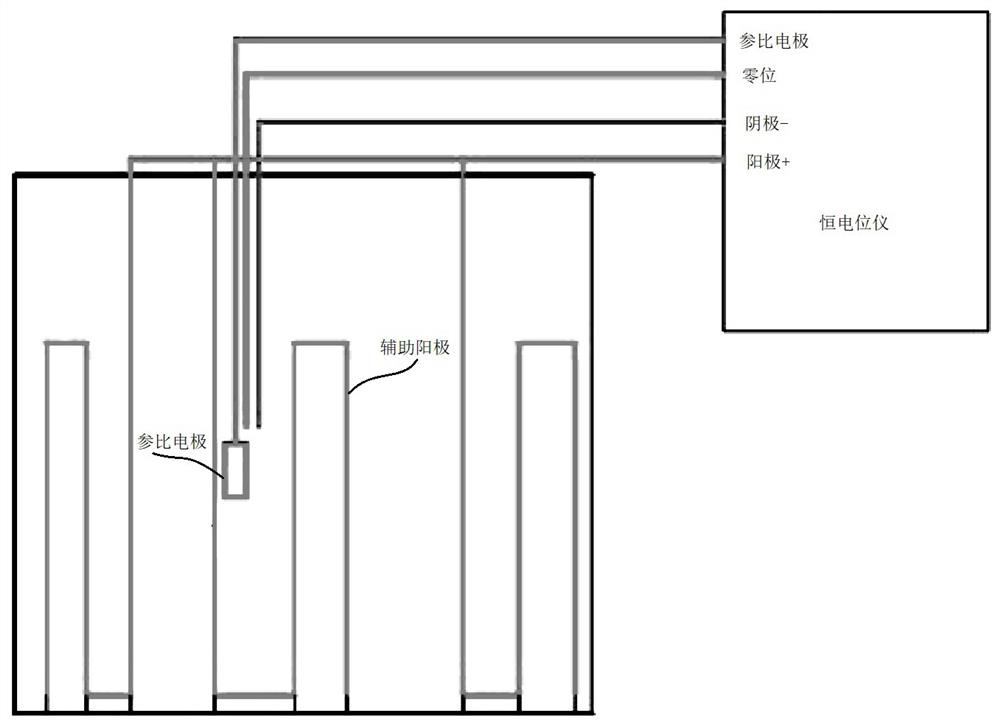

[0031] The coupon test is carried out by using the combined scheme of applied current cathodic protection of moisture-cured coatings, in which the moisture-cured coating is a two-component high-solid polyamine adduct cured epoxy paint. In this example, PPG of Pompej Coatings (Kunshan) Co., Ltd. is selected. Wear-resistant epoxy paint 880. The moisture-curing paint is first coated on the test piece, and the thickness gauge is measured to meet the requirements of the scheme. The test piece is hung on the auxiliary navigation wall upstream of Gezhouba No. 2 ship lock, on the side of the sand flushing sluice, and the potential data is measured with a portable copper sulfate reference electrode.

[0032] PPG paint St2: The paint surface is normal, without bubbling or chapping damage, and there are white fine sand particles attached to the scribed position. After cleaning, the silver metal substrate can be seen, and no rust is found on the exposed position, such as figure 1 Left ha...

Embodiment 2

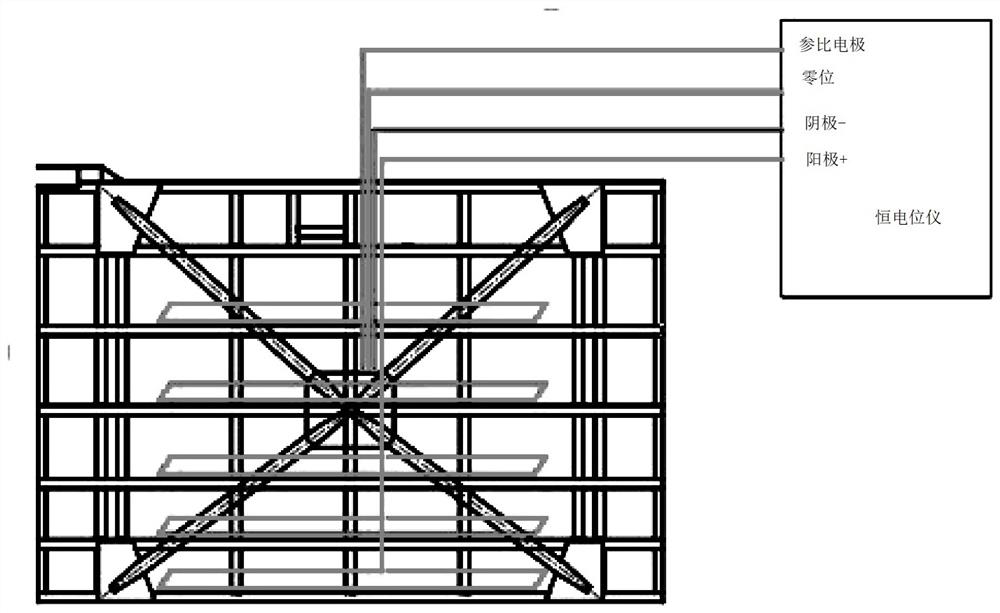

[0037] Comprehensive anti-corrosion test of ship lock metal structure

[0038] The anti-corrosion coating of the upstream gate of a certain ship lock is poor. A prototype test was carried out on the upstream gate of the ship lock. On the basis of the original coating, impressed current cathodic protection was added, and the research work of coating-impressed current cathodic protection test was carried out.

[0039] During the specific construction, the steps are:

[0040] S1. Carry out surface pretreatment on the metal structure of the miter door, and clean up attachments, rust and other impurities; during surface pretreatment, wet sandblasting or high-pressure water is used for surface pretreatment, and the water produced is equipped with water retaining facilities and filtering facilities On-site recovery filtration and secondary use.

[0041] S2. Paint anti-corrosion Spray moisture-curing paint on the metal structure of the miter door, and the spraying amount is 0.45L / m p...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com