Wind turbine blade leading edge protection material and preparation method and application thereof

A technology for wind power blades and protective materials, applied in wind power generation, mechanical equipment, wind turbines, etc., can solve problems such as heavy workload, easy damage to protective film, poor surface viscosity, etc., to solve the problem of short service life, effective application, The effect of improving the bonding performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

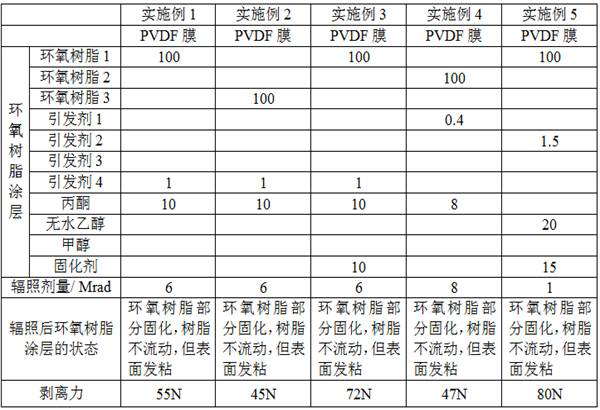

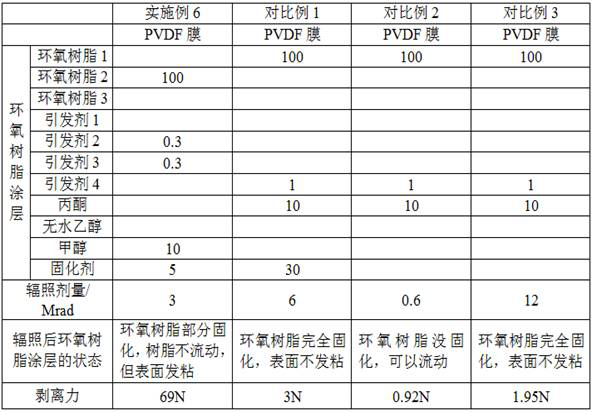

[0023]The present invention will be described in detail below with reference to the specific embodiments. The following examples will help to further understand the present invention in any form of technicrat, it will be further understood by those skilled in the art. It should be noted that several deformations and improvements can be made without departing from the concept of the present invention without departing from the present invention. These are all of the scope of protection of the present invention.

[0024]The raw materials used in the context of the context and the proportion are from the market, but are not limited to these materials:

[0025]Epoxy resin 1: epoxy value is 0.52;

[0026]Epoxy resin 2: The epoxy value is 0.44;

[0027]Epoxy resin 3: The epoxy value is 0.35;

[0028]Curing agent: diethyl am amine;

[0029]The initiator 1: 4,4'-dimethyl diphenyl iodonium hexafluorophosphate;

[0030]Entraithm 2: diphenyl iodononium hexafluorophosphate;

[0031]Entraithm 3: Double (4-tert-butylben...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| epoxy value | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com