Salt spray anti-rust oil containing organic amine-carboxylate compound and its preparation method and application

A carboxylate and organic amine technology, applied in the field of salt spray-resistant antirust oil and its preparation, can solve the problems of increasing process equipment, operation and product cost, power consumption, etc., and achieves clear and transparent appearance, thick barrier film, good quality The effect of the anti-corrosion effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example 1

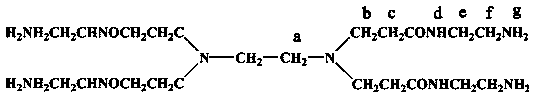

[0039] Preparation Example 1: Containing Organic Amine-Carboxylate Compound Additives

[0040] (1) First, mix 3 parts by weight of ethylenediamine, 34 parts by weight of methyl acrylate, and 9 parts by weight of methanol into the reactor A, and react at 20°C for 4 hours to obtain a spare solution

[0041] (2) Take out 1 part by weight from the standby solution obtained in step (1), mix it with 2 parts by weight of methanol and 3 parts by weight of ethylenediamine and add it to the reactor A, react at 30°C for 8 hours, and distill under reduced pressure Obtain viscous sample containing organic amine;

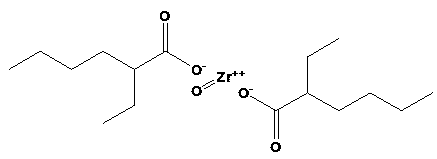

[0042] (3) After mixing 1.4 parts by weight of isooctanoic acid, 3.3 parts by weight of D40 solvent oil and 4 parts by weight of sodium hydroxide, they were added to reactor B, and reacted at 60° C. for 20 minutes.

[0043] (4) In the reactor B of step (3), add zirconium oxychloride with a weight ratio of 6:1.4 to isooctanoic acid (referring to zirconium oxychloride: isooctanoic...

Embodiment 1

[0046] (1) Add 44 parts by weight of 15# mechanical oil and 40 parts by weight of D40 solvent oil into the reaction kettle D and heat and stir. When heating to 100°C, add 1 part by weight of the organic amine-carboxylate prepared in the above Preparation Example 1 Compound additive, react for 10 minutes;

[0047] (2) Reduce the temperature of the system in step (1) to 60°C, add 3.5 parts by weight of N-oleoyl sarcosine, 2 parts by weight of T743 oxidized petroleum grease barium soap, and 3 parts by weight of high alkali value calcium petroleum sulfonate, and continue stirring Until it is completely dissolved, it is cooled to room temperature to obtain a salt spray anti-rust oil containing an organic amine-carboxylate compound.

preparation example 2

[0048] Preparation Example 2: Containing Organic Amine-Carboxylate Compound Additives

[0049] (1) First, mix 3 parts by weight of ethylenediamine, 34.3 parts by weight of methyl acrylate, and 9.5 parts by weight of methanol into the reactor A, and react at 25°C for 4.5 hours to obtain a spare solution

[0050] (2) Take 1 part by weight from the standby solution obtained in step (1), mix it with 2.5 parts by weight of methanol and 3.3 parts by weight of ethylenediamine, add it to the reactor A, react at 35°C for 8.5 hours, and distill under reduced pressure Finally, a viscous sample containing organic amines is obtained;

[0051] (3) Mix 1.5 parts by weight of isooctanoic acid, 4.2 parts by weight of D40 solvent naphtha, and 4.3 parts by weight of sodium hydroxide, and then add them to the reactor B, and react at 65° C. for 30 minutes.

[0052] (4) Add zirconium oxychloride with a weight ratio of 6.5:1.5 to isooctanoic acid in reaction kettle B of step (3), react at 75°C for ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com