A kind of nodular cast iron pipe with waterproof protective layer and its production process

A nodular cast iron pipe, production process technology, applied in the direction of pipeline anti-corrosion/rust protection, damage protection, pipeline protection, etc., can solve the problems of no cathodic protection function, poor surface hardness, weak destructive resistance, etc., to reduce the project life Cycle cost, good corrosion resistance, strong damage resistance effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment

[0011] A specific embodiment of the production process of a ductile iron pipe with a waterproof protective layer according to the present invention is as follows:

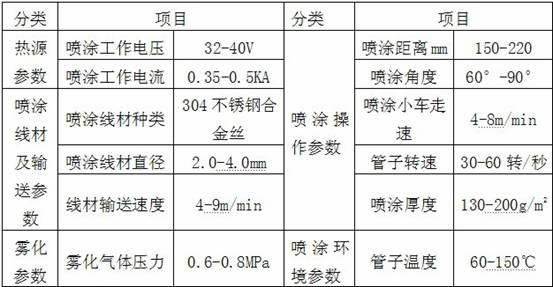

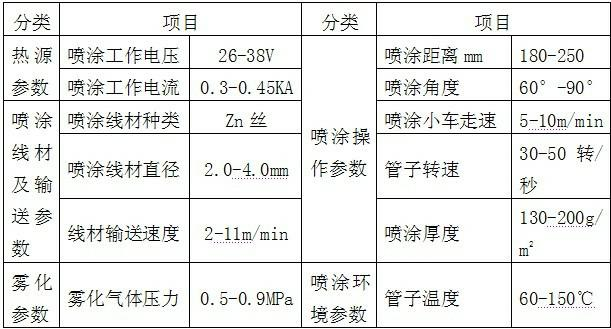

[0012] (1) Surface treatment: First, the air compressor provides shot blasting and sandblasting power. In the shot blasting chamber, the iron sand with uniform particle size is impacted on the surface of the ductile iron pipe at high speed under the action of compressed air to remove the rust and other oxides on the surface of the substrate. , Reaching the Sa2.5 level, thoroughly removing oxide scale, iron beans, warped skin, oil, grease, asphalt, rust, etc., to provide a clean surface for the spray coating. Spraying within 4 hours after shot blasting. Before spraying, use nitrogen or dry and clean compressed air to blow the outer surface of the ductile iron pipe to remove impurities such as floating dust. In short, before spraying, no water is allowed on the surface of the pipe to be sprayed. , Grease, dust and other...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com