Front edge protection wind power blade and forming method thereof

A technology of wind power blades and forming methods, which is applied to wind power generation, wind engines consistent with the wind direction, wind engines, etc., can solve the problems of short protection period, complicated construction process, and long operation time, so as to prolong the protection period and enhance The effect of simple blade structure and molding process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

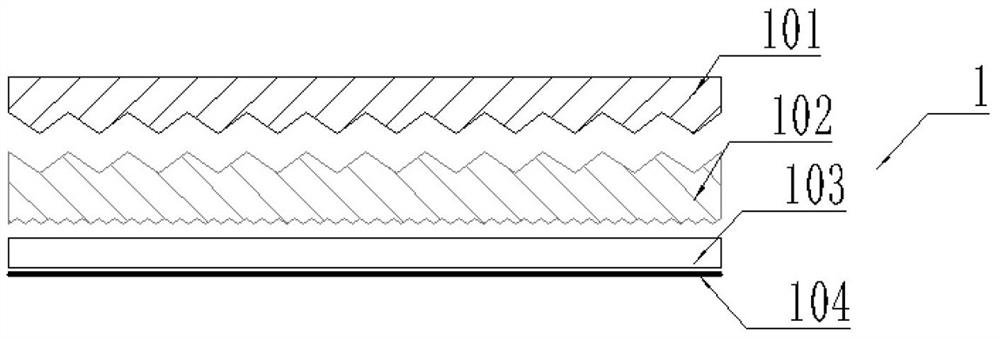

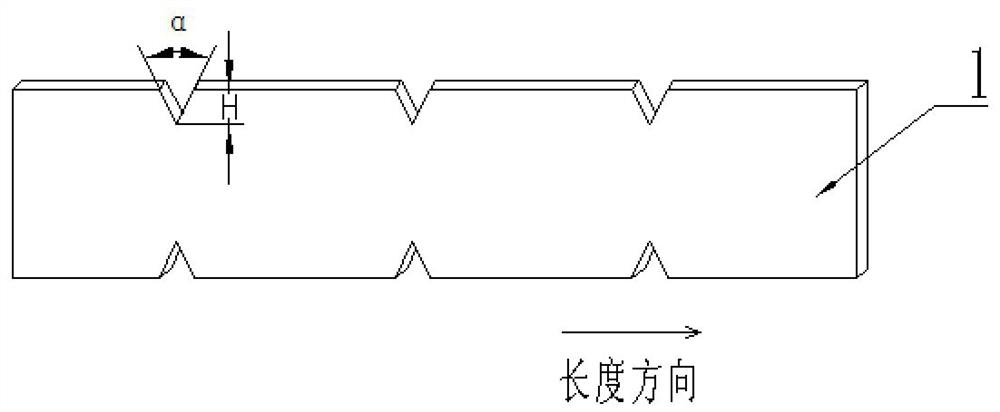

[0042] The present invention provides a wind power blade with leading edge protection, and the leading edge of the blade is provided with a leading edge protection film 1 (such as figure 1 shown), the leading edge protective film 1 is a multi-layer structure, including a protective layer 101, a buffer layer 102 and an adhesive layer 103 in sequence from the outside to the inside.

[0043] The protective layer 101 is a polytetrafluoroethylene filled with graphite reinforcing agent or a polymer modified material with the same performance, which has good rigidity, wear resistance, corrosion resistance, is convenient to resist rain erosion, and has electrical conductivity.

[0044] The buffer layer 102 is a high-elasticity polyurethane foam or a high-density elastic foam with the same performance, which has high elasticity, wear resistance, and high elongation, and is convenient for absorbing the impact energy of rainwater.

[0045] The adhesive layer 103 is a glass fiber tape, an...

Embodiment 2

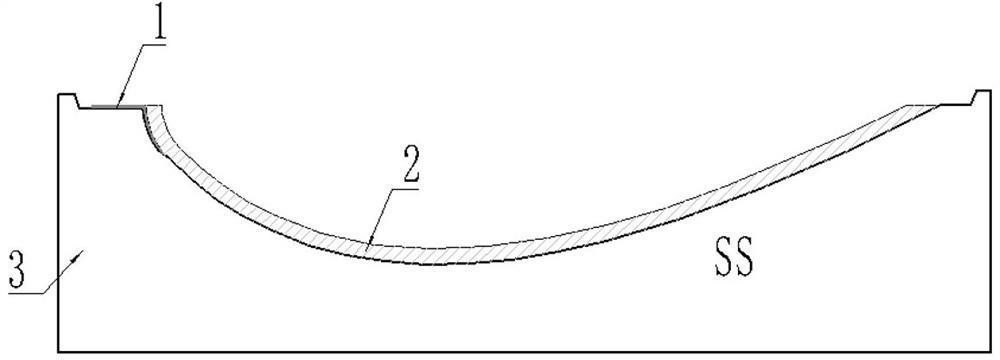

[0061] The present invention provides another method for forming a wind power blade with leading edge protection. The leading edge protection film 1 is pasted on the shaped and demolded blade. Figure 7 shown, the specific steps are as follows:

[0062] (1) After the blade is demolded, mark the leading edge bonding area 8 of the protective film on the leading edge of the blade;

[0063] (2) Grind the front edge bonding area 8, and clean it up after grinding;

[0064] (3) Scrape a layer of resin on the leading edge bonding area, then tear off the leading edge protective film release paper 104 and directly stick it on the leading edge bonding area 8 of the blade, and flatten it with a scraper;

[0065] (4) After curing, seal the edges of the protective film 1 on the SS surface of the blade and the front edge of the blade PS with a sealant 7.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com