Echelon releasing method for underground solid anticorrosion and antiscale agents

A kind of anti-scaling agent and solid technology, applied in chemical instruments and methods, earthwork drilling, wellbore/well components, etc., can solve problems such as difficult to improve and prolong pump inspection period

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

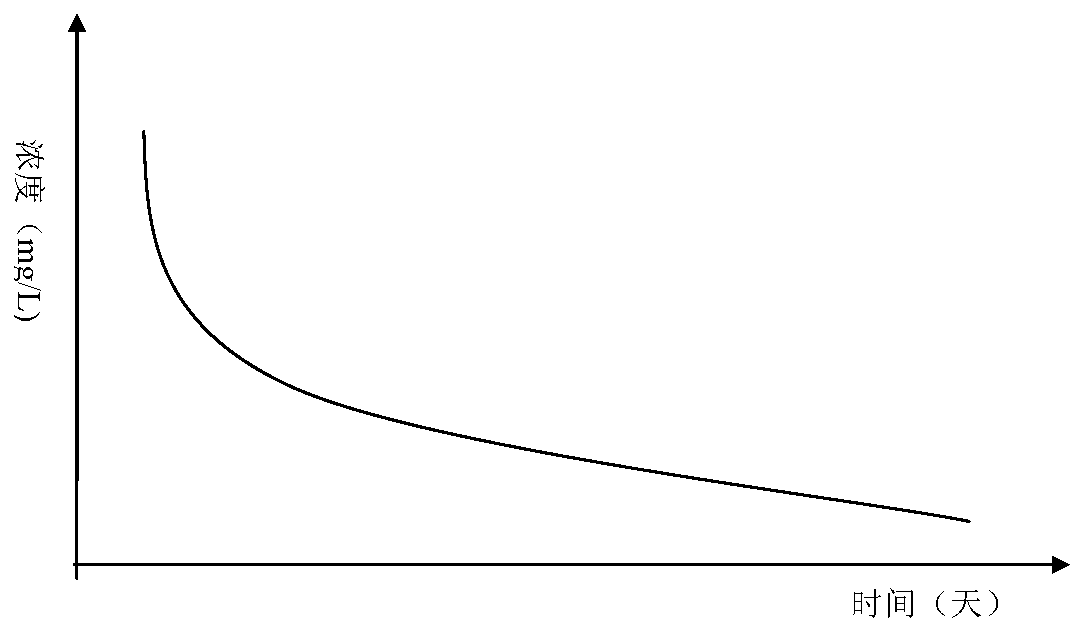

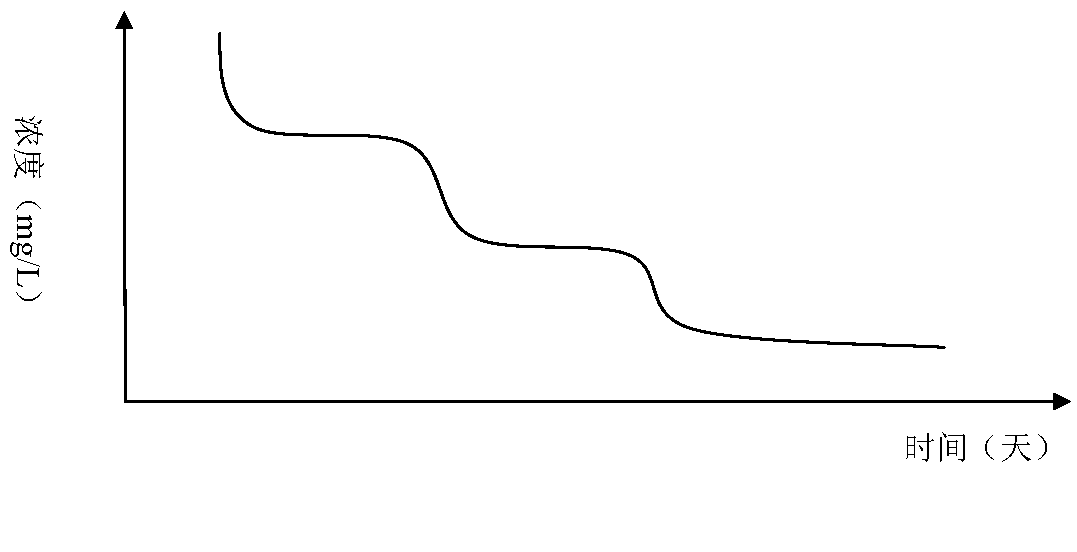

Image

Examples

Embodiment 1

[0023] In an oilfield operation area of Xinjiang Oilfield Company, the pump hanging depth is 2135.94 meters, the well temperature is 71 degrees, the liquid production rate is 5 cubic meters per day, and the water content is 60%. The calcium loss rate is 9.6%, the total iron content is 27mg / L, and the corrosion and scaling are serious; at this time, the screen tube is used, and the solid anti-corrosion and anti-scaling agent 1 is added, and the dosage is 90Kg, and then the screen tube is suspended under the pump. After the implementation, the calcium loss rate of water in the produced fluid was reduced to 1.1%, the total iron content was reduced to 2.1mg / L, the pump inspection cycle was extended to 418 days, and the corrosion and scaling were effectively controlled.

Embodiment 2

[0025] In an oilfield operation area of Xinjiang Oilfield Company, the pump hanging depth is 1704.98 meters, the well temperature is 56 degrees, the fluid production rate is 13.8 cubic meters per day, and the water content is 86%. The calcium loss rate was 20.5%, the total iron content was 10.8mg / L, and the corrosion and scaling were serious; at this time, 120Kg of solid anti-corrosion and anti-scaling agent 1 was added to the wellhead, and the calcium loss rate in the produced fluid was reduced to 3.2% after the measures were implemented. The total iron content was reduced to 1.7mg / L, the pump inspection cycle was extended to 362 days, and the corrosion and scaling were effectively controlled.

Embodiment 3

[0027] In an oilfield operation area of Xinjiang Oilfield Company, the pump hanging depth is 1197.79 meters, the well temperature is 40 degrees, the liquid production rate is 12 cubic meters per day, and the water content is 61%. The calcium loss rate is 15.7%, the total iron content is 18.2mg / L, and the corrosion and scaling are serious. At this time, 120Kg of solid anti-corrosion and anti-scaling agent 2 is added to the wellhead. After the measures are implemented, the calcium loss rate of the water in the produced fluid is reduced to 3.1%. The total iron content was reduced to 2.5mg / L, the pump inspection cycle was extended to 371 days, and the corrosion and scaling were effectively controlled.

[0028] The dissolution rate that the present invention adopts is 0.12g / cm 2 The imidazoline corrosion inhibitor of *h can be obtained by the following method:

[0029] Add 0.2mol naphthenic acid (molecular weight 180-200) and 41.6g (0.22moL) tetraethylenepentamine to the three-n...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com