High-strength bolt friction-type connecting structure and connection node performance optimizing method thereof

A technology of high-strength bolts and connecting structures, applied in building components, building structures, building insulation materials, etc., can solve the problems of insufficient shear bearing capacity, long-term maintenance, poor corrosion resistance, etc., to increase the friction coefficient and The effect of anti-slip coefficient, improving shear bearing capacity and firm bonding strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

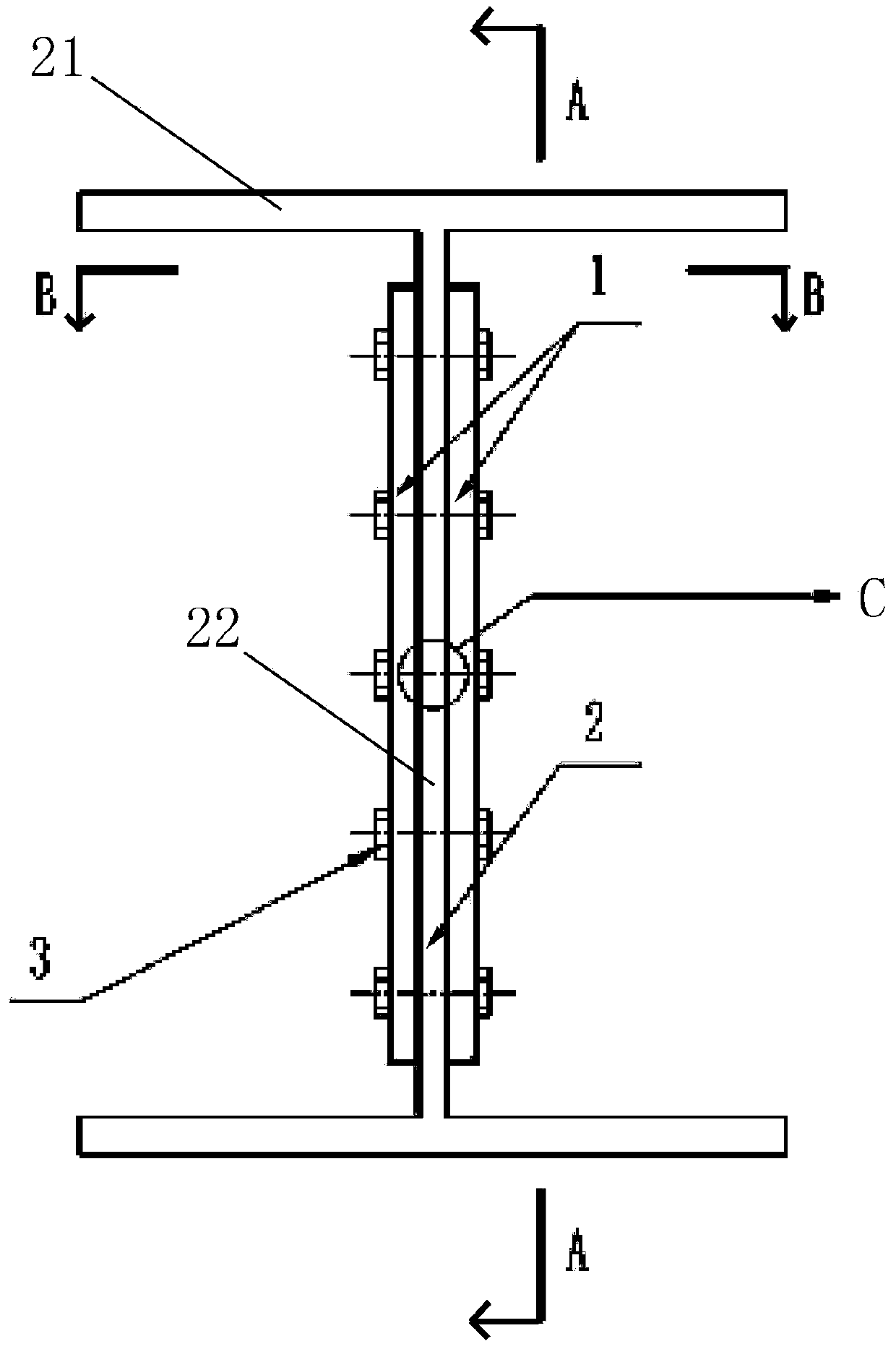

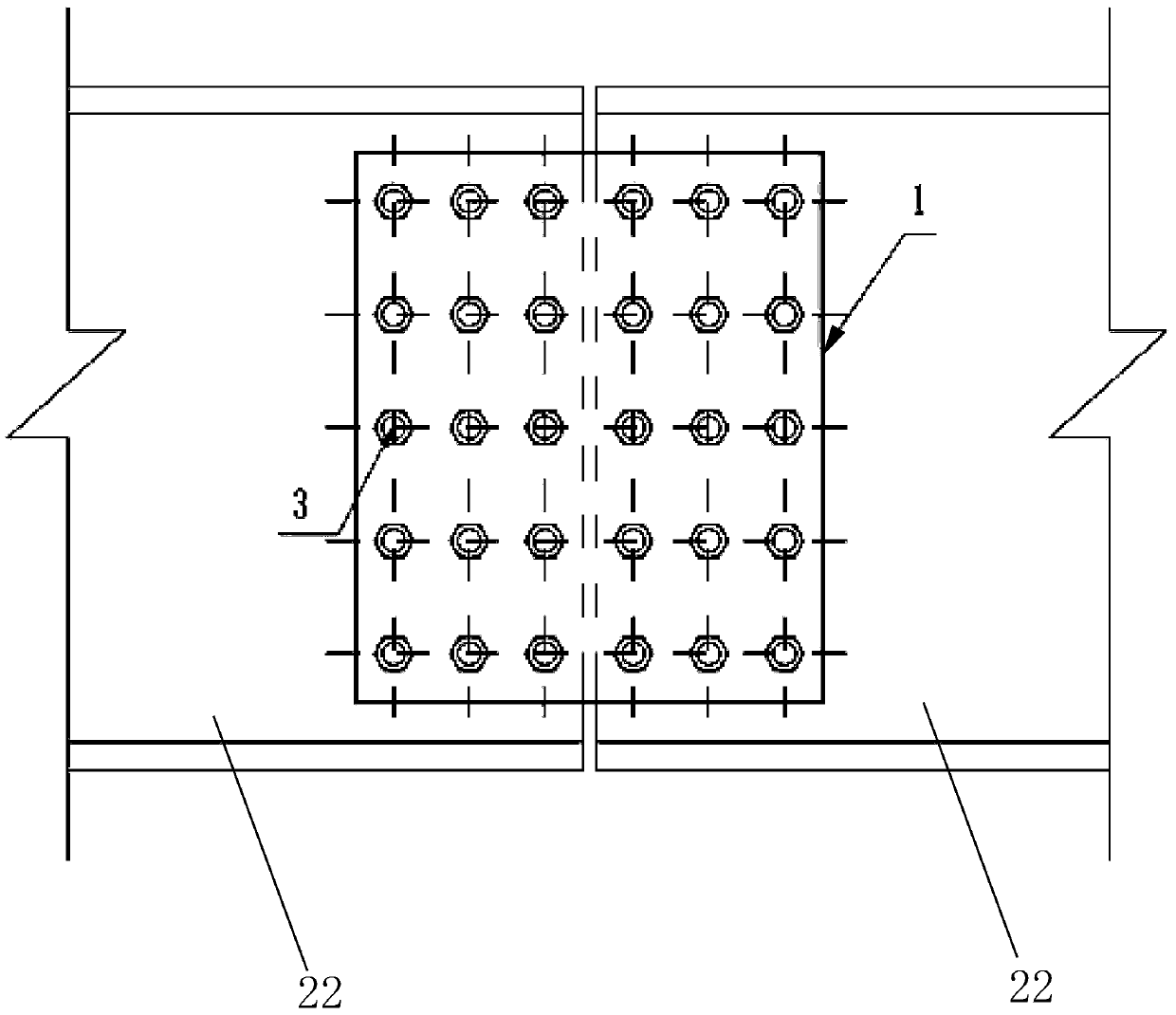

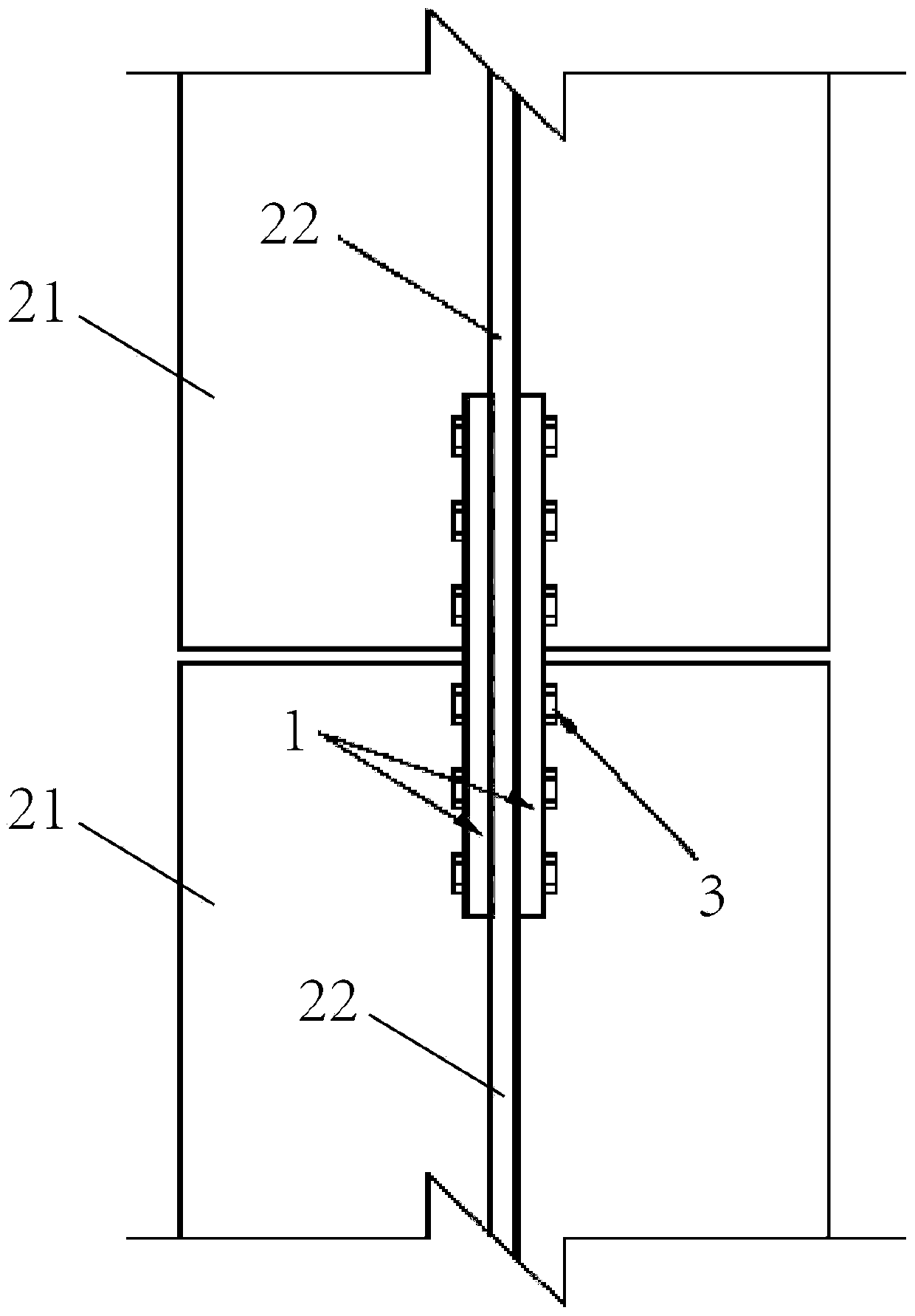

[0021] Such as Figure 1 to Figure 4 As shown, it is a preferred embodiment of the high-strength bolt friction connection structure in the present invention, and the high-strength bolt friction connection structure includes several steel beams 2 and connecting cover plates 1 . The outer surface of the connection cover plate 1 is provided with an aluminum-sprayed layer b, and the connection cover plate 1 is respectively fixed on several butt steel beams 2 through bolts 3 .

[0022] In the present embodiment, the steel beam 2 is an I-shaped steel, and its quantity is two. Each steel beam 2 includes a flange 21 and a web 22, and a standard bolt hole is provided on the web 22 at the beam end of the steel beam 2 (in the figure not shown), the joints of the steel beams 2 are provided with a spray paint layer a. The size and thickness of the connecting cover plate 1 is adapted to the web 22 of the steel beam 2, and it is fixed on the web 22 of the two I-shaped steel beams 2 and cove...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com