High-temperature-resisting thermal recovery cement and preparation method thereof

A warm and high-resistant technology, applied in the field of thermal recovery cement and its preparation, can solve the problems affecting the production life of heavy oil thermal recovery wells, high-temperature strength decline, and permeability increase, etc., to achieve strong production controllability and high strength The effect of not fading and overcoming the decline in compressive strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

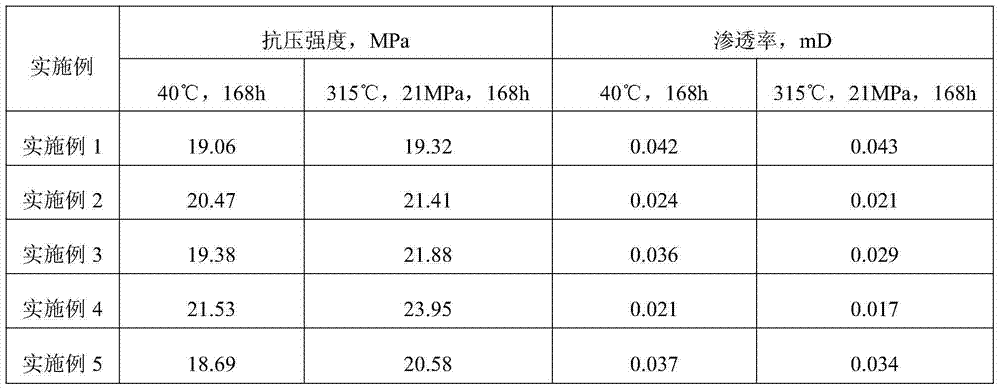

Examples

Embodiment 1

[0019] Weigh 55 parts by weight of aluminate cement clinker, 10 parts by weight of phosphate rock slag, and 30 parts by weight of slag, mix them, and then pour them into a ball mill for grinding. The mixed powder is ground to a Blaine specific surface area of 250m 2 / kg, add 1 weight part of ceramic fiber and 2 weight parts of rubber powder, mix for 10 minutes, and then make hot cement.

Embodiment 2

[0021] Weigh 65 parts by weight of aluminate cement clinker, 30 parts by weight of phosphate rock slag, and 10 parts by weight of slag, mix them, then pour them into a ball mill for grinding, and grind the mixed powder until the Blaine specific surface area is 260m 2 / kg, add 3 parts by weight of ceramic fiber and 3 parts by weight of rubber powder, mix for 10 minutes, and then heat mining cement is made.

Embodiment 3

[0023] Weigh 65 parts by weight of aluminate cement clinker, 30 parts by weight of phosphate rock slag, and 20 parts by weight of slag, mix them, then pour them into a ball mill for grinding, and grind the mixed powder until the Blaine specific surface area is 270m 2 / kg, add 2 parts by weight of ceramic fiber and 2 parts by weight of rubber powder, mix for 10 minutes, and then heat the cement to make it.

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| particle size (mesh) | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com