Anti-collapse tundish smearing material and preparation method thereof

A smear and tundish technology, which is applied in the field of anti-collapse tundish smear and its preparation, can solve problems such as affecting the production arrangement of a steel mill, collapse of the lining of the smear, affecting the quality of molten steel, etc. The effect of excellent construction performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

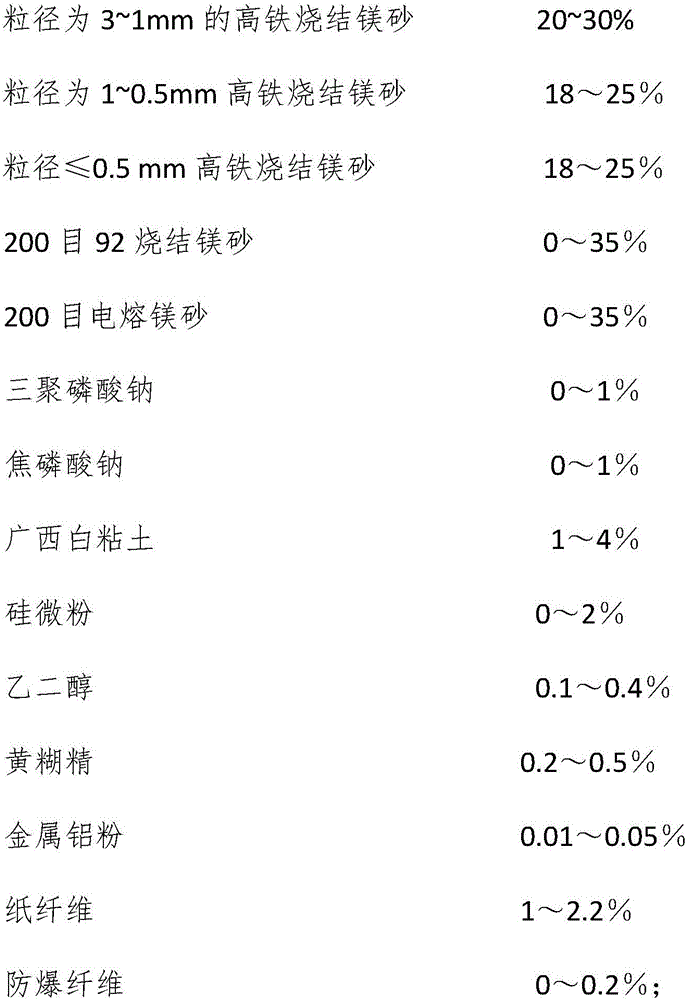

[0024] 1) Formulation:

[0025] 3~1mm high iron sintered magnesia 25%, 1~0.5mm high iron sintered magnesia 20%, 0.5~0mm high iron sintered magnesia 20%, 200 mesh 92 sintered magnesia 30%, sodium tripolyphosphate 0.5%, sodium pyrophosphate 0.5%, Guangxi white clay 1%, silica powder 1%, ethylene glycol 0.15%, yellow dextrin 0.4%, metal aluminum powder 0.01%, paper fiber 1.5%, explosion-proof fiber 0.1%.

[0026] 2) Preparation method:

[0027] (1) Sodium tripolyphosphate, sodium pyrophosphate, Guangxi white clay, silicon micropowder, yellow dextrin, metal aluminum powder, etc. weighed according to the formula are added to a small mixer and mixed for 20 to 30 minutes. The lined woven bag is called mixed powder.

[0028] (2) Weigh 3~1mm, 1~0.5mm, 0.5~0mm magnesia raw materials according to the formula, add them into the forced mixer and stir for about 1 minute. Then add the weighed liquid ethylene glycol and mix for about 2 minutes, and mix well so that the liquid ethylene glyc...

Embodiment 2

[0030] 1) Formulation:

[0031] 30% of 3-1mm high-speed iron sintered magnesia, 20% of 1-0.5mm high-speed iron sintered magnesia, 20% of 0.5-0mm high-speed iron sintered magnesia, 24% of 200 mesh 92 sintered magnesia, 0.25% of sodium tripolyphosphate, sodium pyrophosphate 0.25%, Guangxi white clay 3%, silica powder 1%, ethylene glycol 0.1%, yellow dextrin 0.5%, metal aluminum powder 0.015%, paper fiber 1%, explosion-proof fiber 0.1%.

[0032] 2) Preparation method:

[0033] (1) Sodium tripolyphosphate, sodium pyrophosphate, Guangxi white clay, silicon micropowder, yellow dextrin, metal aluminum powder, etc. weighed according to the formula are added to a small mixer and mixed for 20 to 30 minutes. The lined woven bag is called mixed powder.

[0034] (2) Weigh 3~1mm, 1~0.5mm, 0.5~0mm magnesia raw materials according to the formula, add them into the forced mixer and stir for about 1 minute. Then add the weighed liquid ethylene glycol and mix for about 2 minutes, and mix well...

Embodiment 3

[0036] 1) Formulation:

[0037] 3~1mm high iron sintered magnesia 23%, 1~0.5mm high iron sintered magnesia 22%, 0.5~0mm high iron sintered magnesia 18%, 200 mesh fused magnesia 31%, sodium tripolyphosphate 0.6%, Guangxi white clay 1%, silicon micropowder 2%, ethylene glycol 0.2%, yellow dextrin 0.4%, metal aluminum powder 0.01%, paper fiber 1.2%, explosion-proof fiber 0.15%.

[0038] 2) Preparation method:

[0039] (1) Sodium tripolyphosphate, Guangxi white clay, silicon micropowder, yellow dextrin, metal aluminum powder, etc. weighed according to the formula are added to a small mixer and mixed for 20 to 30 minutes, and the mixed material is loaded into a plastic-lined braided It is reserved in the bag and is called mixed powder.

[0040] (2) Weigh 3~1mm, 1~0.5mm, 0.5~0mm magnesia raw materials according to the formula, add them into the forced mixer and stir for about 1 minute. Then add the weighed liquid ethylene glycol and mix for about 2 minutes, and mix well so that t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com