Method for producing sintered ore, method for producing raw material for sintering, granulated pellet, and sintered ore

A manufacturing method and technology of sintered ore, applied in the manufacture of sintered ore, the manufacture of raw materials for sintering, granulation particles and the field of sintered ore, can solve the problems that the improvement effect of low-temperature strength is not obvious, achieve good low-temperature air permeability, and improve the production efficiency. Granularity, strength-enhancing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 approach

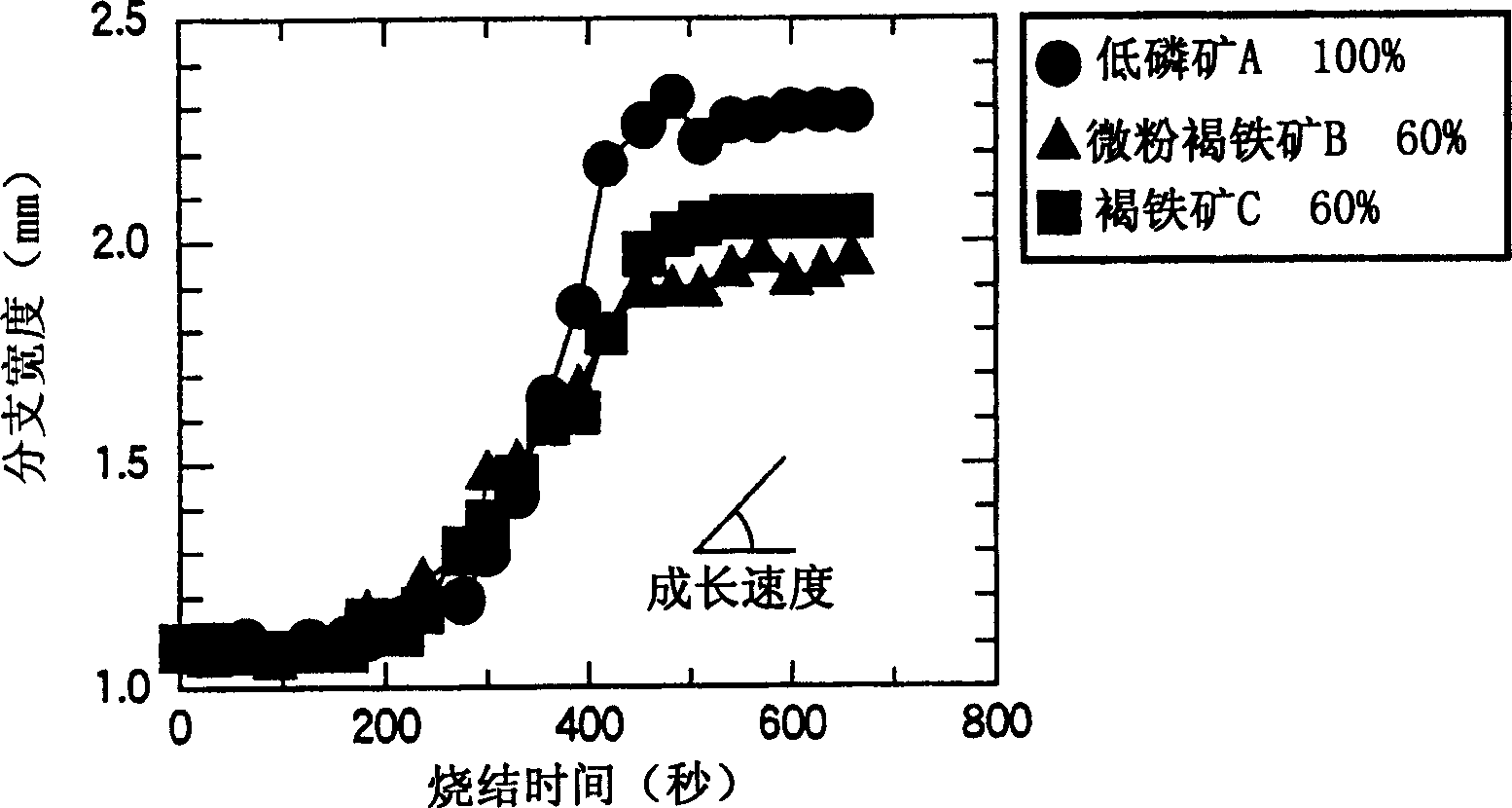

[0110] Figure 16 Indicates the measurement results of the low-temperature strength and reduction powderability of the sintered body. It can be seen that, by adopting the production method of this embodiment, the low-temperature strength is good, and the strength after reduction can be improved. Table 5 shows the use of Figure 15 The results of sintering experiments were carried out on the granulated particles manufactured by the method. From this, it can be seen that by adopting the method of the present invention (first embodiment: granulation experiment No. 3), productivity, low-temperature strength (shutter strength, reduced pulverization (RDI)), and yield can be improved at the same time.

[0111] Experiment No.

No.1

No.2

No.3

Granulation method

Uniform granulation

External granulation type

first embodiment

Average wind speed (m / s)

3.19

3.36

4.32

Yield(%)

81.1

76.7

78.6

Sh...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com