Alkaline sliding plate for continuous casting of special steel and preparation process thereof

A special steel and continuous casting technology, applied in the direction of manufacturing tools, casting equipment, metal processing equipment, etc., can solve the problems of poor Ca corrosion resistance and difficulty in adapting, and achieve the goal of enhancing corrosion resistance, reducing carbon content, and improving strength Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

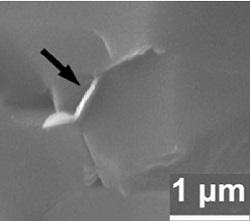

Image

Examples

Embodiment 1

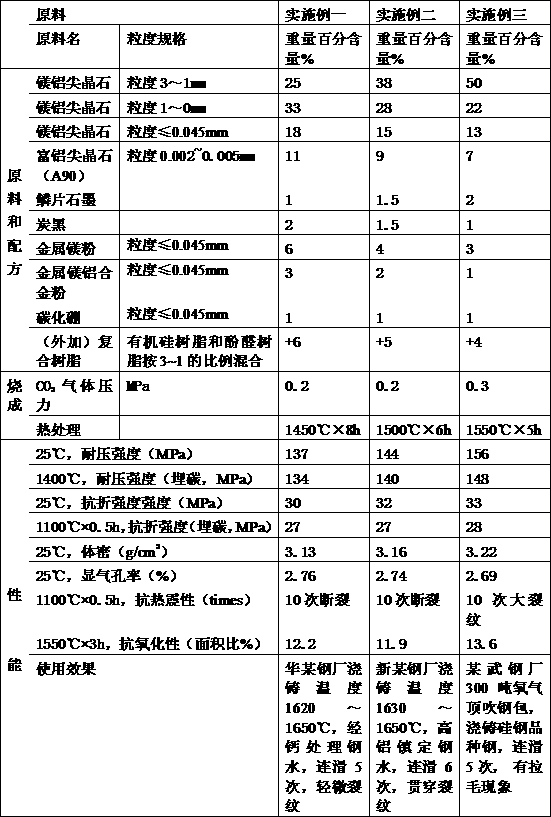

[0030] Raw material specifications and formula (weight percentage) are as follows:

[0031] (1) Magnesium-aluminum spinel with a particle size of 3-1mm, 25%;

[0032] (2) Magnesium-aluminum spinel with a particle size of 1-0mm, 33%;

[0033] (3) Magnesium-aluminum spinel with particle size ≤0.045mm, 18%;

[0034] (4) Aluminum-rich spinel (A90) with a particle size of 0.002~0.005mm, 11%;

[0035] (5) Flake graphite, 1%;

[0036] (6) Carbon black, 2%;

[0037] (7) Metal magnesium powder with particle size ≤0.045mm, 6%;

[0038] (8) Magnesium-aluminum alloy powder with particle size ≤0.045mm, 3%;

[0039] (9) Boron carbide with particle size ≤0.045mm, 1%;

[0040] (10) Additional composite resin, +6%;

[0041] (11) Carbon dioxide gas.

[0042] Raw material (10) composite resin is added separately, not included in the total mass percentage of raw materials. The composite resin is made by mixing silicone resin and phenolic resin in a ratio of 3:1. Raw material (11) carbon...

Embodiment 2

[0056] Raw material specifications and formula (weight percentage) are as follows:

[0057] (1) Magnesium-aluminum spinel with a particle size of 3-1mm, 38%;

[0058] (2) Magnesium-aluminum spinel with a particle size of 1-0mm, 28%;

[0059] (3) Magnesium-aluminum spinel with particle size ≤0.045mm, 15%;

[0060] (4) Aluminum-rich spinel (A90) with a particle size of 0.002~0.005mm, 9%;

[0061] (5) Flake graphite, 1.5%;

[0062] (6) Carbon black, 1.5%;

[0063] (7) Metal magnesium powder with particle size ≤0.045mm, 4%;

[0064] (8) Metal magnesium aluminum alloy powder with particle size ≤0.045mm, 2%;

[0065] (9) Boron carbide with particle size ≤0.045mm, 1%;

[0066] (10) Additional composite resin, +5%;

[0067] (11) Carbon dioxide gas.

[0068] Raw material (10) composite resin is added separately, not included in the total mass percentage of raw materials. The composite resin is made by mixing silicone resin and phenolic resin in a ratio of 2:1. Raw material (1...

Embodiment 3

[0081] Raw material specifications and formula (weight percentage) are as follows:

[0082] (1) Magnesium-aluminum spinel with a particle size of 3-1mm, 50%;

[0083] (2) Magnesium-aluminum spinel with a particle size of 1-0mm, 22%;

[0084] (3) Magnesium-aluminum spinel with particle size ≤0.045mm, 13%;

[0085] (4) Aluminum-rich spinel (A90) with a particle size of 0.002~0.005mm, 7%;

[0086] (5) Flake graphite, 2%;

[0087] (6) Carbon black, 1%;

[0088] (7) Metal magnesium powder with particle size ≤0.045mm, 3%;

[0089] (8) Metal magnesium aluminum alloy powder with particle size ≤0.045mm, 1%;

[0090] (9) Boron carbide with particle size ≤0.045mm, 1%;

[0091] (10) Additional composite resin, +4%;

[0092] (11) Carbon dioxide gas.

[0093] Raw material (10) composite resin is added separately, not included in the total mass percentage of raw materials. The composite resin is made by mixing silicone resin and phenolic resin in a ratio of 2:1. Raw material (11) c...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com