Low-cost high-strength high-temperature-resistant coating material and preparation method thereof

A smear, low-cost technology, applied in the field of refractory materials, can solve the problem of inversion of cost and price, and achieve the effect of reducing the cost of ingredients, reducing costs, and improving low-temperature strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

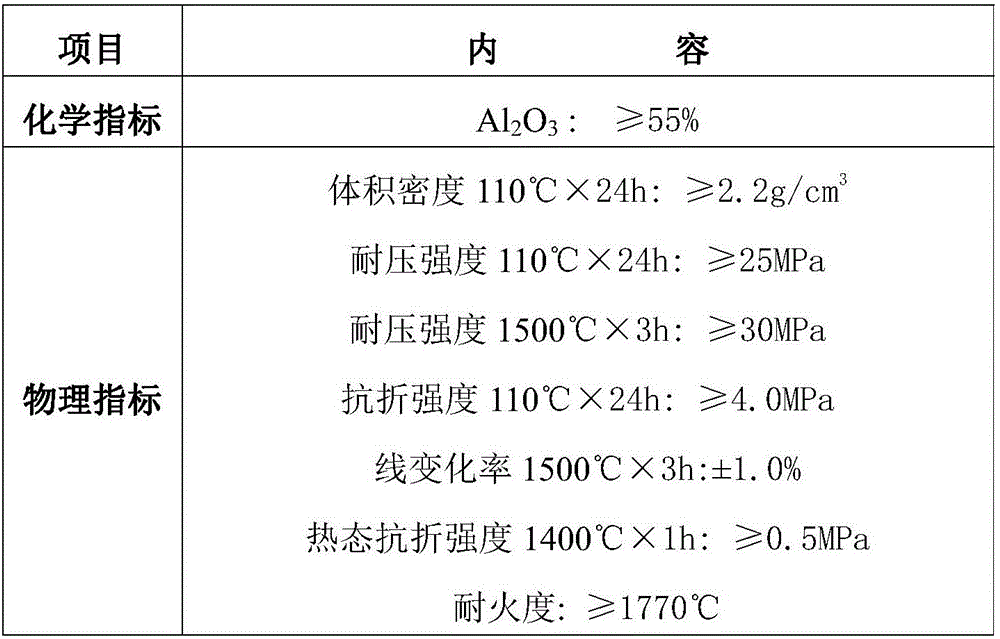

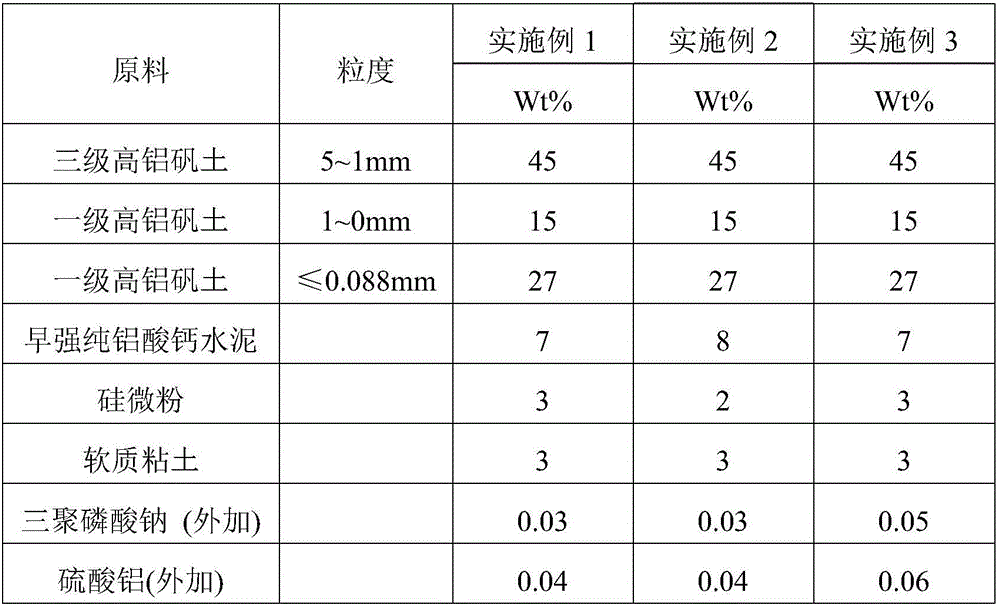

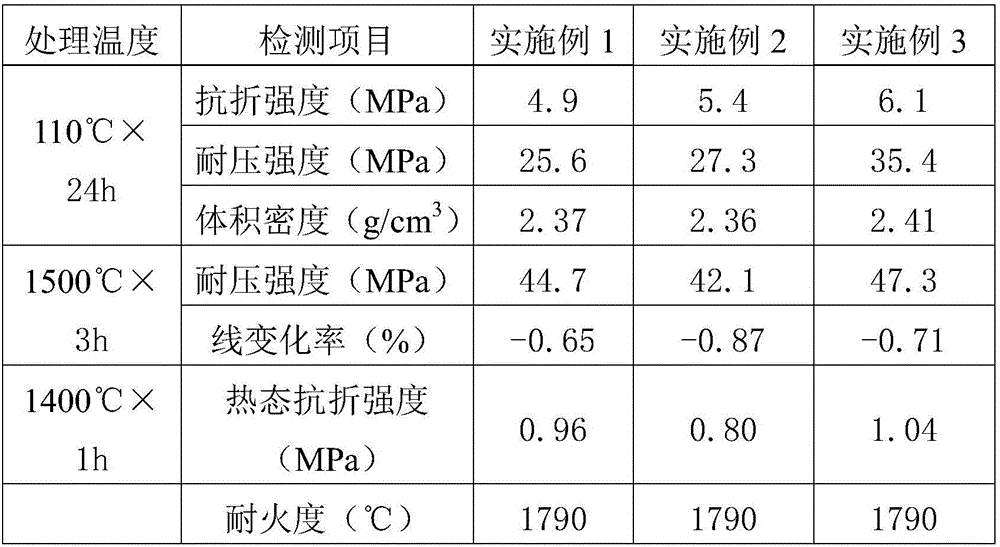

[0036] Specific Examples 1-3 of the components of the present invention are shown in Table 2

[0037] Table 2 Proportion of low-cost, high-strength, high-temperature coating

[0038]

[0039] The origin of the early-strength pure calcium aluminate cement is Kaifeng, Henan, with Al2O3≥71%, and the origin and composition of other raw materials are the same as above.

[0040] ①Sampling method

[0041] Ingredients: Ingredients according to the ratio in Table 2 above, and mix them evenly in the mixing pot.

[0042] Sample preparation: add 11.5% (wt) water, stir in a stirring pot for about 2 to 3 minutes, vibrate and cast to make a sample of 160×40×40mm, natural curing for 1 day after demoulding.

PUM

| Property | Measurement | Unit |

|---|---|---|

| flexural strength | aaaaa | aaaaa |

| compressive strength | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com