Glass lubricant for hot extrusion of titanium and titanium alloy as well as preparation method and application of glass lubricant

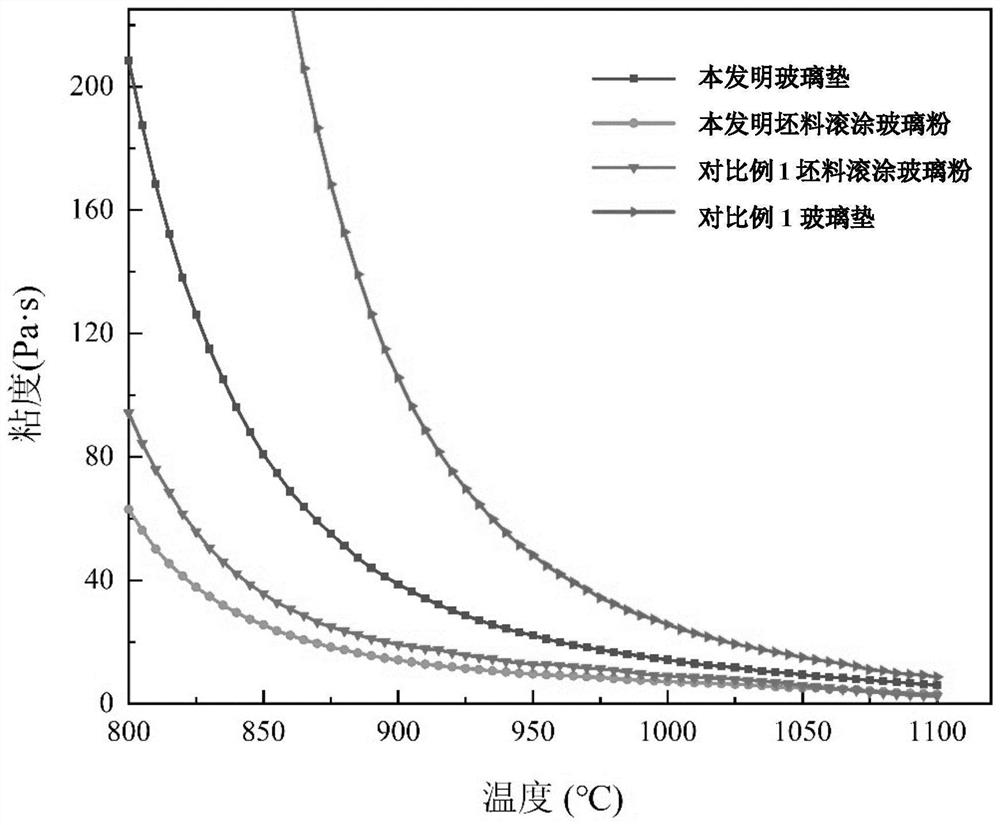

A technology for glass lubricants and titanium alloys, applied in lubricating compositions, additives, petroleum industry, etc., can solve problems such as small applicable temperature range, and achieve the effects of rapid melting, low viscosity, and improved lubricating effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0034] See Table 1 and Table 3 for examples of the composition of the blank roll-coated glass powder, and see Table 2 and Table 4 for examples of the composition of the glass pad (because the impurities and components contained in each raw material are different, such as dolomite containing more than 20% of MgO , less than 32% of CaO, so the composition and ratio of raw materials will cause a certain deviation in the actual effect of the lubricant).

[0035] Table 1 Example of composition of blank roll-coated glass powder (wt.%)

[0036]

[0037] Table 2 Example of glass mat composition (wt.%)

[0038]

[0039]

[0040] Table 3 Raw Material Ratio Example of Blank Roll-coated Glass Powder (wt.%)

[0041]

[0042] Table 4 Raw Material Proportion Example of Glass Mat (wt.%)

[0043]

[0044]

[0045] In the above Tables 1 to 4, in each example, the blank roll-coated glass powder and the glass mat can be mixed and matched for use.

[0046] In above embodiment,...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Viscosity | aaaaa | aaaaa |

| Viscosity | aaaaa | aaaaa |

| Softening point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com