Production method of metal compounded chromium oxide bricks

A chromium oxide brick and metal composite technology, which is applied in the field of refractory materials, can solve problems such as shortening the service life of refractory materials, affecting the service life of gasifiers, and increasing user burdens, and achieves improved thermal shock stability, excellent spalling performance, and excellent Anti-corrosion effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

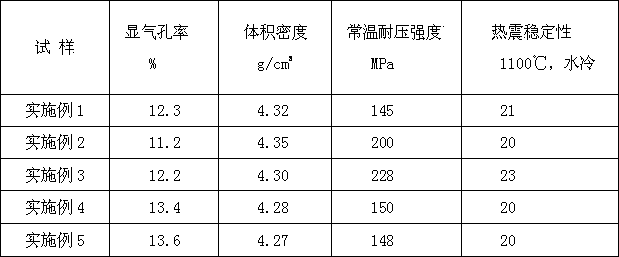

Examples

Embodiment 1

[0017] A method for preparing metal composite chromium oxide bricks, using one or both of fused chromium oxide particles and corundum particles as aggregates, the mass fraction of the aggregate is: 55%-80%, and the mass fraction of the matrix 25-45%, the matrix contains fused chromium oxide fine powder, chromium oxide green, Al 2 o 3 Powder, corundum powder, zirconia powder, the mass fraction of the zirconia powder is 1-10%; add 1% metal silicon, then mix the aggregate in the sand mixer, add 2 / 3 of the binder to mix Mix well, then add the fine powder after co-grinding, mix well, finally add the remaining binder, and mix for about 5 minutes. After trapped material, pressed into green body, dried, fired at 1600-1800℃, reduced or nitrided fired in shuttle kiln, it is obtained.

Embodiment 2

[0019] A method for preparing metal composite chromium oxide bricks, on the basis of the preparation method described in Example 1, adding 0.5% metal chromium.

Embodiment 3

[0021] A method for preparing metal composite chromium oxide bricks. On the basis of the preparation method described in Example 1, 0.2% metal silicon and 0.5% metal aluminum are added.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com