Bag type dust arrest pole electric dust-collecting device

A dust collector and electrostatic precipitator technology, which is used in combination devices, electrostatic effect separation, solid separation, etc., can solve the problems of power supply voltage and electric field strength limitations, complex structure of dust collectors, damage to filter bags, etc., and achieve good dust removal effect. The effect of overcoming the phenomenon of back corona and reducing the amount of steel used

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

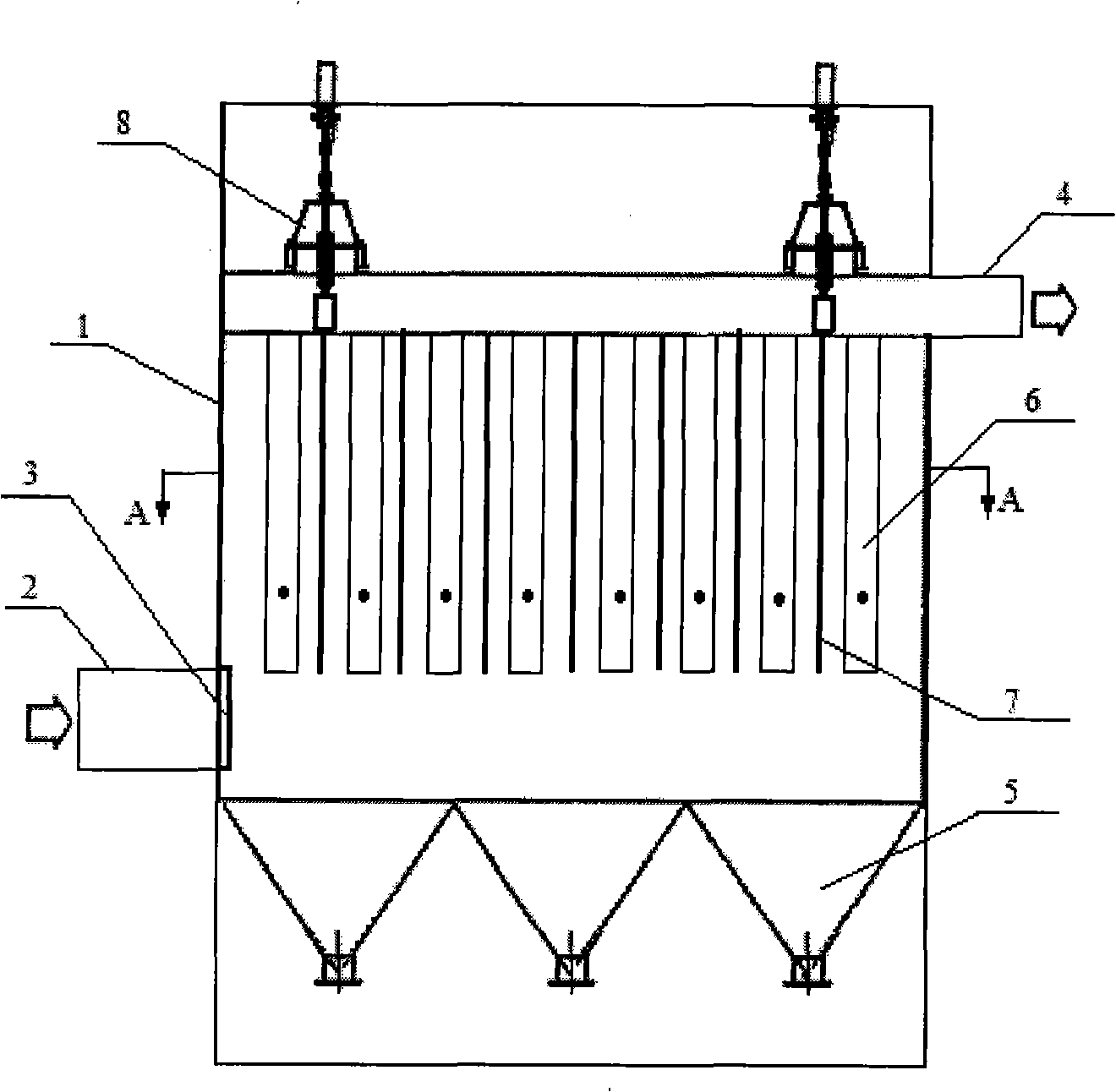

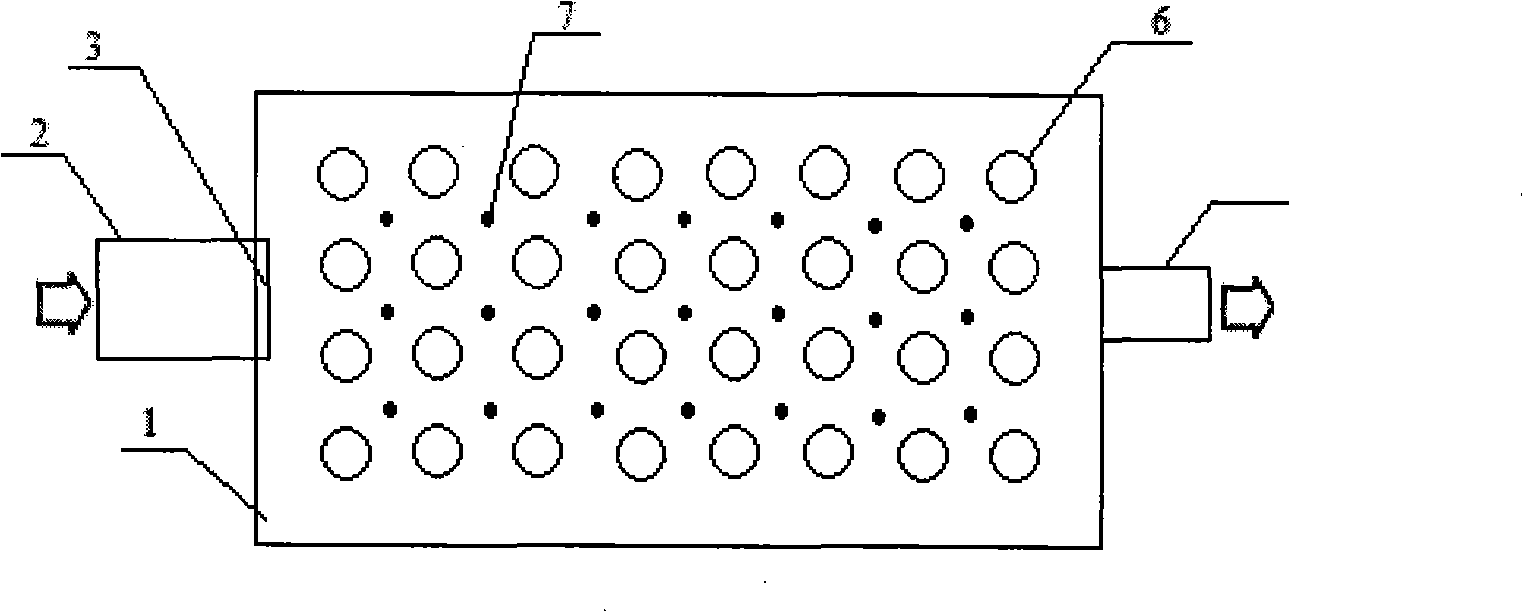

[0011] As shown in the figure, the bag-type dust collector electrostatic precipitator includes a dust collector housing 1, a flue gas inlet 2, an air flow distribution plate 3, a flue gas outlet 4, an ash hopper 5, a filter bag 6, an electrode wire 7 and a high-voltage insulation Room 8; multiple rows of cloth bags 6 are arranged at equal intervals in the housing 1, and high-voltage electrode wires 7 are arranged at the center of each concentric circle of four cloth bags. The high-voltage electrode wires 7 are connected to the power supply through the high-voltage insulation chamber 8 on the top of the dust collector; The side wall of the filter housing 1 is close to the flue gas inlet, and the airflow uniform distribution plate 3 is arranged under the multi-row filter bags 6, and the multi-stage ash hopper 5 is arranged under the multi-row filter bags 6. On the side wall of the dust collector housing 1, the multi-row A flue gas outlet 4 is arranged above the filter bag 6 .

...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com