Resource utilization method for chrome sludge of vanadium extraction waste water treatment sediment

A water treatment and resource utilization technology, applied in the field of solid waste treatment and resource utilization, can solve the problem of lack of low-cost resource utilization methods, and achieve the effect of improving resource utilization efficiency, short process and cost saving

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

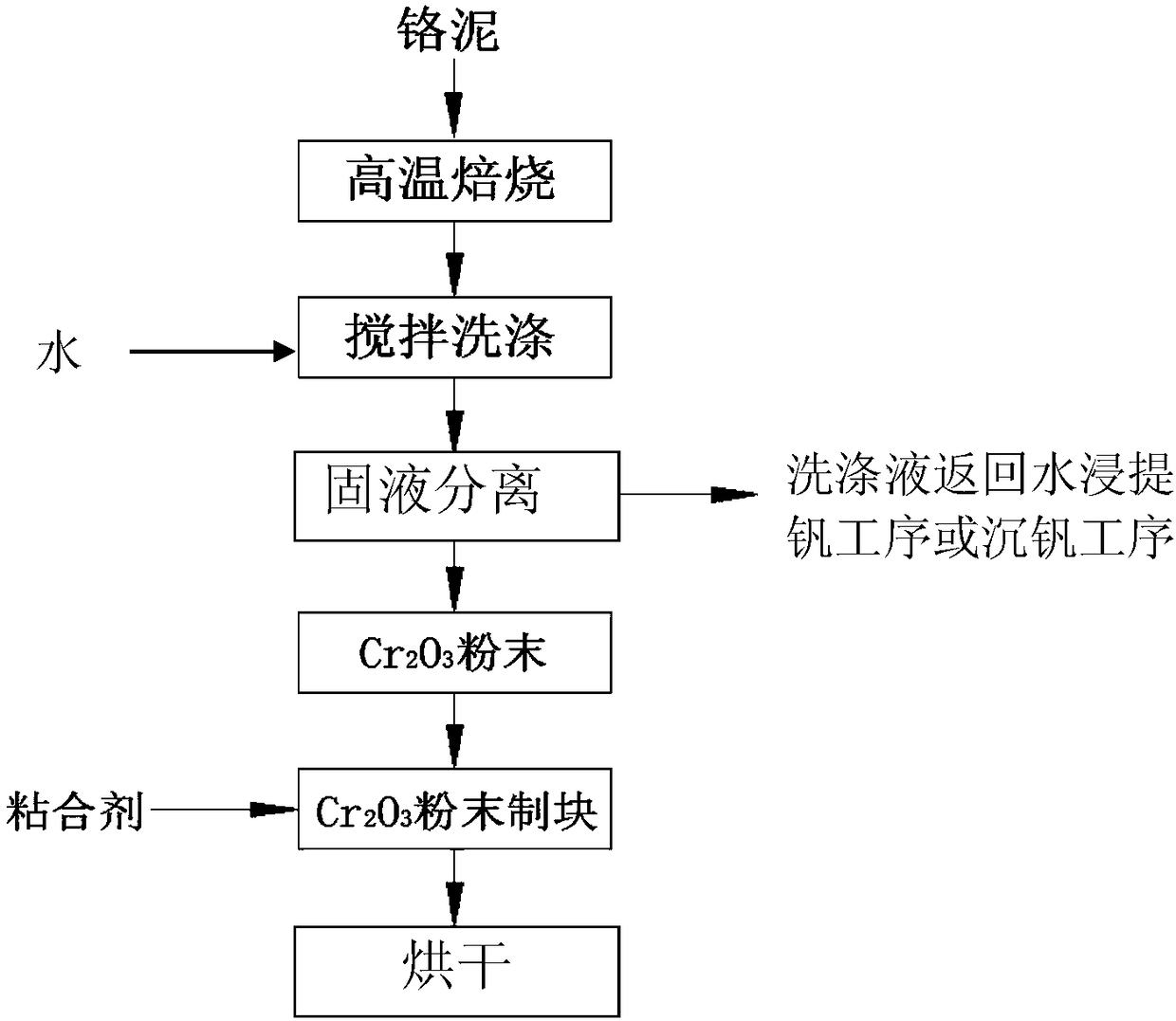

[0029] A method for resource utilization of chrome sludge precipitated by vanadium extraction wastewater treatment, comprising the following steps:

[0030] (1) 250g of vanadium extracting wastewater water treatment precipitated chromium sludge is placed in a muffle furnace for high-temperature roasting, during the roasting process, sodium salt and vanadium remaining in the chromium sludge of vanadium extracting wastewater undergo sodium roasting reaction again to obtain 53g of chromium sludge Roasted product, wherein, Cr in the roasted product 2 o 3 Content 66wt.%; Among them, the high-temperature calcination temperature is 1000 ℃, and the high-temperature calcination time is 2 hours;

[0031] (2) the roasted product is placed in a beaker, water is added, stirred and washed at normal temperature, and the solid-liquid separation obtains the roasted product after washing liquid and washing, and the mass concentration of vanadium in the washing liquid is C V =1.69g / L, reuse af...

Embodiment 2

[0036] A method for resource utilization of chrome sludge precipitated by vanadium extraction wastewater treatment, comprising the following steps:

[0037] (1) the chromium mud that 500g extracts vanadium waste water water treatment precipitation is placed in muffle furnace high-temperature roasting, during roasting, sodium salt and vanadium remaining in the chromium mud of vanadium extracting waste water take place sodiumization roasting reaction again, obtain 110g Roasted product, wherein, Cr in the roasted product 2 o 3 Content 63.1wt.%; Among them, the high-temperature calcination temperature is 800 ℃, and the high-temperature calcination time is 2 hours;

[0038] (2) The roasted product is placed in a beaker, water is added, stirred and washed at 80° C., solid-liquid separation is obtained to obtain the washing liquid and the roasted product after washing, and the mass concentration of vanadium in the washing liquid is C V =1.66g / L, reuse after treatment, the roasted p...

Embodiment 3

[0042] A method for resource utilization of chrome sludge precipitated by vanadium extraction wastewater treatment, comprising the following steps:

[0043] (1) The chrome mud that 1000g extracts vanadium waste water treatment precipitation is placed in muffle furnace high-temperature roasting, during roasting, sodium salt and vanadium remaining in the chrome mud of vanadium extracting waste water take place sodium roasting reaction again, obtain 230g Roasted product, wherein, Cr in the roasted product 2 o 3 Content 62.5wt.%; Among them, the high-temperature calcination temperature is 1000 ℃, and the high-temperature calcination time is 0.5h;

[0044](2) The roasted product is placed in a beaker, water is added, stirred and washed at 100° C., solid-liquid separation is obtained to obtain the washing liquid and the roasted product after washing, and the mass concentration of vanadium in the washing liquid is C V =1.63g / L, return to the vanadium precipitation process after tre...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com