Flowing current separation process coal mine underground gangue dumping system

An underground gangue discharge and channel selection technology, which is applied in the direction of solid separation, wet separation, chemical instruments and methods, etc., can solve the problem of multiple supporting equipment for the jig discharge system, complex process and low cost of the dense medium shallow tank discharge system. Problems such as the actual production capacity of mines, to achieve the effects of increasing production capacity and economic benefits, reducing kinetic energy consumption and transportation costs, and avoiding environmental disasters

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

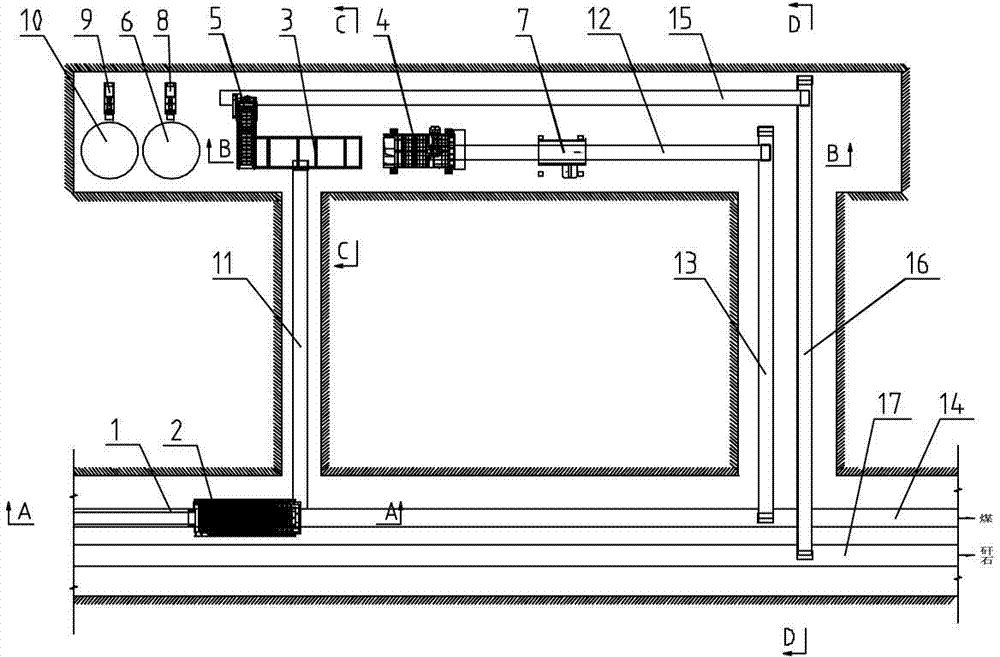

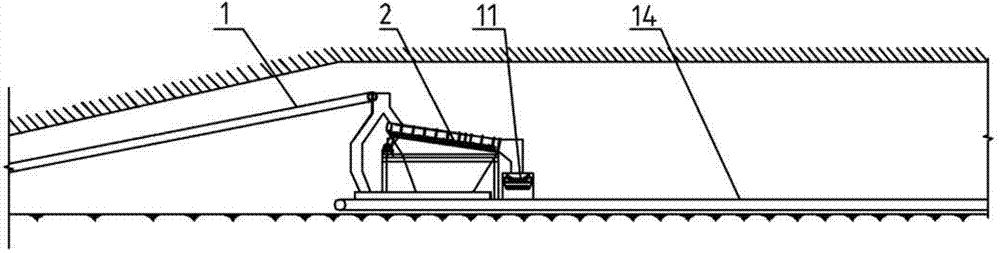

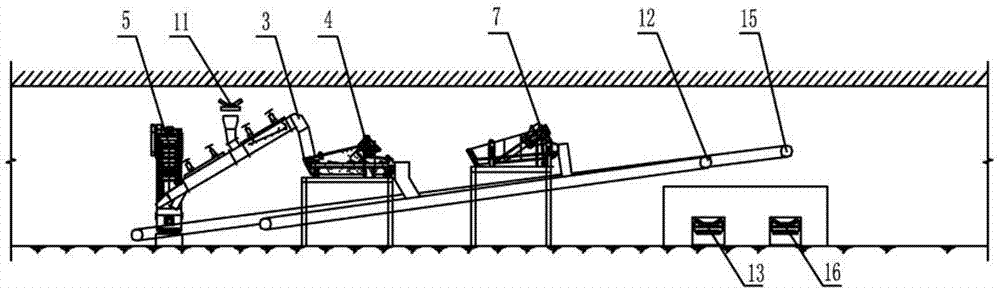

[0023] Such as Figure 1-6 As shown, an underground gangue discharge system of channel separation process coal mine, including raw coal conveyor (1), roller screen (2), channel separator (3), dewatering screen (4), bucket elevator (5) , concentration pool (6), high-frequency screen (7), concentration underflow pump (8), circulating water pump (9), circulating water pool (10), raw coal conveyor for selection on the screen (11), lump coal conveyor (12 ), lump coal reloading conveyor (13), powder coal conveyor (14), gangue conveyor (15), gangue reloading conveyor (16) and gangue warehousing conveyor (17).

[0024] The raw coal conveyor (1) is installed on the side of the feed end of the roller screen (2). The material inlet (3-1) in the middle section of the separator (3), the amount of material fed into the slot separator (3) is controlled by the gate of the discharge outlet, and the lump coal outlet (3-2) of the slot separator (3) ) is connected with the dewatering screen (4)...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com