Flexible assembling tooling

A flexible assembly and tooling technology, applied in aircraft assembly, ground equipment, manufacturing tools, etc., can solve problems such as restricting the development of the aircraft manufacturing industry, prolonging the aircraft assembly and manufacturing cycle, and occupying a large area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

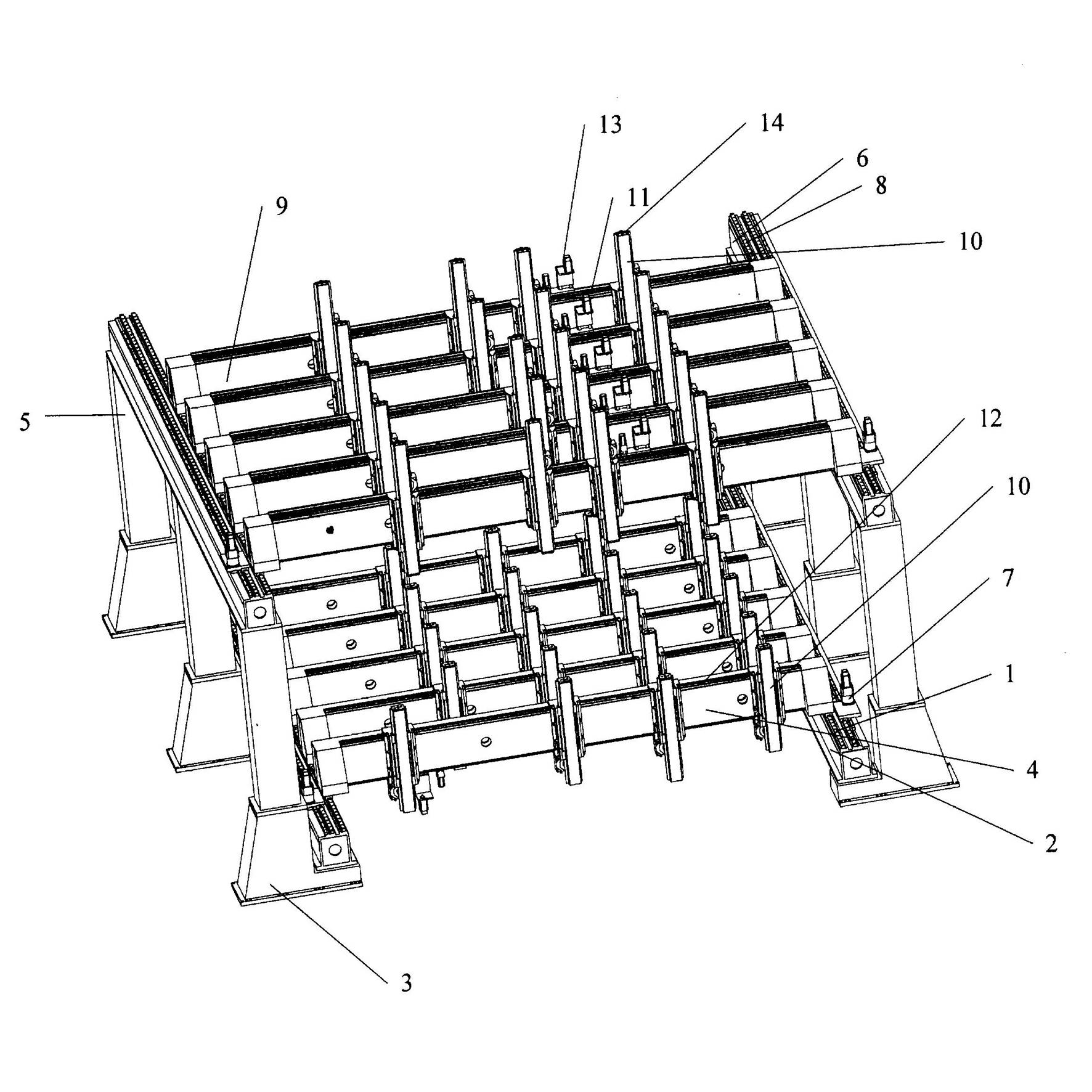

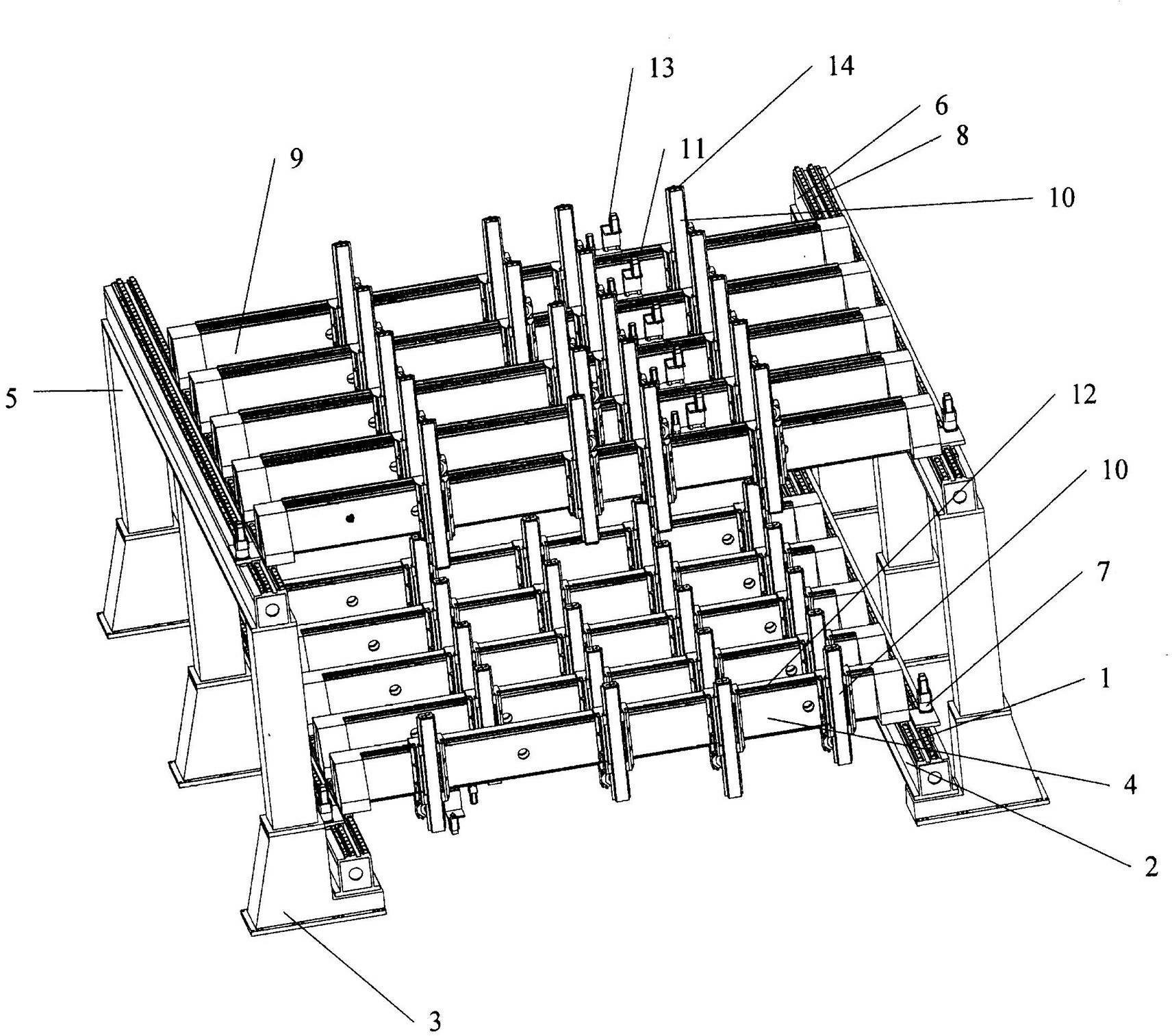

[0009] Such as figure 1 As shown, a flexible assembly tool, six skeleton bases 3 are divided into two groups, and the two components are arranged in parallel, and a skeleton column 5 is arranged on the upper part of each skeleton base 3, and each row of skeleton columns 5 is respectively connected to a longitudinal skeleton beam 6 , the upper surface of the skeleton beam 6 is provided with a longitudinal linear guide rail I8, five parallel and horizontally arranged upper moving beams 9 are arranged between the two longitudinal linear guide rails I8, and a horizontal linear guide rail I11 is arranged on the upper moving beam 9; The inner side of each group of skeleton bases 3 is provided with a support frame 2, and the upper end of the support frame 2 is provided with a longitudinal linear guide rail II1, and five parallel and horizontally arranged lower moving beams 4 are arranged between the two longitudinal linear guide rails II1; A horizontal linear guide rail II12 is provi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com