Method for coproduction of bleaching powder, active carbon, sodium chloride and sulphuric acid from waste gypsum plaster

A technology of bleaching powder and waste gypsum, which is applied in the direction of sulfur trioxide/sulfuric acid, hypochlorous acid, hypochlorite, etc., and can solve problems such as land occupation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

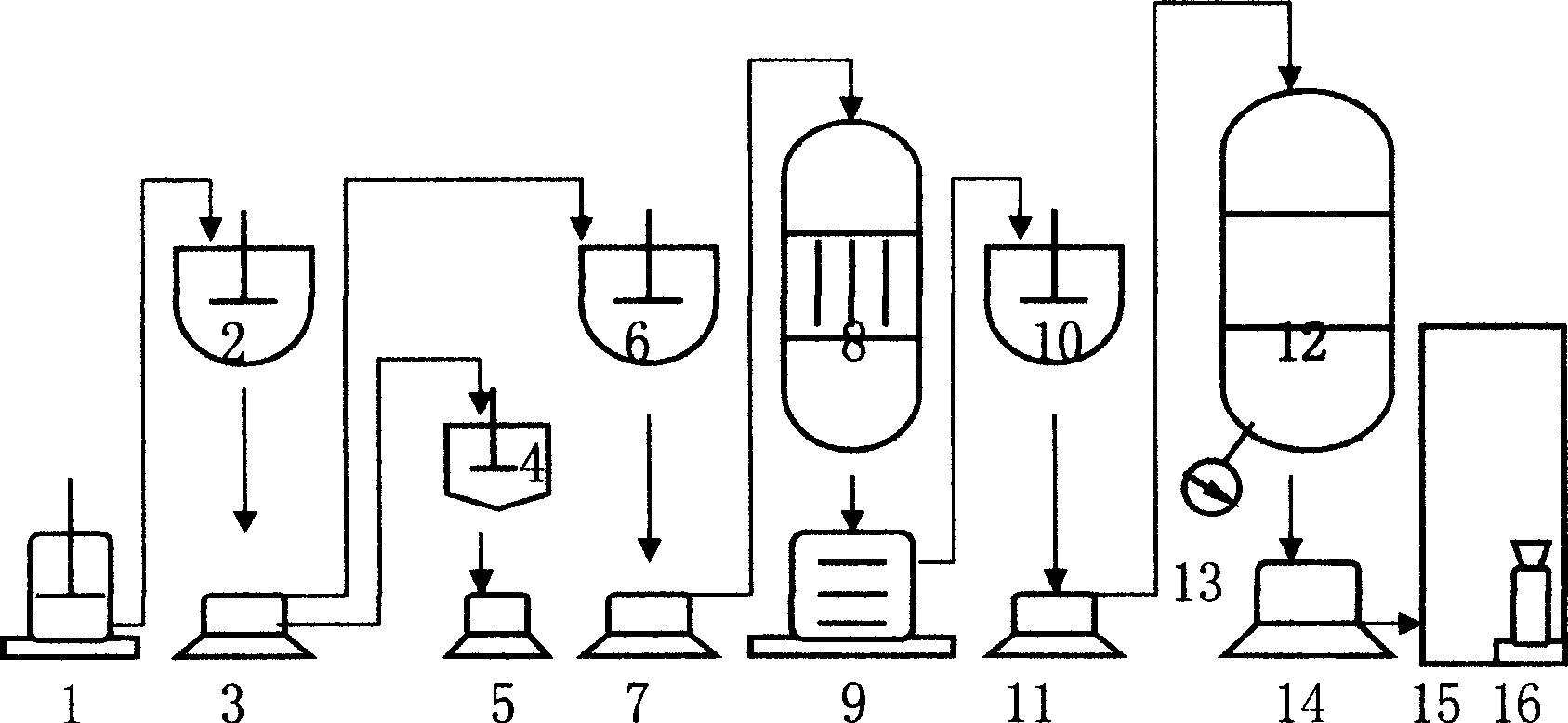

Method used

Image

Examples

Embodiment 1

[0019] Example 1: Take 400kg of waste gypsum mud from a titanium dioxide factory and inject industrial water into the preprocessor (1) at a weight ratio of 1:6, stir to form an emulsion and naturally settle to remove impurities at the bottom to obtain a relatively pure gypsum emulsion. Then inject the clarifier (2) with hydrochloric acid in a mass ratio of 1:0.4 and carry out the stirring reaction to obtain a mixed solution of calcium chloride and sulfuric acid, and centrifuge (3) to obtain a filter cake that can refine 24kg of activated carbon, and obtain the filtrate respectively. Calcium chloride 192.62 kg and sulfuric acid 171.82kg; Filtrate and sodium sulfate are mixed in side reactor (6) by mass ratio 1:1.2 and react to generate pure calcium sulfate 223.68kg and sodium chloride 192.42kg, get filtrate through distillation ( 8) sodium chloride crystals (9) and concentrated sulfuric acid; the remaining filter cake continues to react with sodium hydroxide in the main reactor ...

Embodiment 2

[0020] Example 2: Take 400kg of waste gypsum mud and water into the preprocessor at a ratio of 1:4 and stir to form a uniform emulsion. After standing still, the relatively pure emulsion and hydrochloric acid are injected into a purifier at a ratio of 1:0.2 to generate chloride A mixture of calcium 97.32kg and sulfuric acid 85.92kg. The filtered filter cake can be used as 24kg of activated carbon; the filtrate is reacted with sodium sulfate at a ratio of 1:1 to obtain precipitated calcium sulfate 119.24kg and sodium chloride 102.58kg, and the filtered filtrate is distilled to obtain chlorine Sodium chloride and sulfuric acid; filter cake and sodium hydroxide are reacted by 1:0.2 to obtain calcium hydroxide 22.06kg and sodium sulfate 42.32kg, through filtering sodium sulfate; filter cake and chlorine are sent into chlorination tower and chlorinated by 1:0.4 respectively to obtain 12.7kg of bleaching powder and 6.9kg of calcium chloride were separated to obtain a calcium chloride...

Embodiment 3

[0021] Example 3: Take 400kg of waste gypsum mud and water and inject it into the preprocessor at a ratio of 1:8 and stir it into a uniform emulsion. The mixed solution of calcium 261.18kg and sulfuric acid 230.58kg, the filtered filter cake can be used as activated carbon 24kg; the filtrate is reacted with sodium sulfate at a ratio of 1:1.4 to obtain precipitated calcium sulfate 320kg and sodium chloride 275.3kg, and the filtered filtrate is distilled to obtain chloride Sodium and sulfuric acid; filter cake and sodium hydroxide are reacted by 1:0.7 to obtain calcium hydroxide 175.2kg and sodium sulfate 334.4kg, after filtering sodium sulfate; filter cake and chlorine are sent into chlorination tower respectively by 1:1.1 to obtain bleaching 180.28 kg of fine powder and 97.94 kg of calcium chloride were separated to obtain a calcium chloride solution. The bleaching powder was dried, pulverized, and packaged to become a standard product.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com