Method of producing calcium fluoride through bottom mud generated by fluoride waste

A calcium fluoride and sediment technology, applied in the direction of calcium/strontium/barium fluoride, calcium/strontium/barium halide, etc., can solve the problems of waste of fluorine resources, no utilization method, and calcium hydroxide cannot be fully utilized. , to achieve the effect of less pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

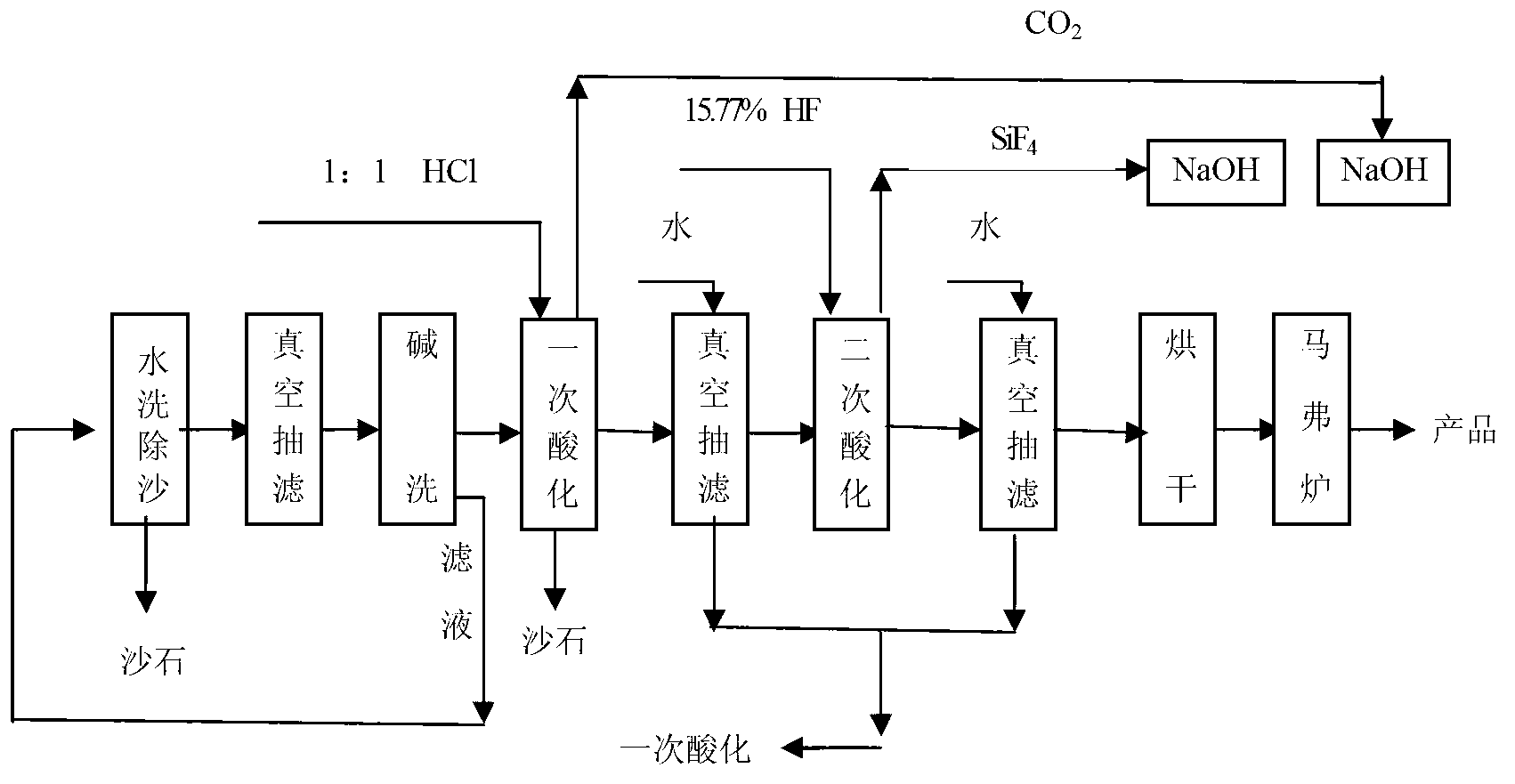

Method used

Image

Examples

Embodiment Construction

[0024] The invention is illustrated by the following examples.

[0025] The sediment discharged from an enterprise producing aluminum fluoride and hydrofluoric acid in Ningxia was used as the experimental raw material, and its chemical composition analysis is shown in Table 2.

[0026] Table 2 Raw material (bottom mud) composition list

[0027]

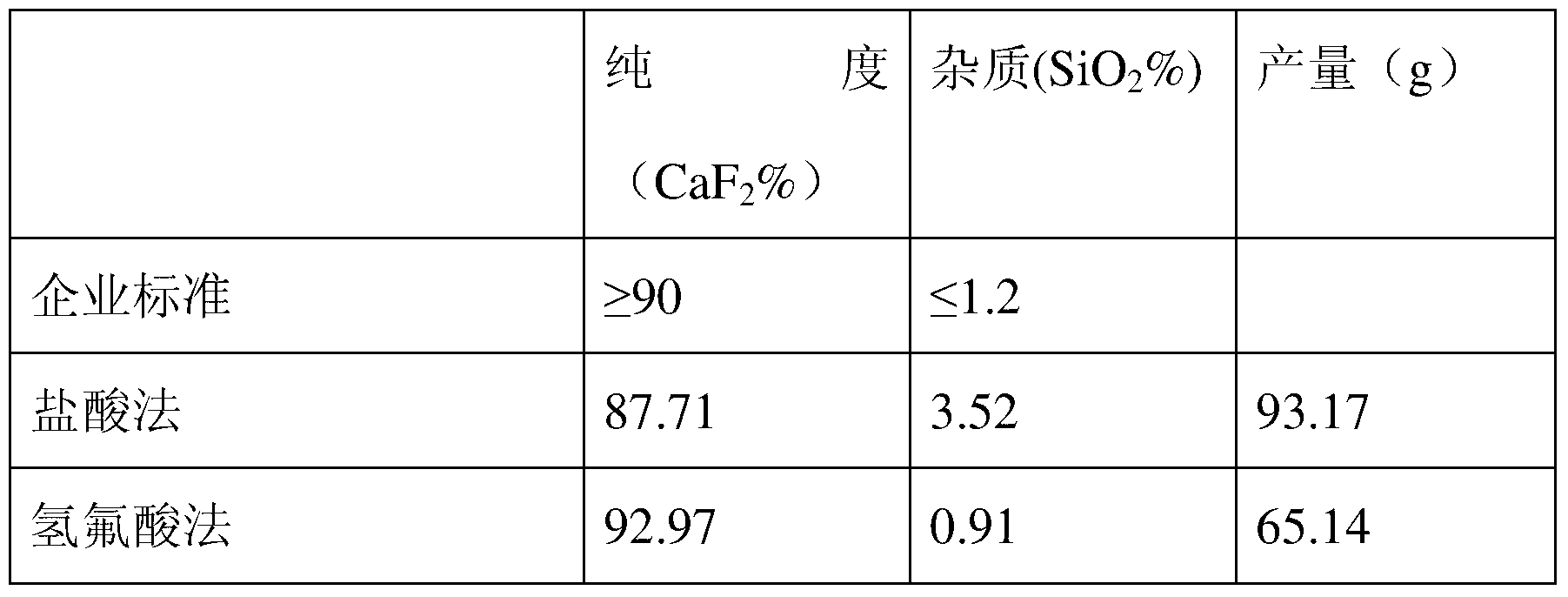

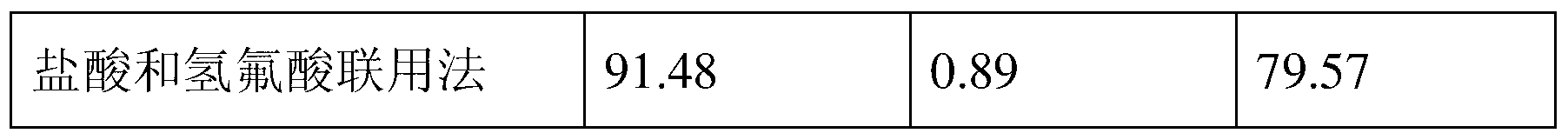

[0028] Three methods are used to deal with it:

[0029] (1) hydrochloric acid method

[0030] principle

[0031] Use sodium carbonate to react with calcium sulfate to generate calcium carbonate and water-soluble sodium sulfate to remove calcium sulfate; use hydrochloric acid to react with calcium carbonate and calcium hydroxide to generate water-soluble calcium chloride and carbon dioxide to remove calcium carbonate and calcium hydroxide can be removed; the sand is removed by using the characteristics of large specific gravity and fast sedimentation speed; the coal gangue powder is burned by high temperature. The reaction equat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com