Silicon-aluminum base marine concrete material and preparing method thereof

A marine concrete and silica-alumina-based technology, applied in cement production, etc., can solve problems such as inconvenient transportation, large resource consumption, energy, pollution, etc., achieve durability and seawater erosion resistance, reduce construction costs, and reduce production cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0034] A method for preparing silicon-aluminum-based marine concrete material includes the following steps:

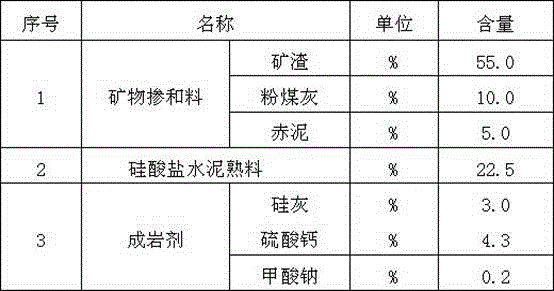

[0035] (1) Mix the slag, fly ash, red mud, Portland cement clinker, silica fume, calcium sulfate and sodium formate according to the weight ratio in Table 1 below, and add the materials in the ratio to the ball mill for mixing Grind for 30 minutes to prepare CaO / (SiO 2 +Al 2 O 3 )=0.96, the specific surface area is 502cm 2 / kg.

[0036] Table 1

[0037]

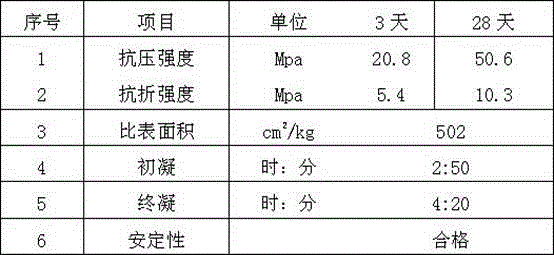

[0038] The physical properties of the silica-aluminum-based cementitious materials prepared in Table 1 above are shown in Table 2 below:

[0039] Table 2

[0040]

[0041] (2) The silica-alumina-based cementing material prepared in the above step (1), river sand, stone, and polycarboxylic acid early-strength water reducing agent are weighed at a weight ratio of 1:2:4:0.015 for use.

[0042] (3) Measure the amount of water according to the water-cement ratio (that is, the ratio of water to the material obtained in step (2)) of 0...

Embodiment 2

[0048] A method for preparing silicon-aluminum-based marine concrete material includes the following steps:

[0049] (1) Mix slag, pozzolan, steel slag, Portland cement clinker, fluorspar, calcium sulfate and calcium carbonate according to the weight ratio in Table 4 below, and add the materials in the ratio to the ball mill for mixing and grinding 30 Minutes to prepare CaO / (SiO 2 +Al 2 O 3 )=1.03, the specific surface area is 486cm 2 / kg.

[0050] Table 4

[0051]

[0052] The physical properties of the silica-alumina-based cementitious materials prepared in Table 4 above are shown in Table 5 below:

[0053] table 5

[0054]

[0055] (2) The silica-alumina-based cementing material prepared in the above step (1), sea sand, stone, and polycarboxylic acid early-strength water reducing agent are weighed according to the weight ratio of 1:1.5:4:0.015 for use.

[0056] (3) Measure the amount of water according to the water-cement ratio (that is, the ratio of water to the material obtained in...

Embodiment 3

[0062] A method for preparing silicon-aluminum-based marine concrete material includes the following steps:

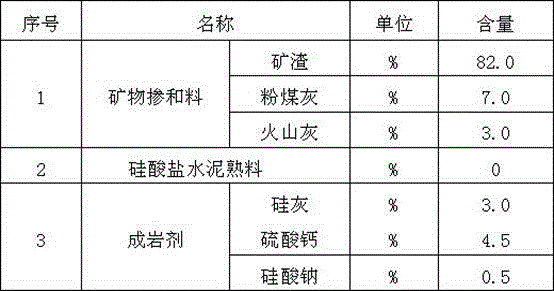

[0063] (1) Mix slag, fly ash, pozzolan, silica fume, calcium sulfate, and sodium silicate according to the weight ratio in Table 7 below. Add the materials in the ratio to a ball mill for mixing and grinding for 30 minutes to prepare silicon Aluminum-based cementitious material CaO / (SiO 2 +Al 2 O 3 )=0.78, the specific surface area is 466cm 2 / kg.

[0064] Table 7

[0065]

[0066] (2) The silica-alumina-based cementing material prepared in the above step (1), coral sand, stones, and active agent are weighed at a weight ratio of 1:2:2:0.03 for use.

[0067] (3) Measure the amount of water according to the water-cement ratio (that is, the ratio of water to the material obtained in step (2)) of 0.58, add water to the mixer, and then add the materials prepared in step (2) to the mixer one by one, and add the materials while stirring .

[0068] (4) Stir for 3 minutes to make a sil...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Compressive strength | aaaaa | aaaaa |

| Flexural strength | aaaaa | aaaaa |

| Permeability | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com