Tailing carbonization cemented filling method

A technology of cemented filling and tailings, applied in the field of tailings filling, can solve the problems of high cost of cementitious materials, high cost of mineralization storage technology, low utilization rate of high calcium and magnesium solid waste, etc., and achieve low cost and high filling strength Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

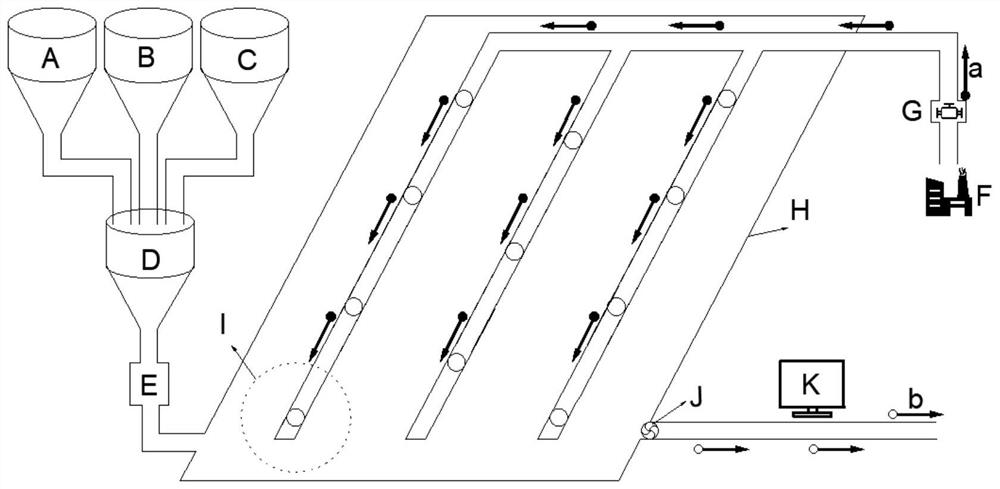

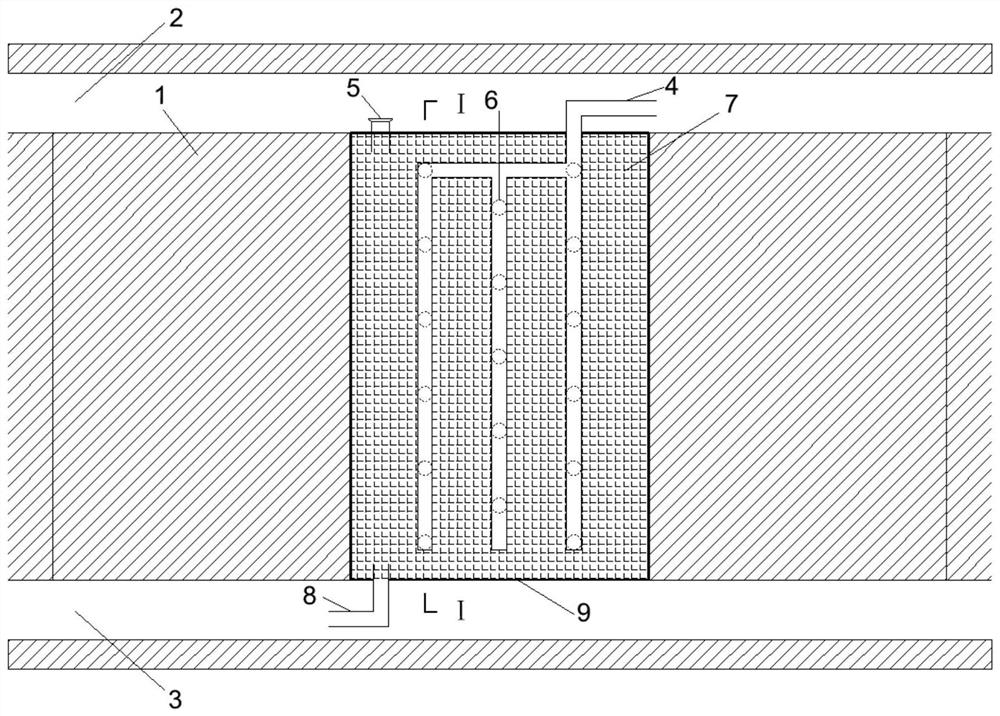

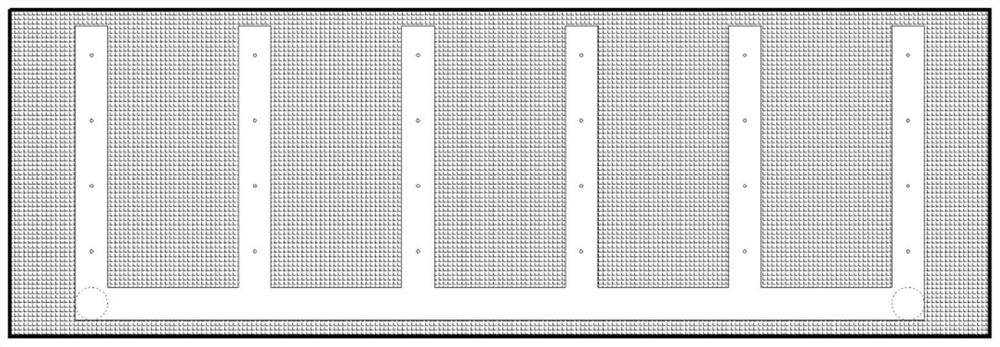

[0035] In order to make the technical problems, technical solutions and advantages to be solved by the present invention clearer, the following will describe in detail with reference to the drawings and specific embodiments.

[0036] The invention provides a tailing sand carbonization cementation filling method.

[0037] The method includes steps as follows:

[0038] S1: crush and grind the cementitious material, and use whole tailings as the aggregate;

[0039] S2: Fully stir the cementitious material, whole tailings, water and additives in S1 to prepare filling slurry;

[0040] S3: Arrange CO in the goaf 2 gas pipeline;

[0041] S4: Transport the filling slurry prepared in S2 to the filling station, and transport it to the underground goaf by means of pipeline pumping;

[0042] S5: After the goaf is filled, the filling area is closed and blocked to ensure the gas tightness of the filling area;

[0043] S6: After 24 hours of closing the filling area, through the CO arrange...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com