Method for treating vanadium industrial wastewater through magnesium-process desulfurization waste

A technology of magnesium-based desulfurization and industrial wastewater, applied in chemical instruments and methods, water pollutants, multi-stage treatment of water/sewage, etc., can solve the problem of reducing the pyrolysis temperature of desulfurization products, poor quality of magnesium sulfate, and increasing oxidation equipment, etc. To achieve the effect of realizing resource utilization, solving pollution and land occupation problems, and reducing treatment costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

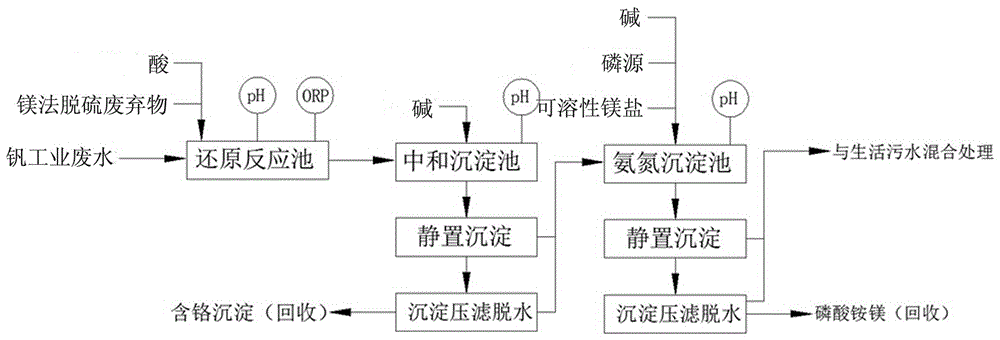

[0027] The method that the magnesium method desulfurization waste of present embodiment treats vanadium industrial waste water, as figure 1 shown, follow the steps below:

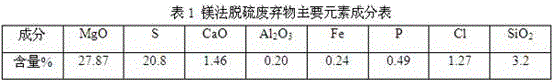

[0028] (1) Introduce the vanadium industrial wastewater from a factory in Hebei into the reduction reaction tank, stir and add the magnesium desulfurization waste, the amount of the magnesium desulfurization waste added is Cr in the vanadium industrial wastewater 6+ and V 5+ 10 times the total mass, adjust pH=2.0 with sulfuric acid, control ORP270mv, react for 20min, during the reaction process, the high-valence vanadium and chromium in the wastewater are reduced to low-valence states;

[0029] (2) Introduce the reduced waste water into the neutralization sedimentation tank, continue to stir the reduced waste water and adjust the pH=7.0 with sodium hydroxide, react for 10 minutes, add the flocculant polyacrylamide, the amount of flocculant added is 10ppm, and a large amount of alum is formed Flower flocs,...

Embodiment 2

[0033] (1) Introduce the vanadium industrial wastewater from a factory in Heilongjiang into the reduction reaction tank, stir and add the magnesium desulfurization waste, the amount of the magnesium desulfurization waste added is Cr in the vanadium industrial wastewater 6+ and V 5+7 times the total mass, adjust pH=3.0 with hydrochloric acid, control ORP300mv, react for 30min, during the reaction process, the high-valence vanadium and chromium in the wastewater are reduced to low-valence states;

[0034] (2) Introduce the reduced waste water into the neutralization sedimentation tank, continue to stir the reduced waste water and adjust the pH=6.5 with sodium hydroxide, react for 30 minutes, add flocculant polyaluminium chloride, the amount of flocculant added is 50ppm, forming a large amount of Alum flower flocs, continue to stir for 10min, let stand to settle for 3h, and the precipitate obtained is dehydrated by pressure filtration to form a primary chromium hydroxide precipit...

Embodiment 3

[0038] (1) Introduce the vanadium industrial wastewater from a factory in Heilongjiang into the reduction reaction tank, stir and add the magnesium desulfurization waste, the amount of the magnesium desulfurization waste added is Cr in the vanadium industrial wastewater 6+ and V 5+ 5 times the total mass, adjust pH=1.0 with nitric acid, control ORP≥320mv, and react for 10 minutes. During the reaction, the high-valence vanadium and chromium in the wastewater are reduced to low-valence states;

[0039] (2) Introduce the reduced waste water into the neutralization sedimentation tank, continue to stir the reduced waste water and adjust the pH=9.0 with sodium hydroxide, react for 20 minutes, add flocculant polymerized ferric sulfate, the amount of flocculant added is 100ppm, and a large amount of alum is formed For flocs, continue to stir for 5 minutes, and let it settle for 0.5 hours. The obtained precipitate is dehydrated by pressure filtration to form a primary chromium hydroxid...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com