Slag-free production process using bauxite or red mud

A process method and bauxite technology, applied in the field of metal smelting, can solve problems such as no benefit, blast furnace slag spewing, waste of resources, etc., and achieve the effects of reducing production costs, low operating costs, and high economic benefits

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

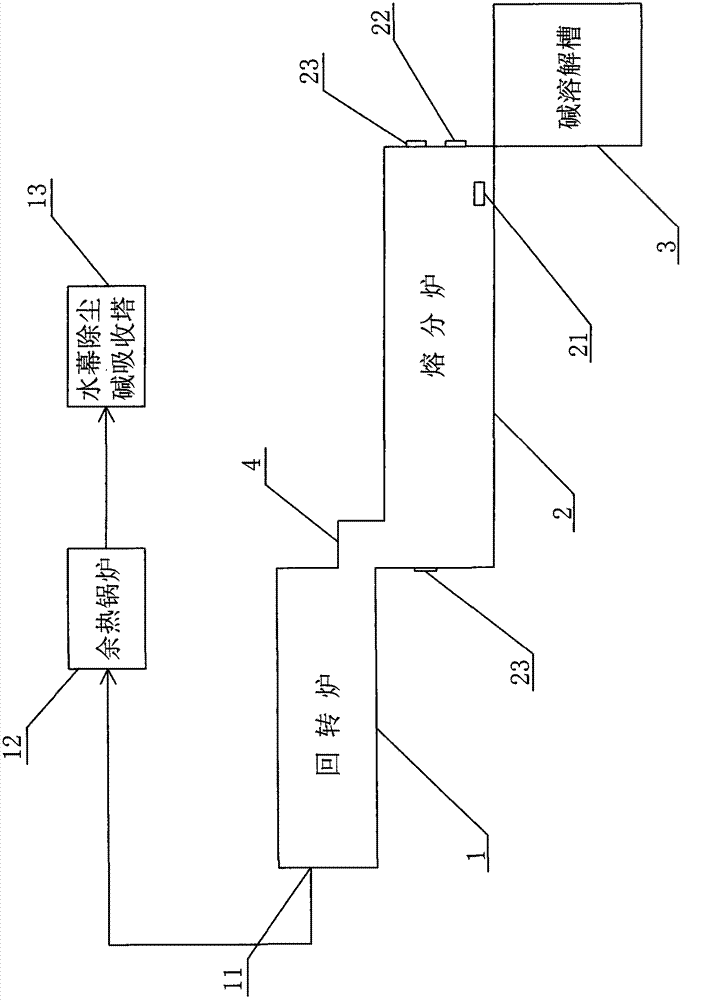

[0034] see figure 1 , a process for utilizing bauxite or red mud to produce slag-free production, comprising the steps of:

[0035] a) Take bauxite or red mud, lime, and coal according to the percentage by weight of 1:0.05:0.2, and mix them uniformly to make mixed raw meal;

[0036] b) Add the above mixed raw material into the rotary kiln 1, the temperature in the rotary kiln 1 from the tail to the head gradually rises from 800 degrees Celsius to 1460 degrees Celsius; after 2 hours of drying and pre-reduction, the semi-molten state of reducing material;

[0037] c) The above-mentioned reducing material is entered into the melting furnace 2 through the closed passage 4 through the discharge port of the rotary kiln 1; three gas guns 23 are installed at the head of the melting furnace 2, and the guns of the gas guns 23 are The mouths are all facing the tail of the melting furnace 2, and the reducing materials are heated and melted; three gas guns 23 are installed at the tail of...

Embodiment 2

[0041] see figure 1 , a process for utilizing bauxite or red mud to produce slag-free production, comprising the steps of:

[0042] a) Take bauxite or red mud, lime, and coal according to the percentage by weight of 1:0.1:0.3, and mix them uniformly to make mixed raw meal;

[0043] b) Add the above mixed raw meal into the rotary kiln 1, the temperature in the rotary kiln 1 from the tail to the head gradually rises from 800 degrees Celsius to 1460 degrees Celsius; after 5 hours of drying and pre-reduction, the semi-molten state of reducing material;

[0044] c) The above-mentioned reducing material is entered into the melting furnace 2 through the closed passage 4 through the discharge port of the rotary kiln 1; three gas guns 23 are installed at the head of the melting furnace 2, and the guns of the gas guns 23 are The mouths are all facing the tail of the melting furnace 2, and the reducing materials are heated and melted; three gas guns 23 are installed at the tail of the ...

Embodiment 3

[0048] see figure 1 , a process for utilizing bauxite or red mud to produce slag-free production, comprising the steps of:

[0049] a) Take bauxite or red mud, lime, and coal according to the percentage by weight of 1:0.2:0.4, and mix them uniformly to make mixed raw meal;

[0050] b) Add the above mixed raw material into the rotary kiln 1, the temperature in the rotary kiln 1 from the tail to the head gradually rises from 800 degrees Celsius to 1460 degrees Celsius; after 7 hours of drying and pre-reduction, the semi-molten state of reducing material;

[0051] c) The above-mentioned reducing material is entered into the melting furnace 2 through the closed passage 4 through the discharge port of the rotary kiln 1; three gas guns 23 are installed at the head of the melting furnace 2, and the guns of the gas guns 23 are The mouths are all facing the tail of the melting furnace 2, and the reducing materials are heated and melted; three gas guns 23 are installed at the tail of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com