Method for producing ferrosilicon alloy by means of metallurgical silicon slag

A technology of ferrosilicon alloy and metallurgical silicon, which is applied in the field of ferrosilicon alloy production, can solve the problems of waste of resources, high labor intensity, discarding of ferrosilicon, etc., and achieve the effect of solving pollution problems, realizing energy saving and consumption reduction, and realizing reuse

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

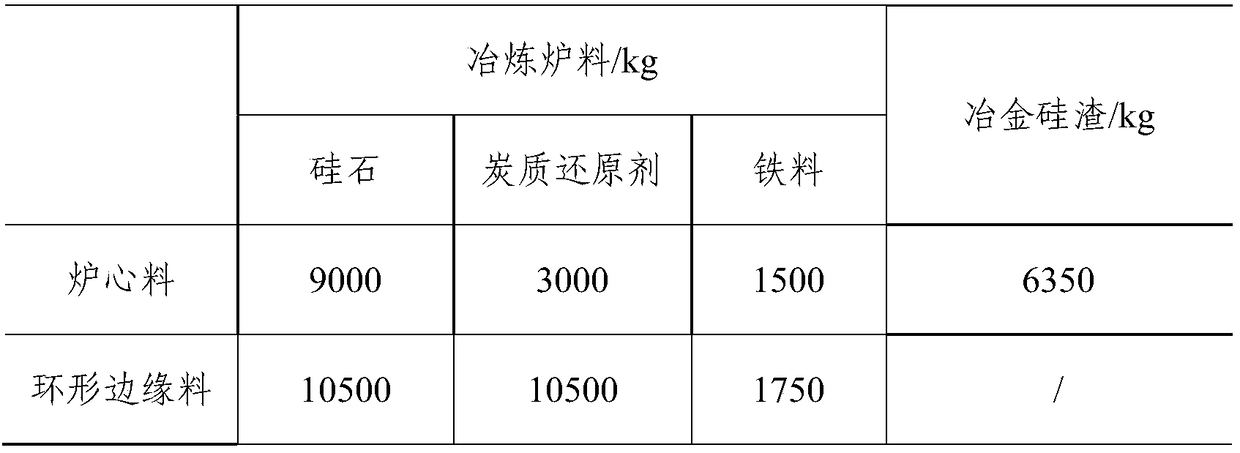

[0032] The embodiment of the present invention provides a method for producing ferrosilicon alloy by using metallurgical silicon slag. The smelting area in the submerged arc furnace is divided into a furnace core area and an annular edge area, and the ingredients are fed into the furnace as shown in Table 1 below.

[0033] Table 1 Consumption comparison table (kg) of the smelting raw materials adopted in the embodiment of the present invention 1

[0034]

[0035] Among them, the detection results of each element of metallurgical silicon slag are shown in Table 2 below.

[0036] Table 2 The detection result table of each element of the metallurgical silicon slag adopted in the embodiment 1 of the present invention

[0037]

[0038] The smelting process is as follows:

[0039] (1) Furnace smelting: according to the above-mentioned ratio, the core material and the ring edge material are respectively weighed, placed in the submerged arc furnace, and the smelting operation i...

Embodiment 2

[0046] The embodiment of the present invention provides a method for producing ferrosilicon alloy using metallurgical silicon slag. The smelting area in the submerged arc furnace is divided into a furnace core area and an annular edge area, and the ingredients are fed into the furnace as shown in Table 3 below.

[0047] Table 3 Consumption comparison table (kg) of the smelting raw materials adopted in the embodiment of the present invention 2

[0048]

[0049] Wherein, the detection results of each element of the metallurgical silicon slag are the same as those in Example 1.

[0050] In addition, its smelting process is similar to that of Example 1, and will not be repeated here.

[0051]Using the above conditions, the production indicators of ferrosilicon alloy can reach: power consumption is 7880 kWh / ton, comprehensive cost is 5500 yuan / ton, single furnace output is 42.5 tons / day, and the qualified rate of products is 98.5%.

Embodiment 3

[0053] The embodiment of the present invention provides a method for producing ferrosilicon alloy using metallurgical silicon slag. The smelting area in the submerged arc furnace is divided into a furnace core area and an annular edge area, and the ingredients are fed into the furnace as shown in Table 4 below.

[0054] Table 4 Consumption comparison table (kg) of the smelting raw materials adopted in the embodiment of the present invention 3

[0055]

[0056] Wherein, the detection results of each element of the metallurgical silicon slag are the same as those in Example 1.

[0057] In addition, its smelting process is similar to that of Example 1, and will not be repeated here.

[0058] Using the above conditions, the production indicators of ferrosilicon alloy can reach: power consumption is 7950 kWh / ton, comprehensive cost is 5680 yuan / ton, single furnace output is 41.0 tons / day, and the product qualification rate is 96.5%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com