Self-adaptive flexible supporting and positioning mechanism

A positioning mechanism and flexible positioning technology, applied in aircraft assembly, aircraft parts, ground installations, etc., can solve the problems of prolonging the aircraft assembly and manufacturing cycle, large tooling storage area, and restricting the development of the aircraft manufacturing industry, so as to save manufacturing costs , solve the problem of tooling occupying land, and ensure the effect of quality requirements

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

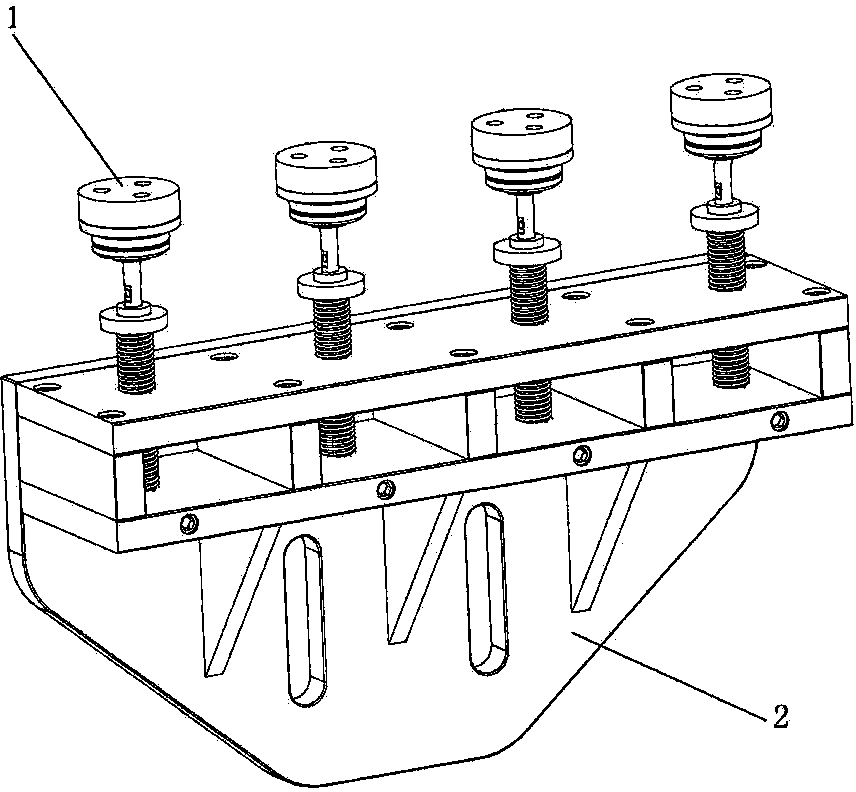

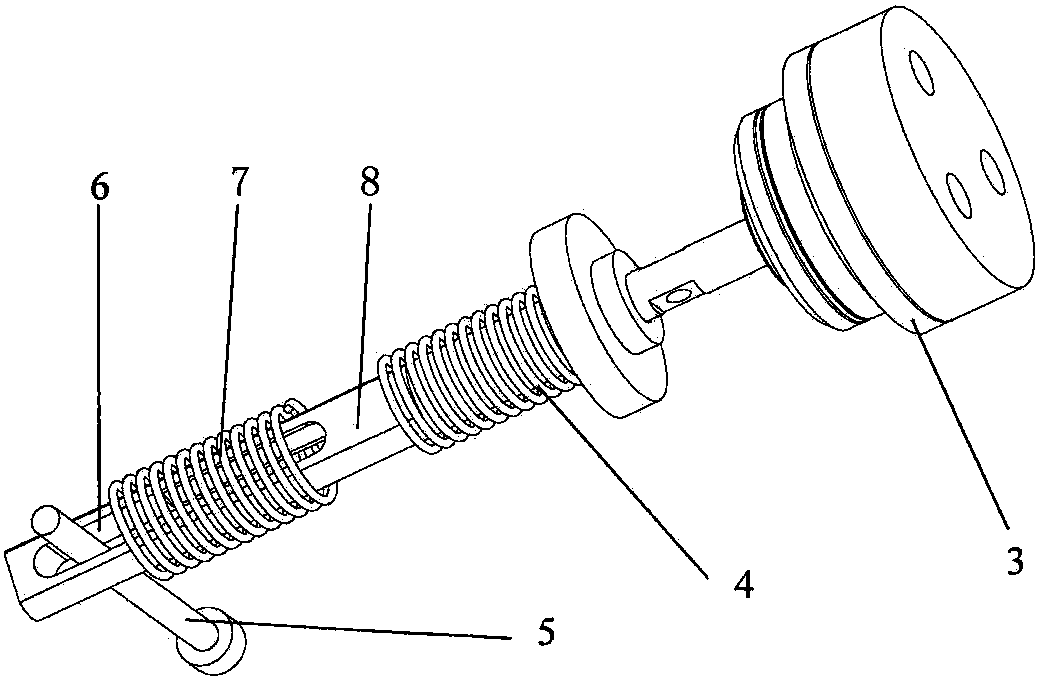

[0021] Such as Figure 1-5 As shown, the adaptive flexible positioning mechanism includes an adaptive flexible positioning unit 1 and a supporting frame assembly 2. The adaptive flexible positioning unit 1 supports and positions through the supporting frame assembly 2, and supports positioning and self-supporting through the supporting frame assembly 2. Adapting to the adjustment of the flexible positioning unit 1, including the swing adjustment of the flexible positioning component and the straight line adjustment of the main connecting rod 8, it is possible to realize the support positioning of the plane or any angle curved surface. The waist-shaped positioning hole 9 is connected with any drilling and riveting tooling equipment.

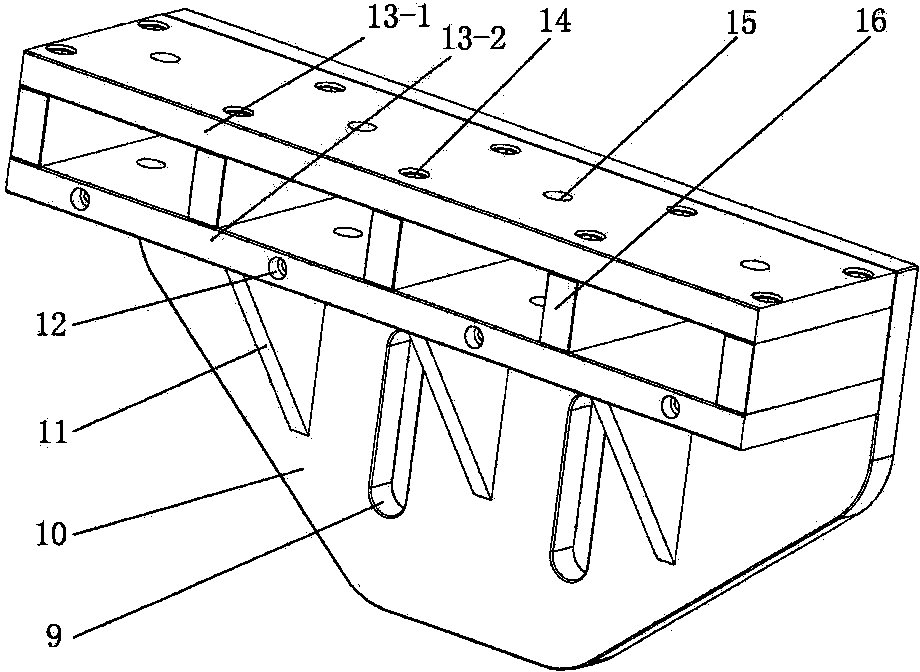

[0022] The structure of the support frame assembly 2 is: the top of the support main board 10 is connected with the upper positioning plate 13-1 and the lower positioning plate 13-2 respectively, and the waist-shaped positioning hole 9 is provided...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com