Full recovery method of waste lithium ion battery electrolyte

A lithium-ion battery and electrolyte technology, applied in the field of lithium-ion batteries, can solve problems such as demolition, high enrichment process requirements, unstable lithium hexafluorophosphate, and increased process costs, and achieve environmental protection, high feasibility, and resource conservation. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

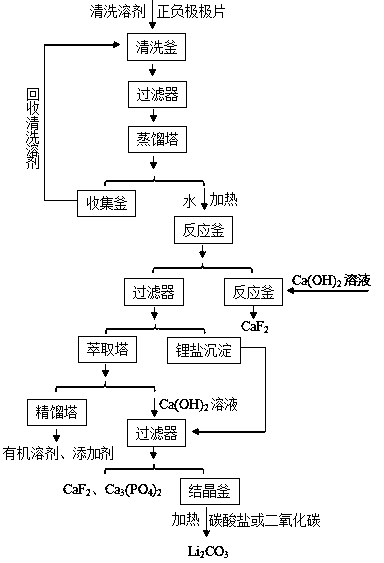

Method used

Image

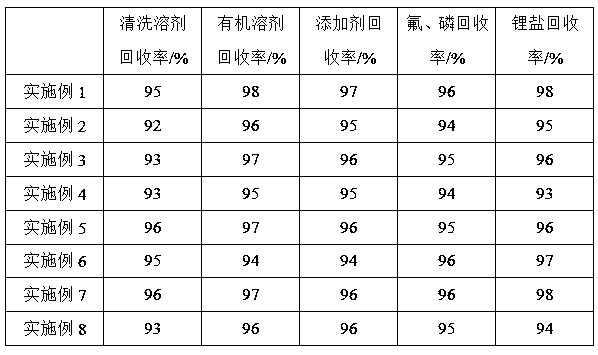

Examples

Embodiment 1

[0023] A method for fully recovering waste lithium-ion battery electrolyte, the steps are as follows:

[0024] (1) Cleaning process

[0025] Soak the waste lithium ion battery containing waste electrolyte with dimethyl carbonate solvent, and extract the electrolyte after ultrasonic, stirring and filtering;

[0026] (2) Cleaning solvent recovery process

[0027] Control the vacuum to be 100mbar and the temperature to be 30°C for vacuum distillation, recover the dimethyl carbonate solvent used in step (1), and collect the electrolyte;

[0028] (3) Recovery process of organic solvents and additives

[0029] Add water to the collected electrolyte in step (2), heat at 30°C, filter to obtain lithium salt precipitation and filtrate, pass the filtrate into the extraction tower, and purify and separate the organic phase one by one through the rectification tower. The number of plates in the rectification tower is 40 blocks, reaction temperature is 150℃, operating pressure is 20KPa, reflux ratio ...

Embodiment 2

[0035] A method for fully recovering waste lithium-ion battery electrolyte, the steps are as follows:

[0036] (1) Cleaning process

[0037] Soak the waste lithium ion battery containing waste electrolyte with ethyl methyl carbonate solvent, and extract the electrolyte after ultrasonic, stirring and filtering;

[0038] (2) Cleaning solvent recovery process

[0039] Control the vacuum to 500mbar and the temperature to 100°C to perform vacuum distillation, recover the ethyl methyl carbonate solvent used in step (1), and collect the electrolyte;

[0040] (3) Recovery process of organic solvents and additives

[0041] Add water to the collected electrolyte in step (2), heat at 100°C, and filter to obtain lithium salt precipitation and filtrate. The filtrate is passed into the extraction tower, and the organic phase is purified and separated one by one through the rectification tower. The number of plates in the rectification tower is 80 Block, reaction temperature is 250°C, operating pressu...

Embodiment 3

[0047] A method for fully recovering waste lithium-ion battery electrolyte, the steps are as follows:

[0048] (1) Cleaning process

[0049] Soak the waste lithium ion battery containing waste electrolyte with diethyl carbonate solvent, and extract the electrolyte after ultrasonic, stirring and filtering;

[0050] (2) Cleaning solvent recovery process

[0051] Control the vacuum to 200mbar and the temperature to 50°C to perform vacuum distillation, recover the diethyl carbonate solvent used in step (1), and collect the electrolyte;

[0052] (3) Recovery process of organic solvents and additives

[0053] Add water to the collected electrolyte in step (2), heat at 50°C, and filter to obtain lithium salt precipitation and filtrate. The filtrate is passed into the extraction tower, and the organic phase is purified and separated one by one through the rectification tower. The number of plates in the rectification tower is 5 Block, the reaction temperature is 50°C, the operating pressure is ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com