Process for preparing high-purity artificial fluorite by recovering fluoride-containing wastewater

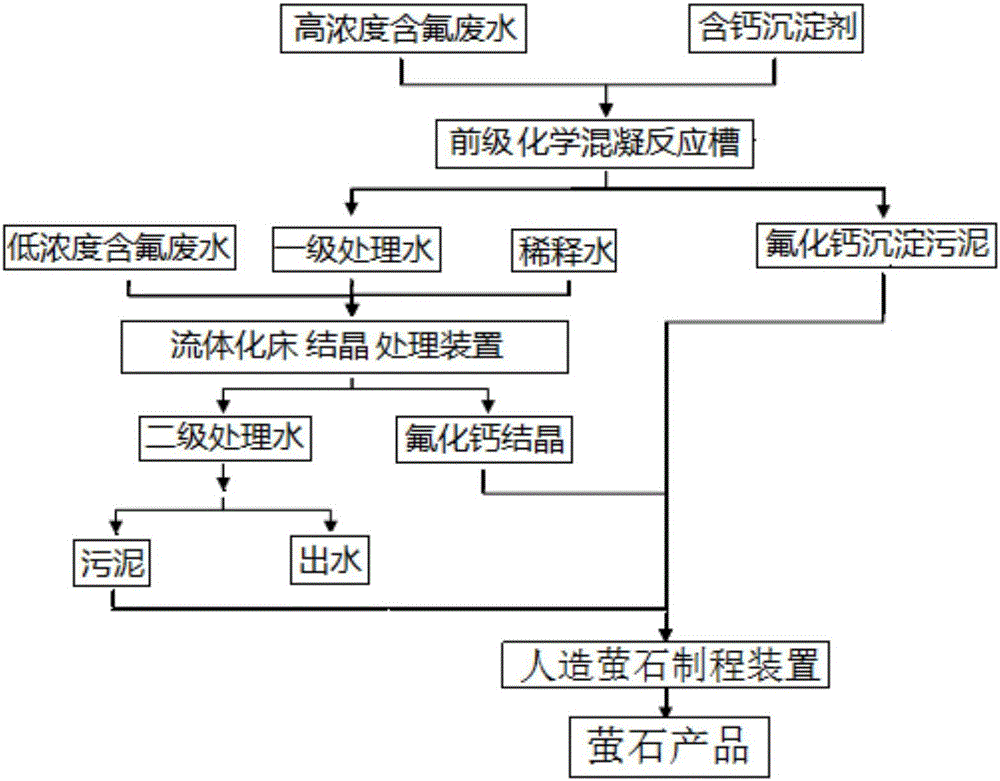

A waste water recycling and man-made technology, applied in water pollutants, water/sewage treatment, calcium/strontium/barium fluoride, etc., can solve the problems of high process cost, low calcium fluoride content, secondary pollution, etc. And the equipment is simple, the crystallization moisture content is low, and the effect of reducing fluorine pollution and

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

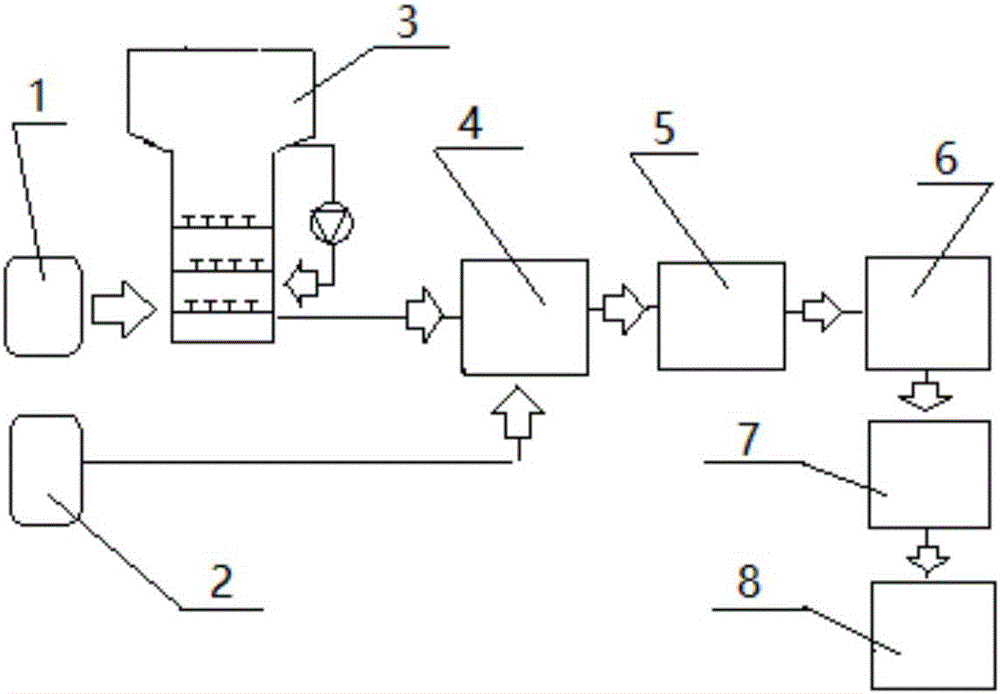

[0044] Embodiment 1: as attached figure 2 As shown, the fluorine-containing waste water tank 1 is connected to the fluidized bed 3, and there is a support in the fluidized bed 3, and the fluidized bed 3 is connected in series to enter the mixer 4, the dehumidification dryer 5, the bonding mixer 6, and the molding machine. Granulator 7, dryer 8, and fluorine-containing sludge tank 2 are directly connected to mixer 4 at the same time.

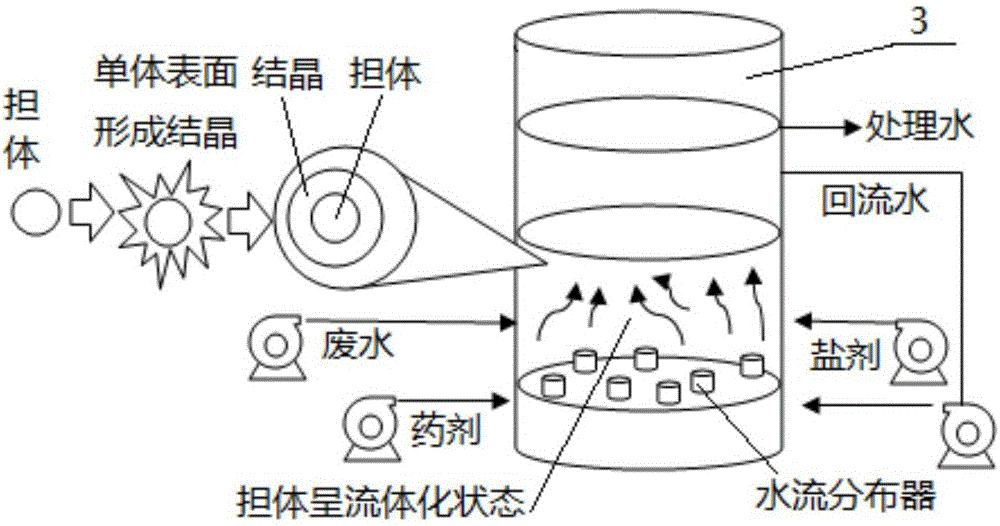

[0045] In the above, in the fluidized bed 3, the carrier is 0.2-0.5mm quartz sand, and the high-concentration fluorine-containing wastewater + CaCl 2 +Support→CaF 2 , Calcium fluoride crystals crystallize into spherical crystals with the support as the nucleus, with a particle size of 1-2mm, a purity of 90% to 95%, and some even up to 98%, and a moisture content of ≤10%.

[0046] In the foregoing, when quartz sand of 0.3-0.4 mm is selected, its radius increases three times through fluidized bed crystallization, and the volume of the obtained c...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| purity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com