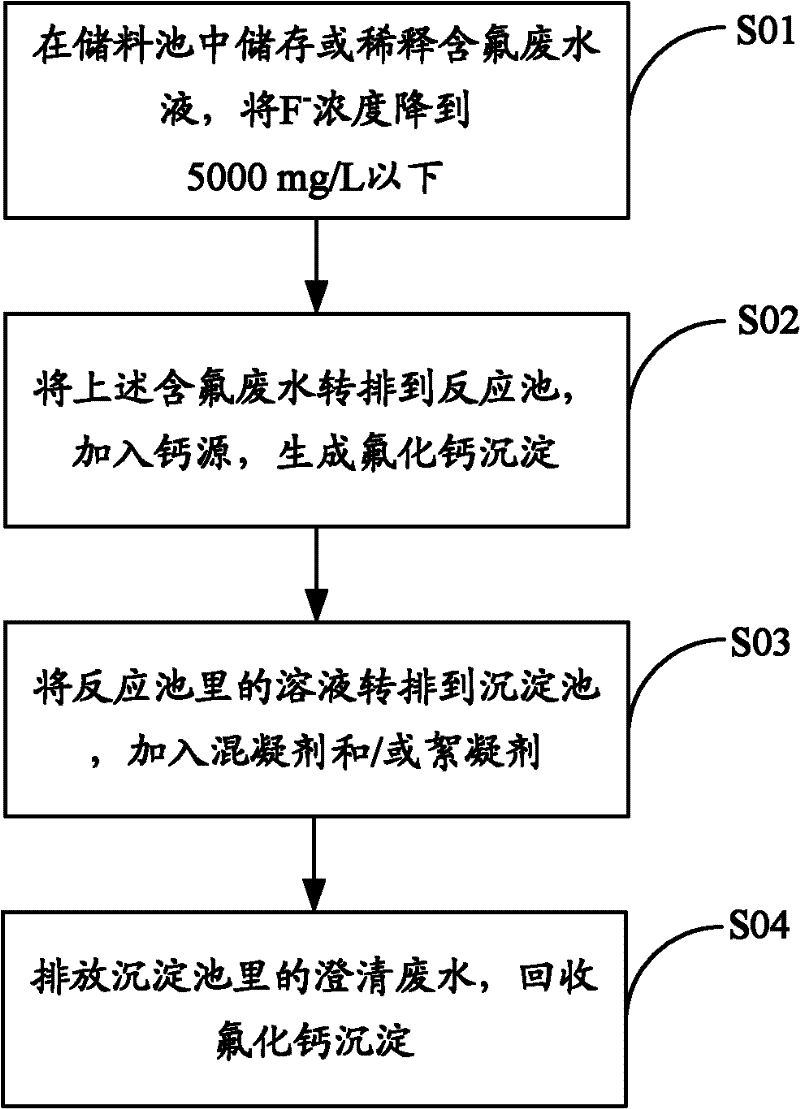

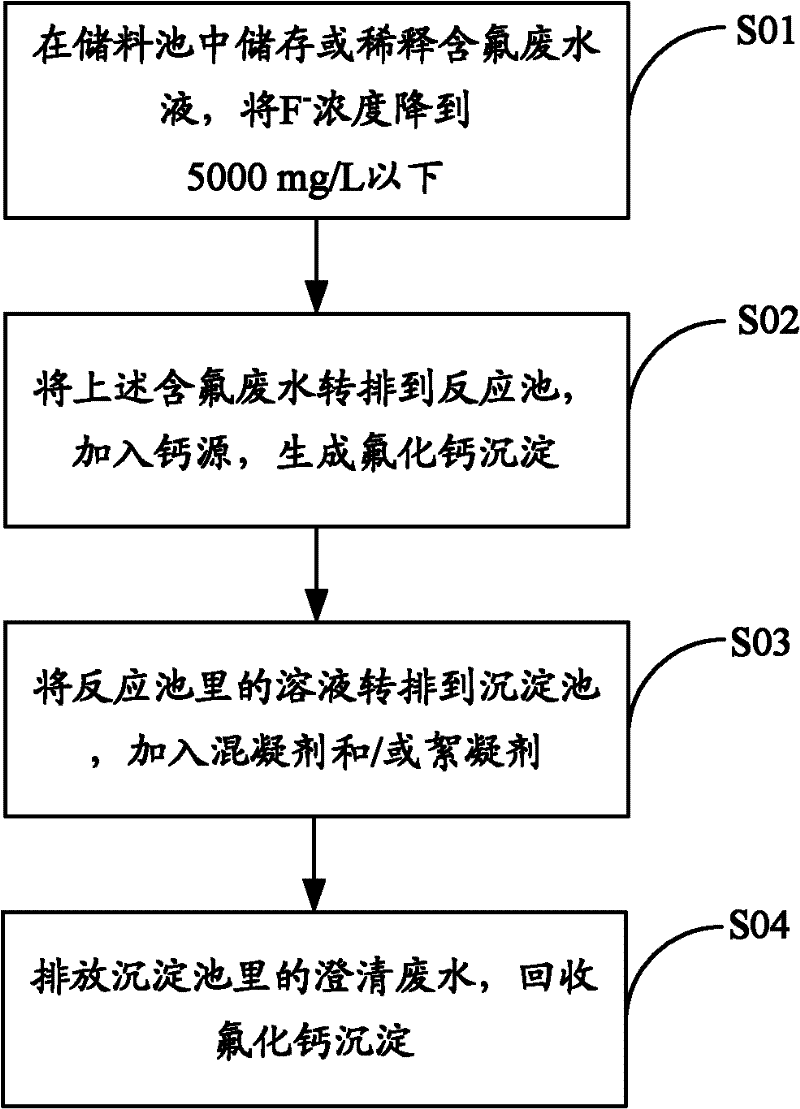

Treatment method of fluorine-containing waste water of solar cell plant

A technology of solar cells and treatment methods, which is applied in the fields of energy waste water treatment, water/sewage multi-stage treatment, water/sludge/sewage treatment, etc., can solve the problems of high cost and incomplete treatment of fluorine-containing waste water, and achieves easy operation. The effect of easy operation, high defluorination efficiency and high utilization value

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0032] The fluorine-containing waste acid is diluted to F in the storage tank - If the concentration is below 5000mg / L, it will be transferred to the reaction tank, and excessive slaked lime slurry (Ca(OH) 2 The molar mass is F - 2 times the total molar weight), so that the calcium source and F in the reaction pool - Fully reacted, the pH in the reaction pool was 7.4, and the F- concentration dropped to 15mg / L. Then it is discharged into the sedimentation tank, and about 0.8mg of aluminum chloride and 2mg of polyacrylamide are put into the mixed flocculant per liter of wastewater, stirred, left to settle, and the F-concentration of the supernatant is reduced to 6mg / L. Finally, the clarified neutral waste water is discharged, and the calcium fluoride precipitate is recovered.

Embodiment 2

[0034] The fluorine-containing waste acid liquid is diluted in the storage tank until the concentration of F- drops to 5000mg / L, then transferred to the reaction tank, and excessive slaked lime slurry (Ca(OH) 2 The molar mass is F - 2.5 times of the total molar weight), so that the calcium source in the reaction tank and F- fully react, the pH in the reaction tank=7.4, and the F-concentration drops to 15mg / L. Then it is discharged into the sedimentation tank, and about 1 mg of aluminum chloride and 2.5 mg of polyacrylamide are put into each liter of waste water, stirred, left to settle, and the F- concentration of the supernatant is reduced to 5 mg / L. Finally, the clarified neutral waste water is discharged, and the calcium fluoride precipitate is recovered.

Embodiment 3

[0036] The fluorine-containing waste acid solution is diluted in the storage tank until the concentration of F- drops to 5000mg / L, then transferred to the reaction tank, and 0.2mm limestone particles (CaCO 3 The molar mass is F - 4 times of the total molar amount) excess slaked lime slurry makes the calcium source in the reaction tank fully react with F-, the pH in the reaction tank=6.8, and the F-concentration drops to 20mg / L. Then it is discharged into the sedimentation tank, and about 0.8mg of aluminum chloride and polyacrylamide mixed with 0.8mg of flocculant are put into each liter of wastewater, stirred, left to settle, and the F-concentration of the supernatant is reduced to 7mg / L. Finally, the clarified neutral waste water is discharged, and the calcium fluoride precipitate is recovered.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com