Recycling processing method for wastewater produced by processing stainless steel

A treatment method, stainless steel technology, applied in metallurgical wastewater treatment, neutralized water/sewage treatment, oxidized water/sewage treatment, etc., can solve the problem of high concentration of heavy metals, and achieve the effect of high recovery value

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

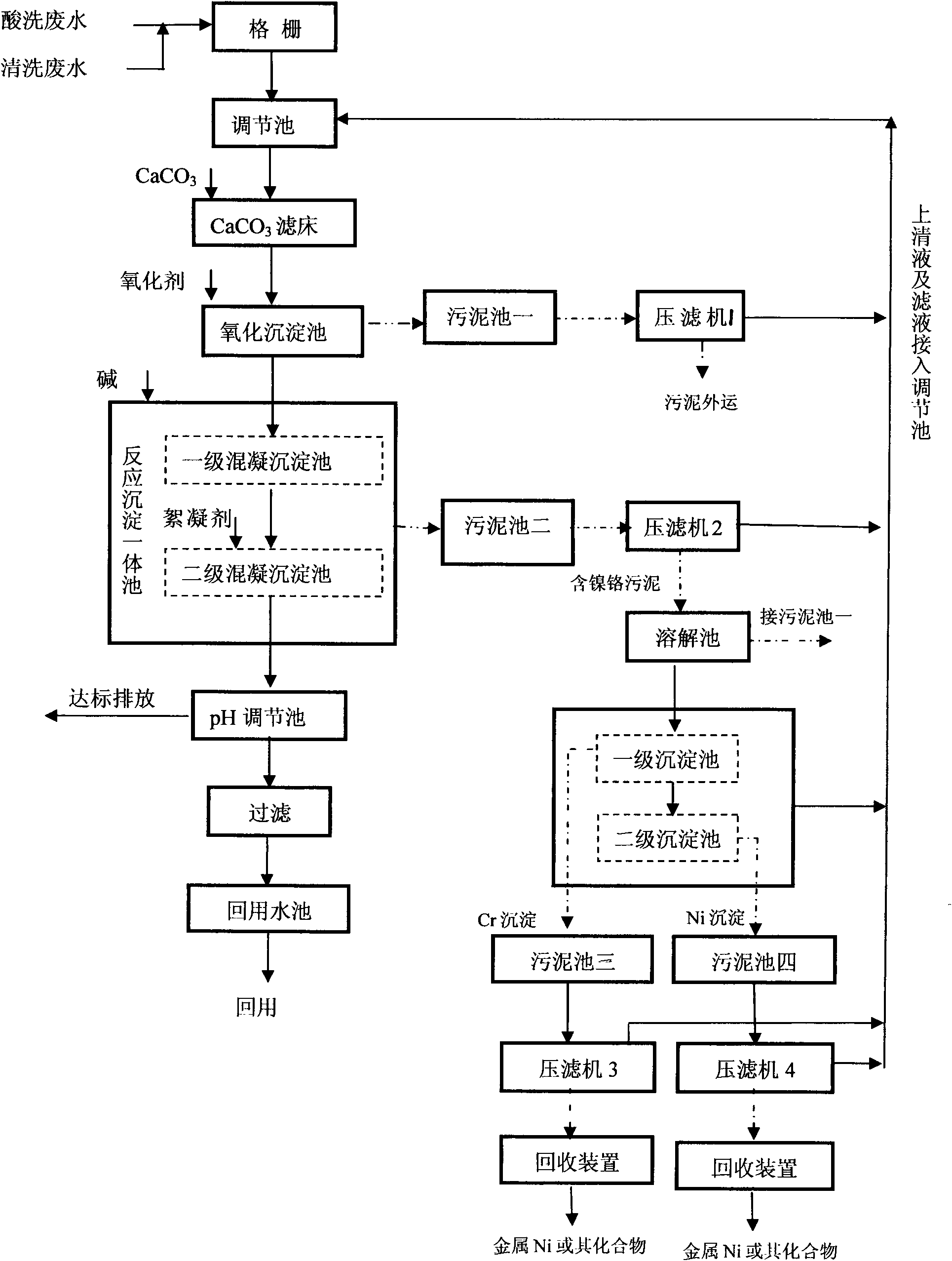

Image

Examples

Embodiment 1

[0052] A stainless steel pipe drawing enterprise produces 1200m of wastewater 3 / d, its acidity varies widely (H + concentration from 10 -1 change to 5mol / L), the specific water quality conditions are shown in Table 1.

[0053] Table 1 Water quality parameters (unit: mg / L)

[0054] COD Cr

SS

total chromium

total iron

Ni 2+

F -

300

200

500

1000

500

500

[0055] Utilize technique and equipment of the present invention to carry out the technological process of wastewater treatment as follows:

[0056] (1) The waste water passes through the grid to remove the large solid particles of the waste water, and the removal rate is greater than 80%. Then enter the regulating tank for homogenization.

[0057] (2) The wastewater in the regulating tank is pumped up to CaCO 3 filter bed, generating CaF 2 , F - Go greater than 90%. After the wastewater passes through the filter bed, the pH value is adjus...

Embodiment 2

[0065] A stainless steel decorative building material enterprise in a machinery factory produces 400m of wastewater 3 / d, the acidity of wastewater varies widely (H + concentration from 10 -3 changed to 2.5mol / L), the specific water quality conditions are shown in Table 2.

[0066] Table 2 Water quality parameters (unit: mg / L)

[0067] COD Cr

SS

total chromium

total iron

Ni 2+

F -

150~260

80~150

460

800

400

400

[0068] Utilize technique and equipment of the present invention to carry out the technological process of wastewater treatment as follows:

[0069] (1) The waste water passes through the grid to remove large solid particles in the waste water, and the removal rate is greater than 85%. Then enter the regulating tank for homogenization.

[0070] (2) The wastewater in the regulating tank is pumped up to CaCO 3 filter bed, generating CaF 2 , F - The removal rate is greater than 82%. ...

Embodiment 3

[0078] The waste water produced in the stainless steel parts processing workshop of a large-scale comprehensive machinery factory in an industrial park is 2000m 3 / d, the acidity of wastewater varies widely (H + concentration from 10 -4 change to 1mol / L), the specific water quality conditions are shown in Table 3.

[0079] Table 3 Water Quality Parameters (Unit: mg / L)

[0080] COD Cr

SS

total chromium

total iron

Ni 2+

F -

200~300

150~300

500~600

1000~1200

500~600

450~650

[0081] Utilize technique and equipment of the present invention to carry out the technological process of wastewater treatment as follows:

[0082] (1) The waste water passes through the grid to remove the large solid suspended matter in the waste water, and the removal rate is greater than 80%. Then enter the regulating tank for homogenization.

[0083] (2) The wastewater in the regulating tank is pumped up to CaCO 3 fil...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com