Method for using aluminum ash to prepare aluminum polychlorid and co-produce calcium fluoride

A technology of polyaluminum chloride and co-production of calcium fluoride, which is applied in the fields of aluminum chloride, chemical instruments and methods, aluminum halide, etc., and can solve problems such as air pollution, no systematic process, and no consideration of the direction of fluoride

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

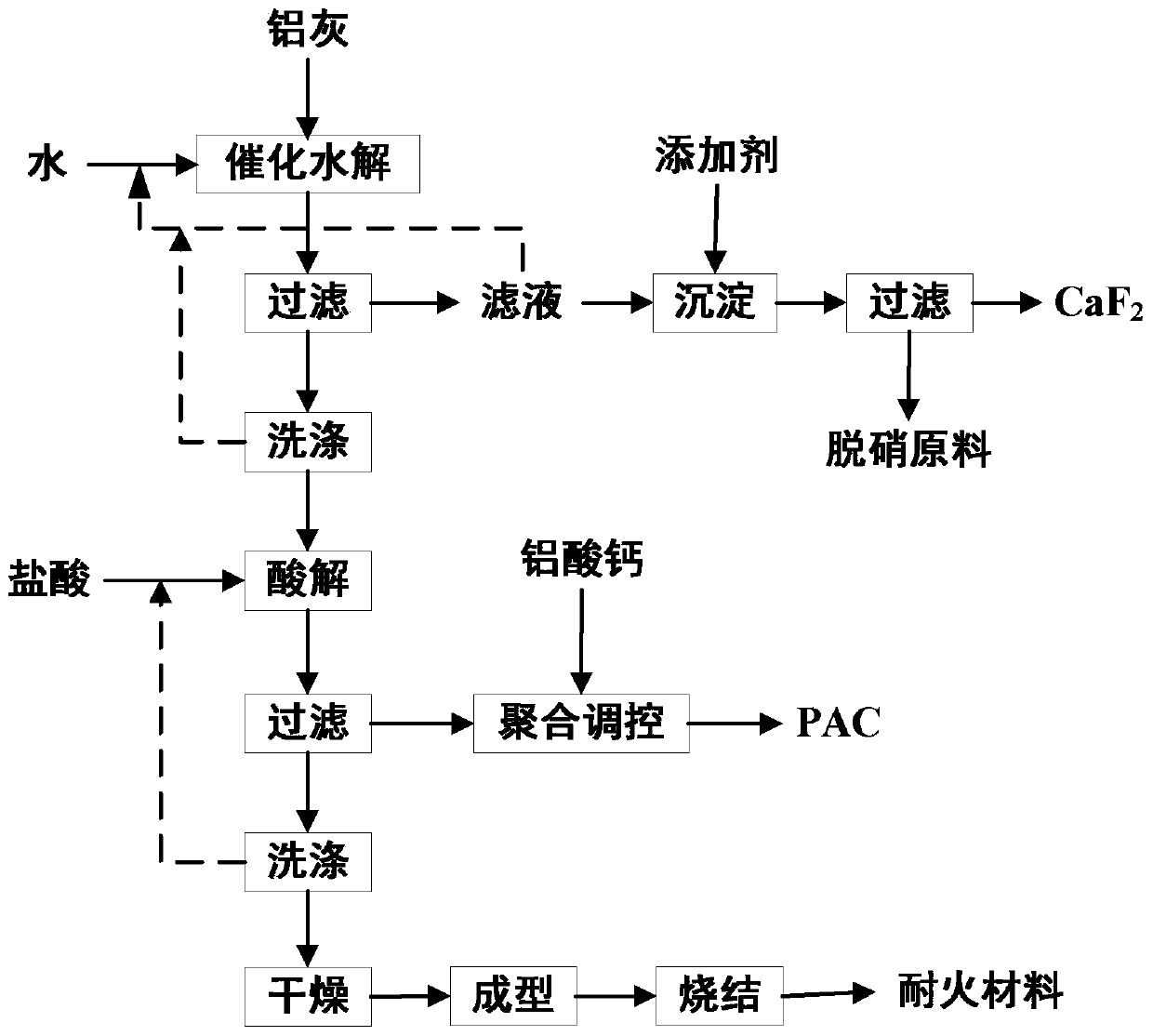

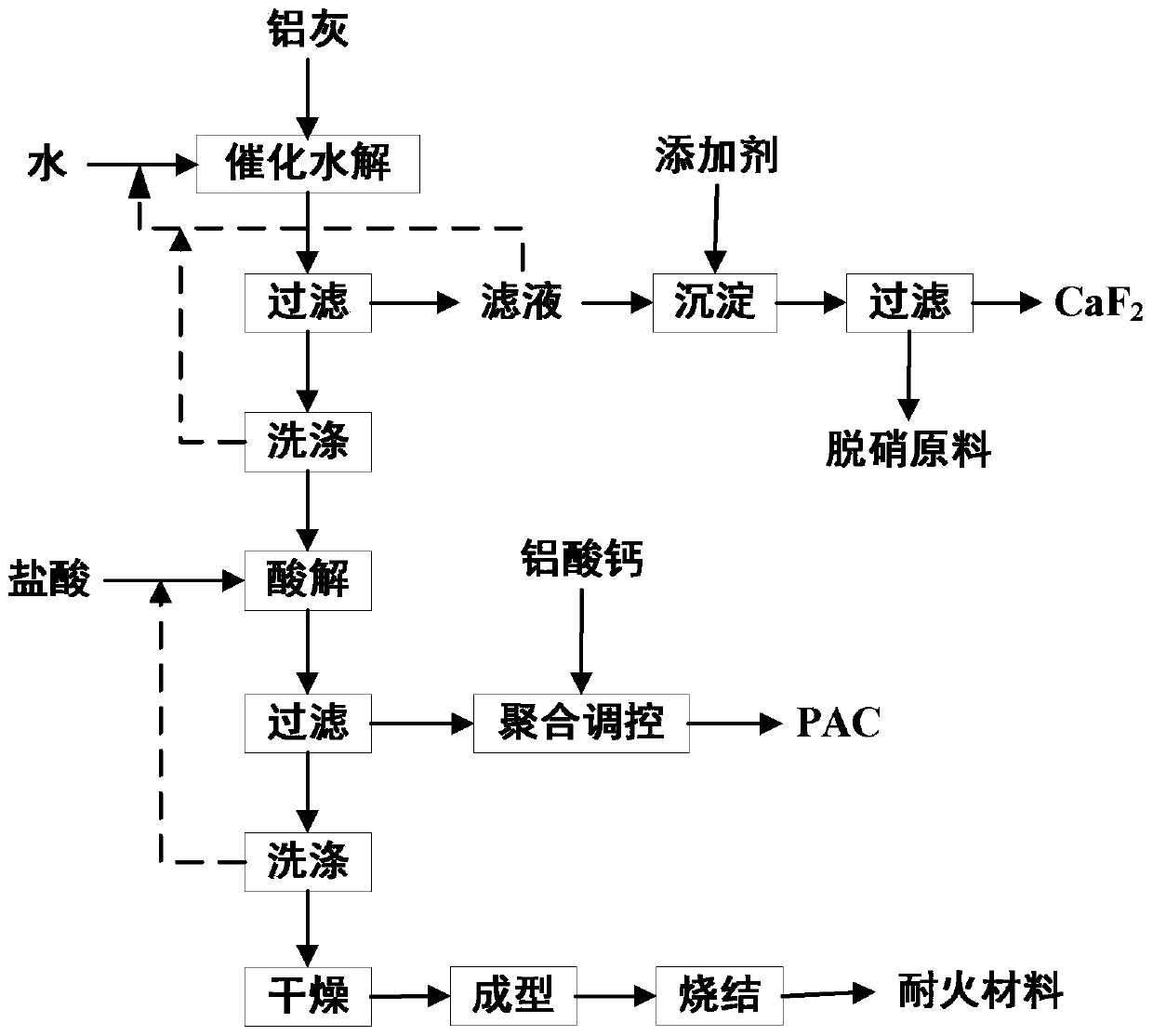

Method used

Image

Examples

Embodiment 1

[0022] The aluminum ash is treated according to the process of catalytic hydrolysis-acidolysis, catalytic hydrolysis section: liquid-solid ratio 2ml / g, reaction temperature 70°C, reaction time 1h, hydrolyzate circulation times 3 times; acidolysis section: liquid-solid ratio 3ml / g g, reaction temperature 80°C, reaction time 1h, hydrochloric acid concentration 100g / l. Industrial calcium fluoride and polyaluminum chloride were prepared, the content of polyaluminum chloride was 6.2% alumina, the basicity was 80%, the content of ammonia nitrogen was 0.02%, and the content of fluorine was 0.03%.

Embodiment 2

[0024] The aluminum ash is treated according to the process of catalytic hydrolysis-acidolysis, catalytic hydrolysis section: liquid-solid ratio 3ml / g, reaction temperature 85°C, reaction time 2h, hydrolyzate cycle times 5 times; acidolysis section: liquid-solid ratio 4ml / g g, reaction temperature 80°C, reaction time 1h, hydrochloric acid concentration 150g / l. Industrial calcium fluoride and polyaluminum chloride are prepared, the content of polyaluminum chloride is 6% alumina, the basicity is 70%, the content of ammonia nitrogen is 0.01%, and the content of fluorine is 0.02%.

Embodiment 3

[0026] The aluminum ash is treated according to the process of catalytic hydrolysis-acidolysis, catalytic hydrolysis section: liquid-solid ratio 3ml / g, reaction temperature 95°C, reaction time 3h, hydrolyzate cycle times 6 times; acidolysis section: liquid-solid ratio 5ml / g g, reaction temperature 95°C, reaction time 2h, hydrochloric acid concentration 200g / l. Industrial calcium fluoride and polyaluminum chloride are prepared, the content of polyaluminum chloride is 10% alumina, the basicity is 65%, the content of ammonia nitrogen is 0.009%, and the content of fluorine is 0.001%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com