A joint treatment method for sweet sorghum plants rich in heavy metals

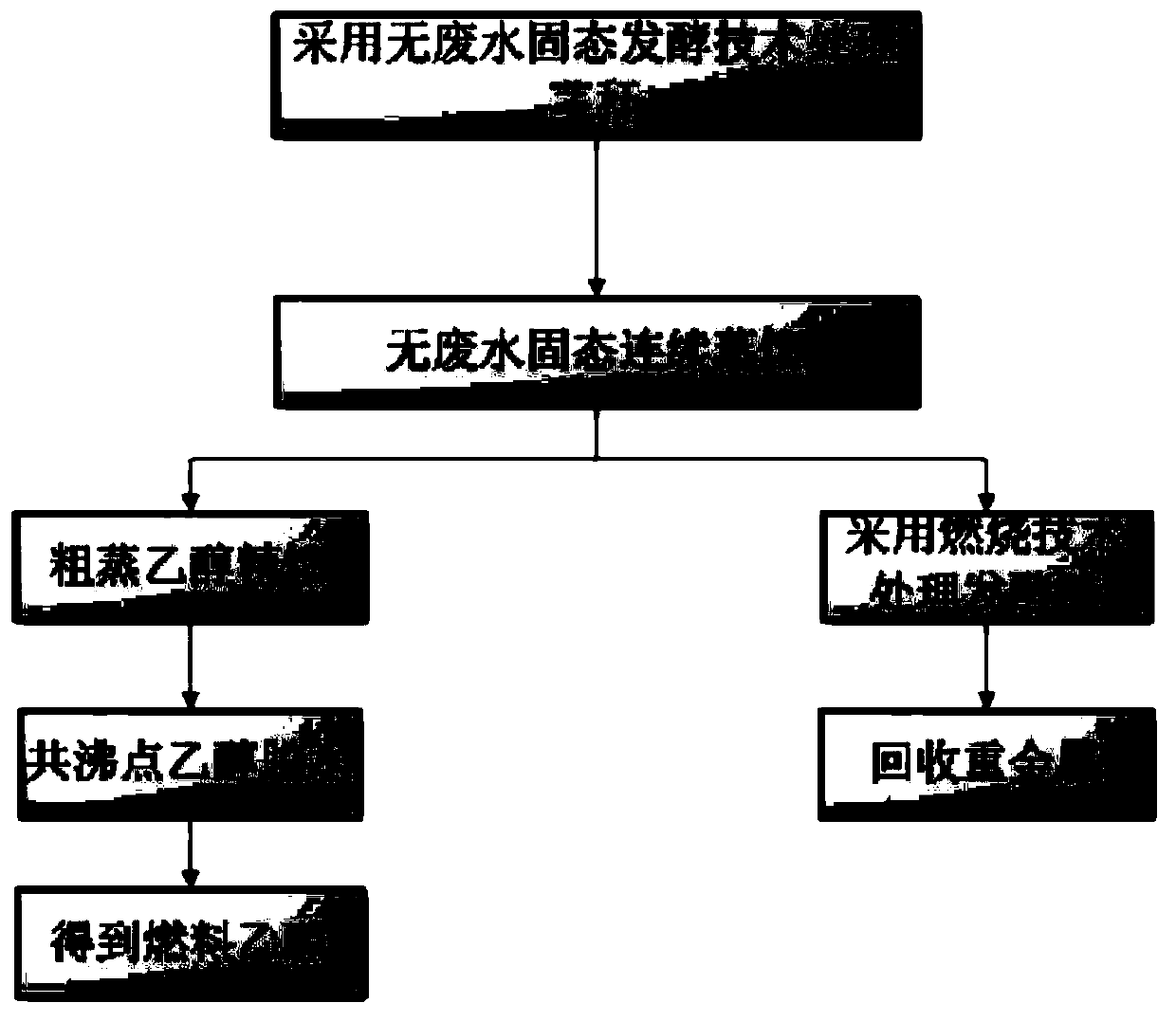

A heavy metal and sweet sorghum technology, which is applied in the field of joint disposal of sweet sorghum plants rich in heavy metals, can solve problems such as difficulty in squeezing juice, uncontrollable discharge of heavy metals in wastewater, water pollution, etc., and achieve the effect of shortening the fermentation time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0035] Embodiment 1 The solid-state fermentation technology of sweet sorghum stalk

[0036] The sweet sorghum used in the test was planted in cadmium-contaminated farmland in Shaoguan, Guangdong. The cadmium concentration in the soil was 7.93mg / kg, the effective cadmium content was 2.89mg / kg, the sugar content of the stem was 11.3%, and the fresh weight was 750g / plant. Adopting advanced solid state fermentation (ASSF) technology and unique strains with high temperature resistance and high metabolic efficiency (the strain is Saccharomyces cerevisiae Hansen) TSH2, the main fermentation time is completed within 20 hours, the ethanol yield is over 90%, and the whole process Almost no waste water is produced, effectively reducing the secondary pollution of heavy metals.

[0037] The specific operation method is as follows: strip the fresh sweet sorghum stalk leaves and pulverize and mix evenly (diameter 1-5mm, length less than 50mm), weigh 10kg of pulverized material, and insert th...

Embodiment 2

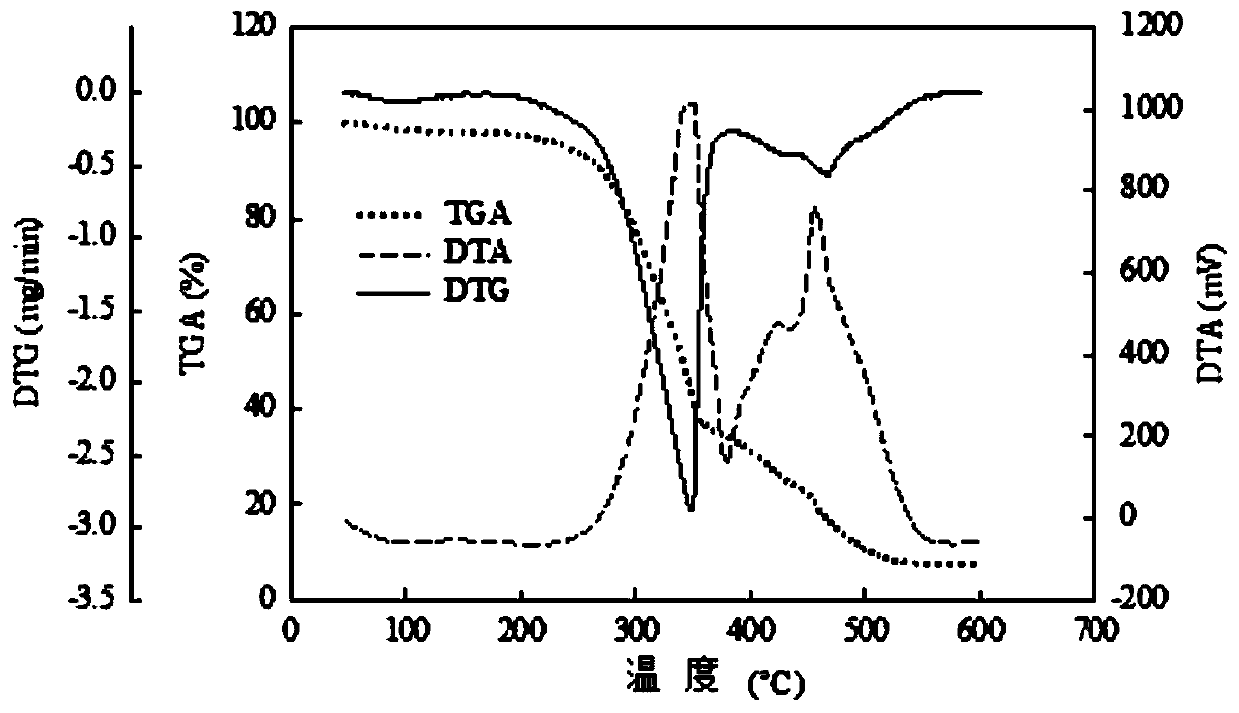

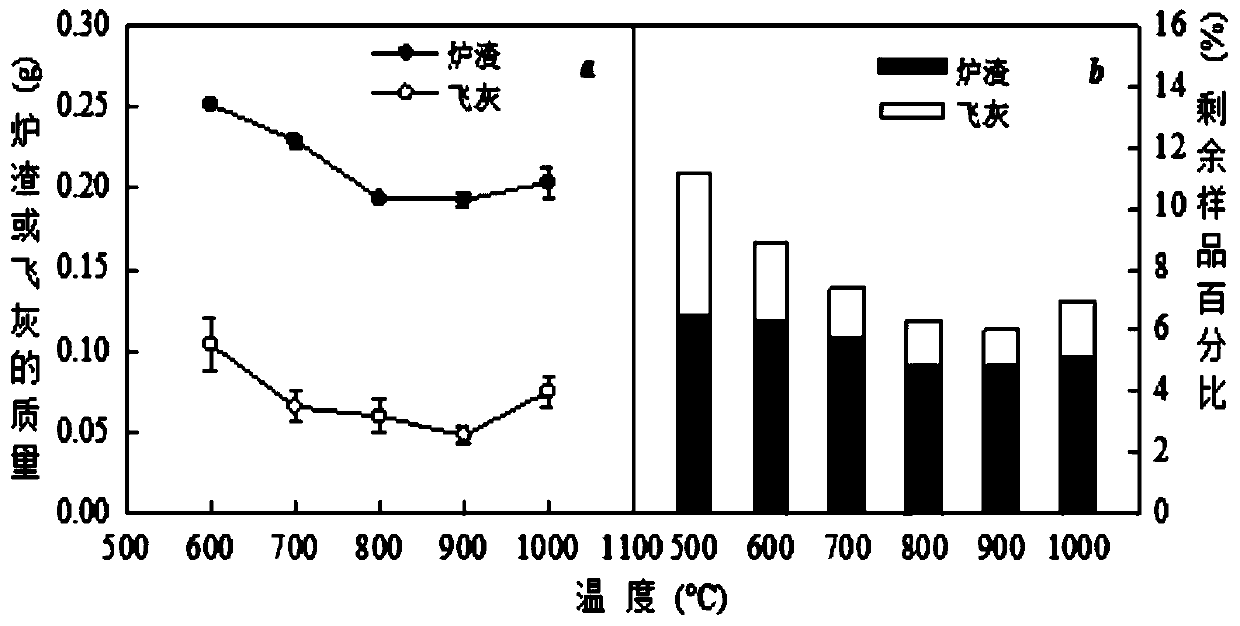

[0039] Example 2 Combustion technology of sweet sorghum stalk fermentation residue and waste

[0040] Using tube furnace combustion technology, the combustion system consists of gas distribution system, tube furnace, fly ash collection system and flue gas absorption system. The gas distribution system consists of gas cylinders, valves and gas flow meters to control the gas flow rate. The tube furnace uses SK2-4-10 high-temperature tube furnace as the burner, and the furnace temperature can be set arbitrarily at 500-1200 °C according to the experimental needs. The fly ash produced by combustion is filtered and collected by the glass fiber filter cartridge in the filter cartridge holder. The flue gas absorption system consists of a series of absorption bottles filled with 5% HNO 3 +10%H 2 o 2 The mixed solution is used to absorb gaseous heavy metals.

[0041] The specific operation method is: accurately weigh 4.000g of sweet sorghum stalk fermentation residue, study the mig...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com