Method and device for treating fluorine-containing waste water

A treatment method and technology of a treatment device, which are applied in the field of environmental engineering, can solve the problems of large influence of fluoride ion removal, difficulty in maintaining lasting production, stable operation, and narrow range of pH value requirements.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach 1

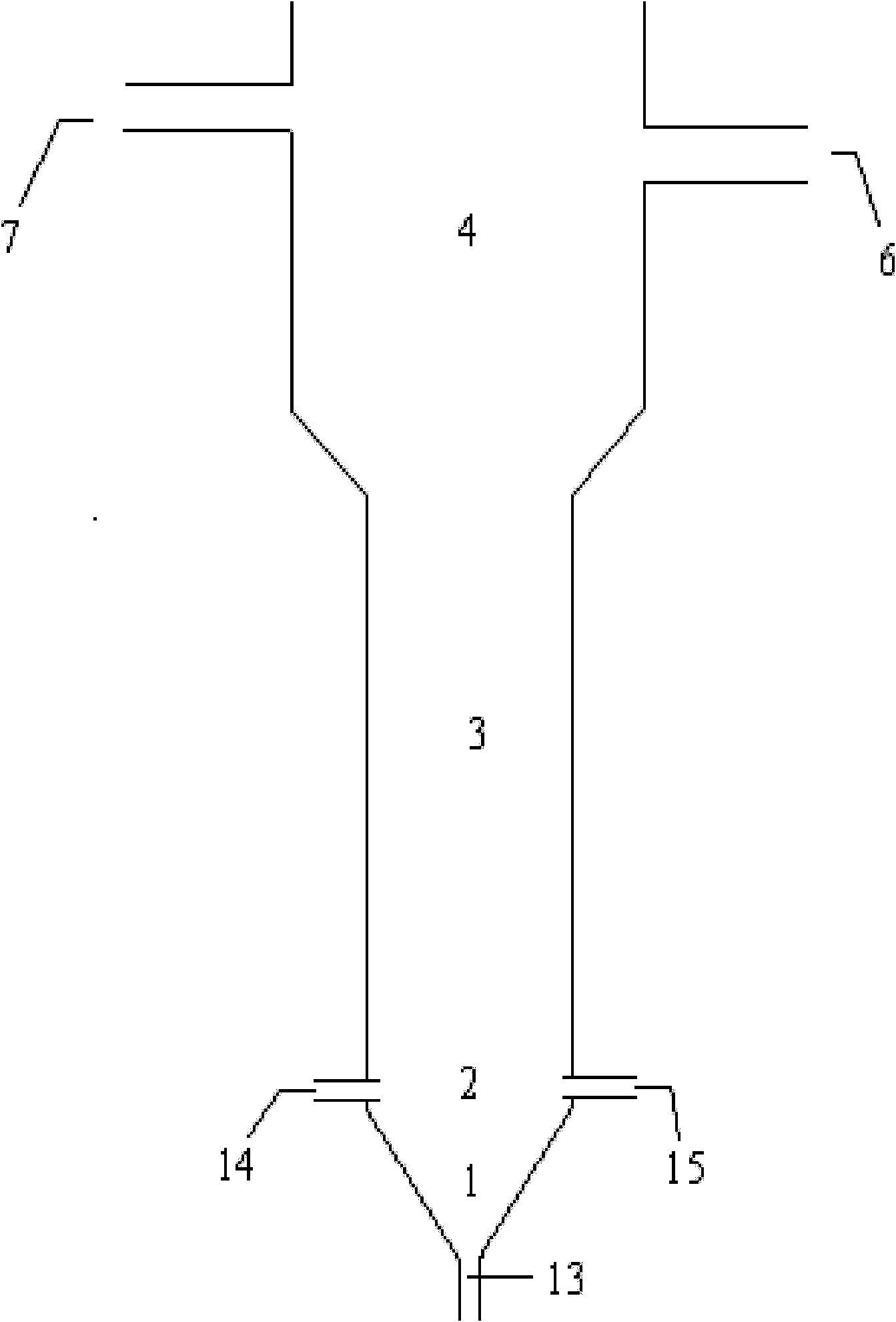

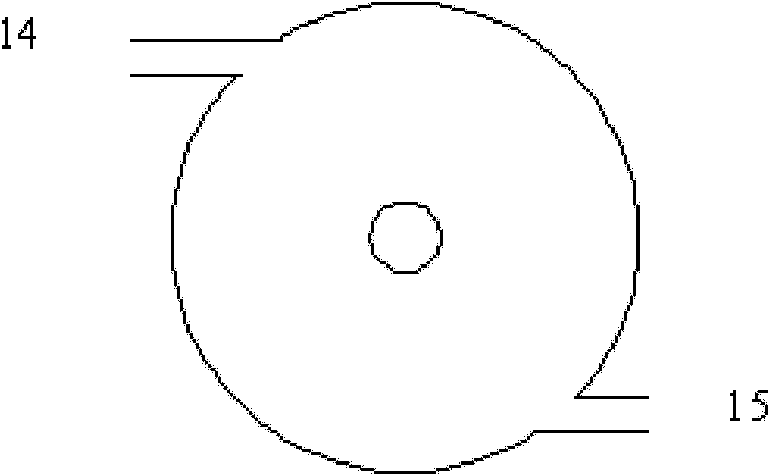

[0028] Embodiment 1: Combining figure 1 , figure 2 Explain the structure of the treatment device, which is mainly composed of calcium fluoride sludge settlement area 1, fluorine-containing wastewater-calcium-containing precipitant mixing area 2, fluidized crystallization area 3, solid-liquid separation area 4, fluorine-containing wastewater and calcium-containing precipitation The agent is added through the fluorine-containing wastewater inlet pipe 14 and the calcium-containing precipitating agent inlet pipe 15 respectively, and is treated by fluidized bed crystal seed crystallization and precipitation; coarse particles settle into the calcium fluoride sludge settlement area, and some fine particles of calcium fluoride enter the solid-liquid Separation zone: fine-grained calcium fluoride is settled and separated in the solid-liquid separation zone, part of the effluent (i.e. primary treatment water) flows back into the calcium-containing precipitant inlet pipe 15 through the ...

Embodiment approach 2

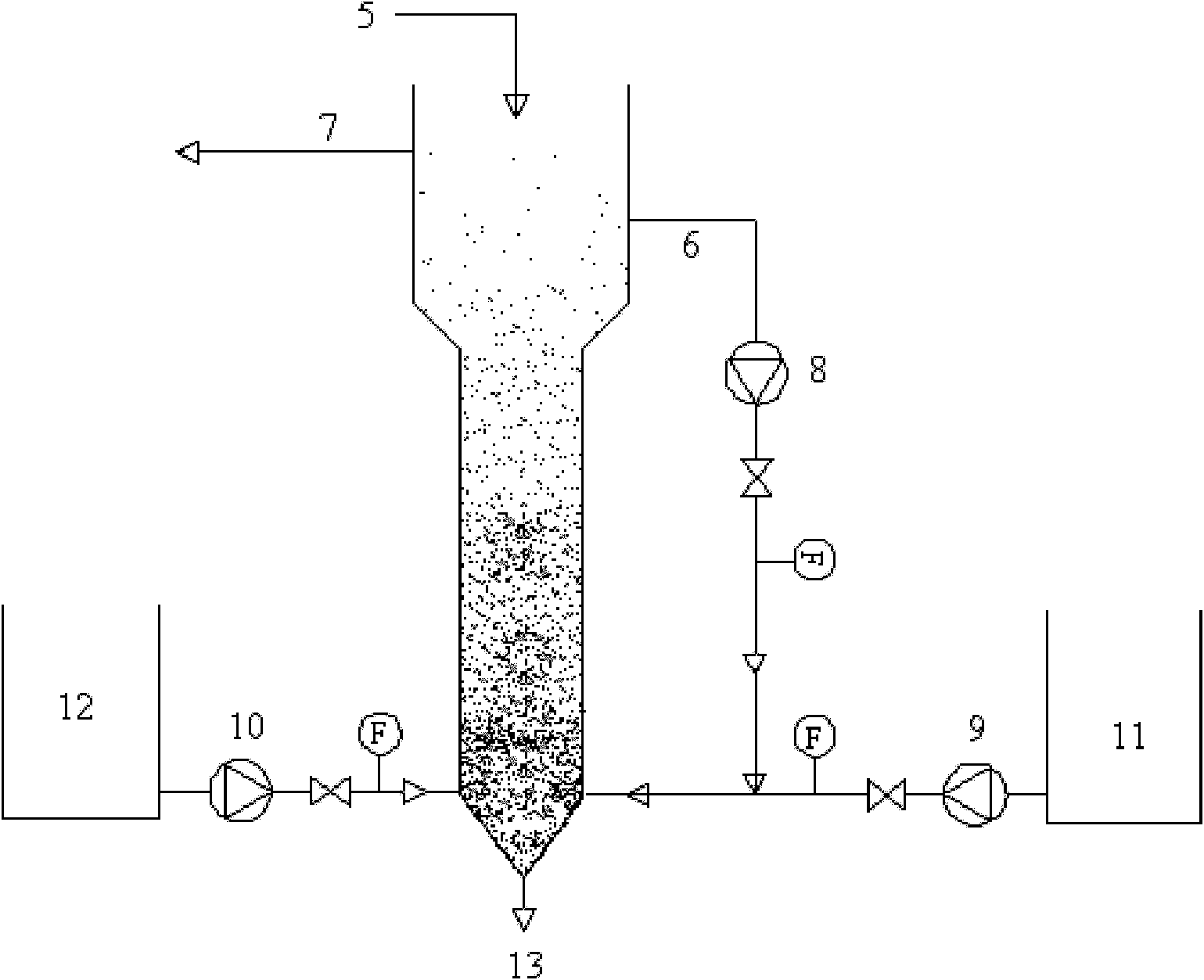

[0029] Embodiment 2: Combining figure 1 , figure 2 , image 3To illustrate the fluorine-containing wastewater treatment process, a certain amount of calcium fluoride seeds with a particle size of 10 μm-100 μm is added to the treatment device from the top inlet 5 of the cylindrical fluidized bed body, and the calcium-containing precipitant water tank 11 and the fluorine-containing wastewater tank 12 The calcium-containing precipitant and the fluorine-containing wastewater are sent to the fluoride-containing wastewater-calcium-containing precipitant mixing zone 2 through the second water pump 9 and the third water pump 10 according to the reaction ratio, and the influent flow rate is adjusted to maintain the concentration of the calcium fluoride seed crystal. Fluidization, the rising speed of the solution is 0.01-0.05m / s, and the pH of the solution in the fluidized bed is adjusted to 2-5. After fully reacting, the coarse calcium fluoride particles enter the calcium fluoride sl...

Embodiment 1

[0031] see figure 1 , figure 2 , image 3 With Embodiment 1 and Embodiment 2, 150g of calcium fluoride seeds with an average particle diameter of 19 μm are added to a treatment device with a volume of 5L in the fluidized bed reaction zone, and Ca(OH) 2 The supernatant is used as a precipitant, and the volume ratio of the precipitant to the fluorine-containing wastewater is adjusted to be 4:1 (wastewater concentration 3100mg / L, pH=2.94), Ca / F=1.2:2, and the rising speed of the solution is 0.02m / s. Reaction pH to 4.0, discharge calcium fluoride precipitation sludge and dry after reaction, see Figure 4 , it can be seen that the calcium fluoride obtained by the reaction is sandy, the particle size is large, the moisture content of the sediment after filtration is 37%, and the content of calcium fluoride after drying is 96%, which can be reused as raw materials for production, and the primary treatment of water fluoride ions The concentration is 28mg / L. Send the primary treat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com