Gradient copper-based alloy cable conductor and manufacturing method thereof

A copper-based alloy, cable conductor technology, applied in cable/conductor manufacturing, metal/alloy conductors, conductors, etc., can solve the problem that the electrical properties and mechanical properties of cable conductors cannot be simultaneously improved, and achieve lattice distribution. Good transition, excellent mechanical strength, less signal reflection and refraction effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0037] Embodiment 1: A gradient copper-based alloy cable conductor and its manufacturing method

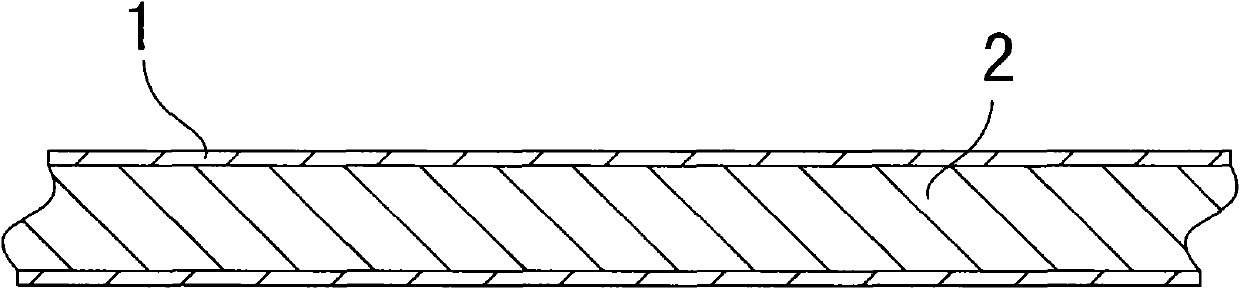

[0038] as attached figure 1 As shown, a gradient copper-based alloy cable conductor is composed of a core layer 1 and a skin layer 2. The core layer 1 and the skin layer 2 form a bimetallic concentric circle structure, wherein the core layer 1 is a copper-based alloy, and the The skin layer 2 is high-purity cathode copper whose mass percentage of copper is greater than or equal to 99.99%. The copper-based alloy is indium-tin-copper alloy, wherein the mass percentage among indium, tin and copper is indium:tin:copper=0.2:0.19:99.61. The cross-sectional area ratio of the core layer and the skin layer is 90:10.

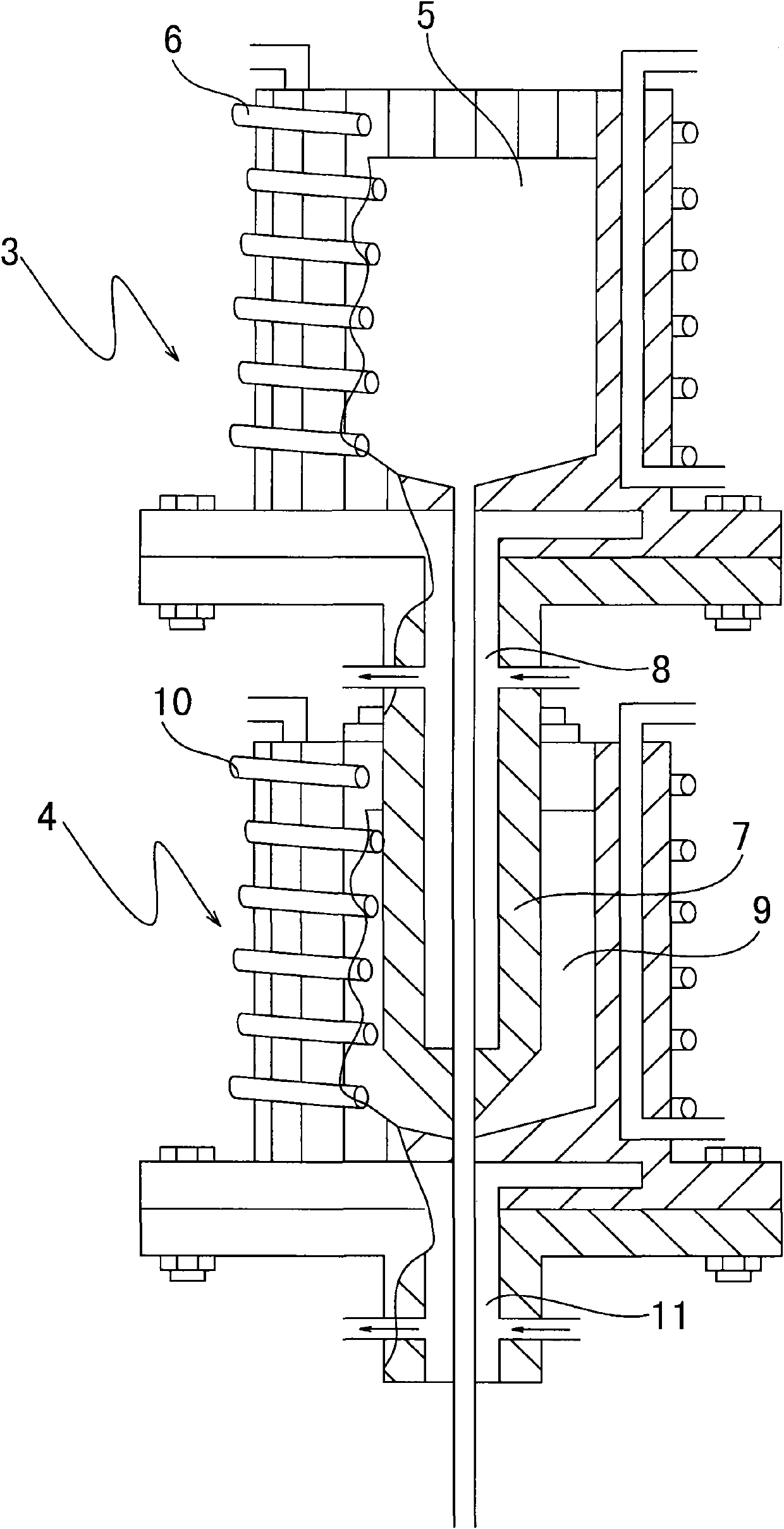

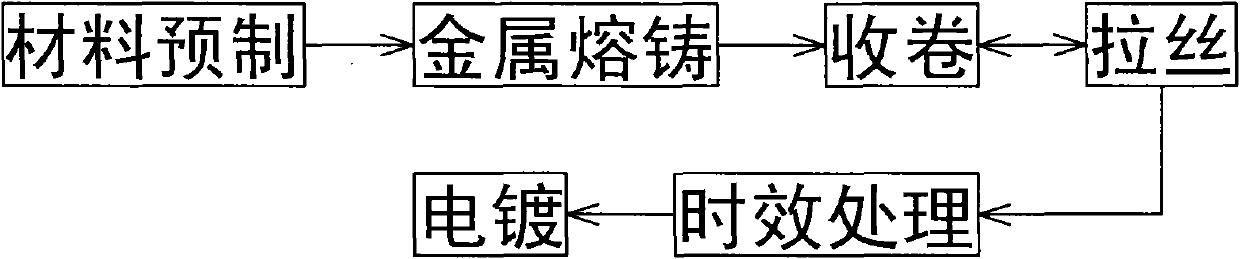

[0039] The flow chart of the manufacturing method of gradient copper-based alloy cable conductor is as attached figure 2 As shown, the melting and casting process of this method needs to be used as attached image 3 The double-layer composite material one-time casting mo...

Embodiment 2

[0041] Embodiment 2: A gradient copper-based alloy cable conductor and its manufacturing method

[0042] A gradient copper-based alloy cable conductor, consisting of a core layer and a skin layer, the core layer and the skin layer form a bimetallic concentric circle structure, wherein the core layer is a copper-based alloy, and the skin layer is the mass percentage of copper Greater than or equal to 99.9% standard cathode copper. The copper-based alloy is a beryllium-copper alloy, wherein the mass percentage between beryllium and copper is beryllium:copper=1.8-2.0:96.8-97.1. The cross-sectional area ratio of the core layer and the skin layer is 75:25.

[0043] The melting and casting process of the manufacturing method of the gradient copper-based alloy cable conductor is the same as the first embodiment.

Embodiment 3

[0044] Embodiment 3: A gradient copper-based alloy cable conductor and its manufacturing method

[0045] A gradient copper-based alloy cable conductor, mainly composed of a core layer and a skin layer, the core layer and the skin layer form a bimetallic concentric circle structure, wherein the core layer is a copper-based alloy, and the skin layer is a mass percent of copper High-purity cathode copper with a content greater than or equal to 99.99%. The copper-based alloy is a lanthanum-copper alloy, wherein the mass percentage between lanthanum and copper is lanthanum:copper=0.05-0.1:99.9-99.95. The cross-sectional area ratio of the core layer and the skin layer is 80:20. The outer surface of the skin layer is coated with a metal thin film layer, the metal of the metal thin film layer is silver, and the thickness of the coating layer is 3 μm.

[0046] The melting and casting process of the manufacturing method of the gradient copper-based alloy cable conductor is the same as...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com