Method for preparing high-purity peanut skin procyanidine

A technology of red-clothed raw flowers and peanut-red-clothed, which is applied in the biological field, can solve the problems of reduced product added value, low product purity, and low yield, and achieve the effects of improving product quality, safety, high purity, and easy absorption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

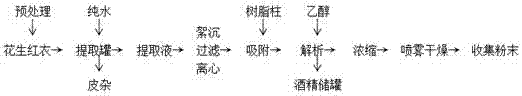

Image

Examples

Embodiment 1

[0024] A preparation method of high-purity peanut red proanthocyanidins, comprising the steps of:

[0025]

[0026] Specifically include the following steps:

[0027] (1) Pick up the material from the raw material warehouse, send it to the pretreatment room for dust removal, stone removal, color selection and selection, remove all impurities and mildewed raw materials, and perform ozone treatment and ultraviolet irradiation to remove aflatoxin to obtain 500kg Peanut red coat raw material.

[0028] (2) Pour the raw materials into the extraction tank, feed while adding water, the weight ratio of material to liquid is 1:9, the temperature in the extraction tank rises to 40°C for 2 hours, reflux for 10 minutes every 0.5 hours, and the extract passes through a 100-mesh screen Sieve and filter into a temporary storage tank, add 6 times the volume of water to the remaining filter residue, keep at 40°C for 1 hour, reflux for 10 minutes every 0.5 hours, and combine the extracts in ...

Embodiment 2

[0034] A preparation method of high-purity peanut red proanthocyanidins, comprising the steps of:

[0035] (1) Pick up the material from the raw material warehouse, send it to the pretreatment room for dust removal, stone removal, color selection and selection, remove all impurities and mildewed raw materials, and perform ozone treatment and ultraviolet irradiation to remove aflatoxin to obtain 500kg Peanut red coat raw material.

[0036](2) Pour the raw materials into the extraction tank, feed while adding water, the ratio of material to liquid is 1:9, the temperature in the extraction tank rises to 45°C and keeps for 2.5 hours, reflux for 10 minutes every 0.5 hours, and the extract is passed through a 100-mesh screen Sieve and filter into the temporary storage tank, add 7 times the volume of water to the remaining filter residue, keep at 45°C for 0.5h, reflux for 10min every 0.5h, and combine the extracts in the temporary storage tank.

[0037] (3) Add 0.02% food-grade poly...

Embodiment 3

[0042] A preparation method of high-purity peanut red proanthocyanidins, comprising the steps of:

[0043] (1) Pick up the material from the raw material warehouse, send it to the pretreatment room for dust removal, stone removal, color selection and selection, remove all impurities and mildewed raw materials, and perform ozone treatment and ultraviolet irradiation to remove aflatoxin to obtain 500kg Peanut red coat raw material.

[0044] (2) Pour the raw materials into the extraction tank, feed while adding water, the ratio of material to liquid is 1:8, the temperature in the extraction tank rises to 50°C for 2 hours, and refluxes for 10 minutes every 0.5 hours, and the extract is passed through a 100-mesh screen Filter and put it into a temporary storage tank, add 4 times the volume of water to the remaining filter residue, keep at 50°C for 2 hours, reflux every 0.5 hours for 10 minutes, and combine the extracts in the temporary storage tank.

[0045] (3) Add 0.04% food-gra...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com